THE Donut MotorS

Greater torque and power. Lower cost and weight.

Powering next-gen electric vehicles

ELECTRIC MOTORS WITH INSANE PERFORMANCE

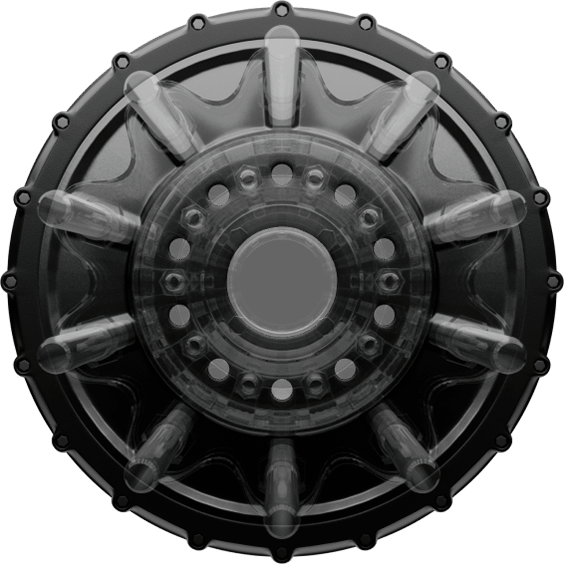

Automotive (21”)

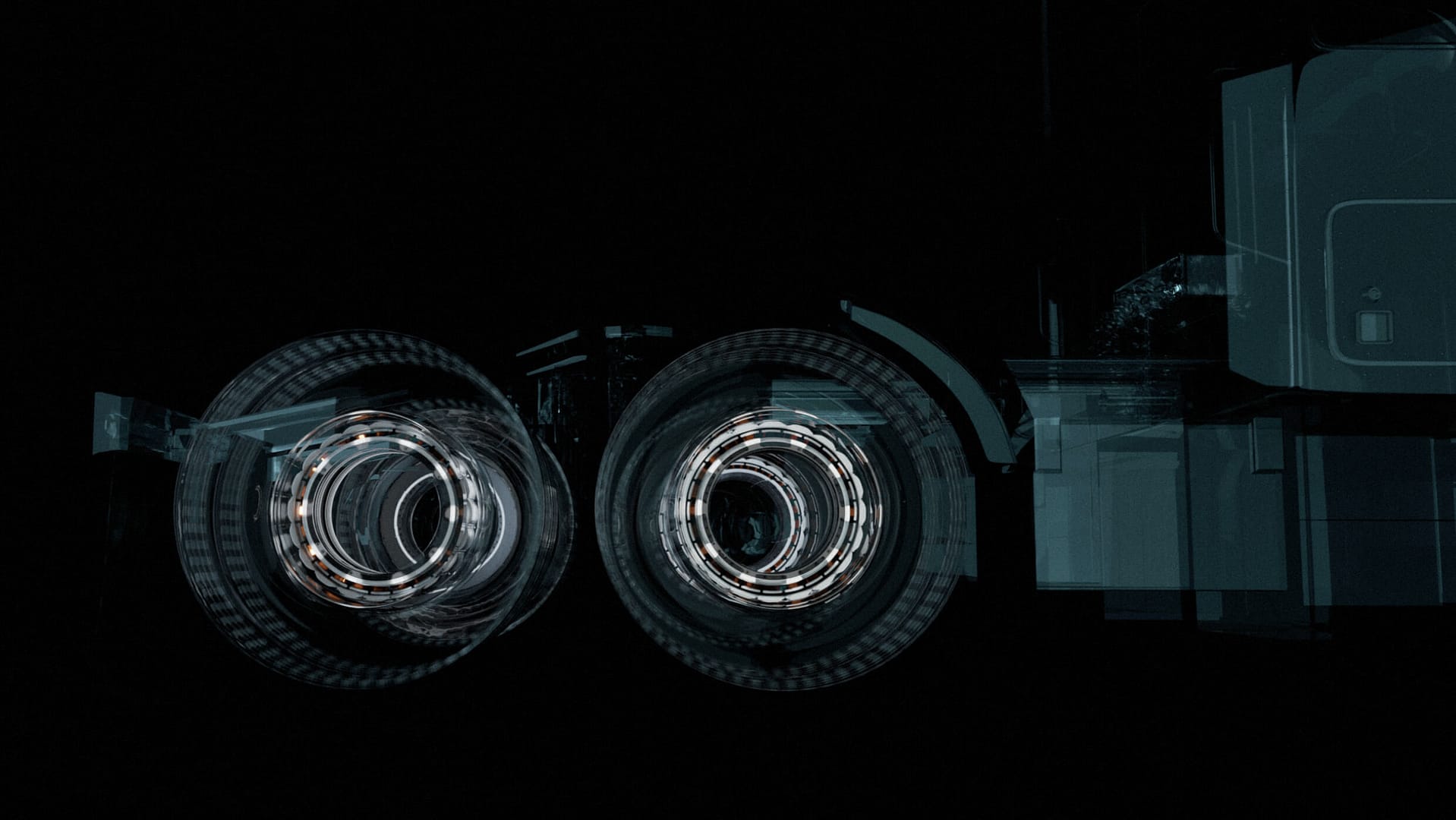

Semi-Truck (21”)

Motorcycle (17”)

Scooter (12”)

Drone (120mm)

Automotive (21”)

Semi-Truck (21”)

Motorcycle (17”)

Scooter (12”)

Drone (120mm)

Optimized for high performance, reducing mass in the wheel and the connection points.

630 kW Power

4300 Nm Torque

40 kg Mass

Optimized for heavy-duty durability and powerful performance.

200 kW Power

3000 Nm Torque

40 kg Mass

Optimized for lightness, reducing mass in the wheel and the swingarm.

150 kW Power

1200 Nm Torque

21 kg Mass

Optimized for improved efficiency, cooling, and reduced use of active materials.

15 kW Power

300 Nm Torque

8 kg Mass

Optimized for high performance and efficiency in a compact package.

3 kW Power

20 Nm Torque

1.5 kg Mass

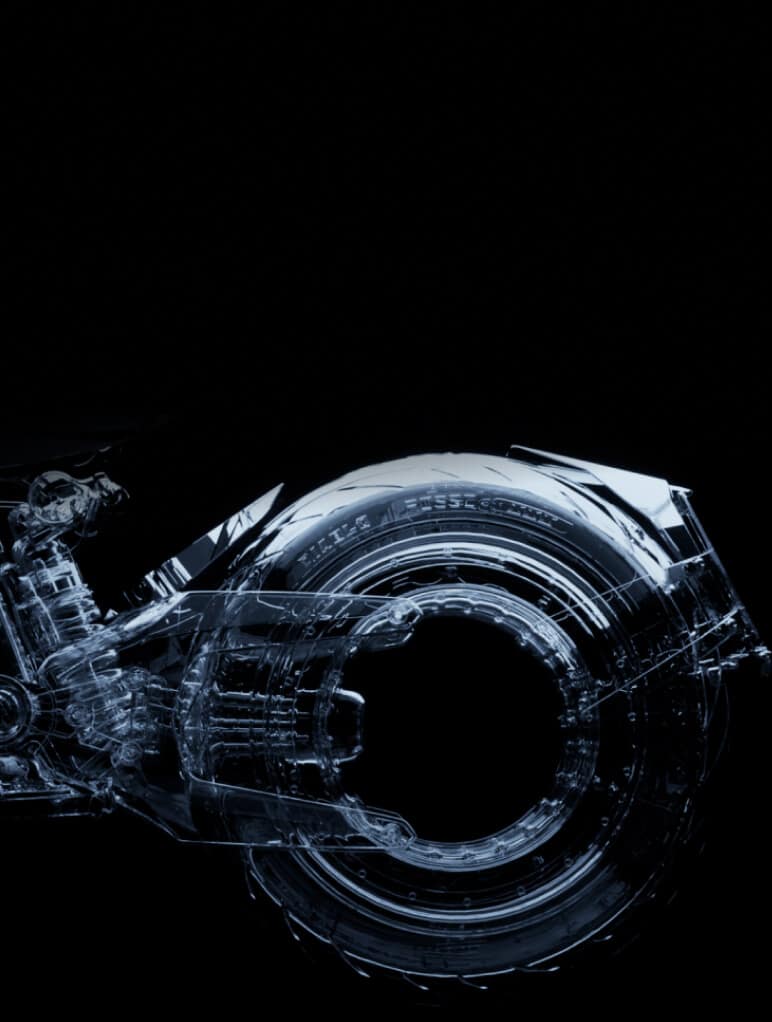

DIRECT DRIVE REIMAGINED

With the Donut Motor, traditional powertrains are a thing of the past.

Say Goodbye to Power Transmission

BENEFITS OF DIRECT DRIVE

The Donut Motor’s direct drive design eliminates the complexities of traditional powertrains, unlocking a range of powerful advantages.

Lighter & Compact

Direct drive minimizes unnecessary weight and takes up less space, making vehicles lighter, more agile, and allowing for increased design flexibility.

Cost Reduction

Reduces costs by eliminating unneccesary transmission components while reducing wear and extending lifespan.

Streamlined Design

A more straightforward design with fewer components reduces overall system complexity.

Low Maintenance

With fewer moving parts, direct drive requires significantly less maintenance. This ensures customer satisfaction with reliable, long-term performance.

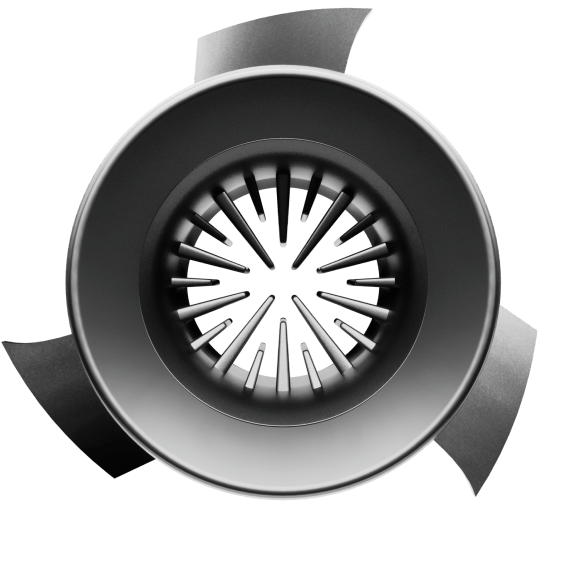

Maximum Efficiency

Enhances energy transfer efficiency for improved performance. This translates to greater power output and lower energy consumption while extending range.

Optimized Cooling

Generates less heat, reducing the need for additional cooling systems.

Revolutionary Precision

Unmatched control

Our direct drive technology enables control at a millisecond frequency, allowing for precision adjustments in real time. This level of responsiveness is far beyond what traditional systems can achieve. By delivering power directly to the wheels without intermediaries, our motor provides an unprecedented improvement in accuracy, stability, and traction control.

POWER & TorQUE

Delivering unmatched power and torque density for peak performance in any application.

A Revolution In Motion

Zero compromises. Maximum performance.

From hypercars to helicopters—the Donut Motor sets a new standard.

Next Gen Performance

The Donut Motor empowers EV and electric mobility manufacturers to build products with next-gen performance, without compromises.

Limitless Potential

Our motor has fully elastic performance specification. It can provide as much power and torque as required by your usecase – from hypercars to helicopters and trucks – without limitation.

Eliminating Unsprung Mass

With the world’s highest torque and power density, the Donut Motor reduces unsprung mass to an imperceptible level, all without sacrificing performance.

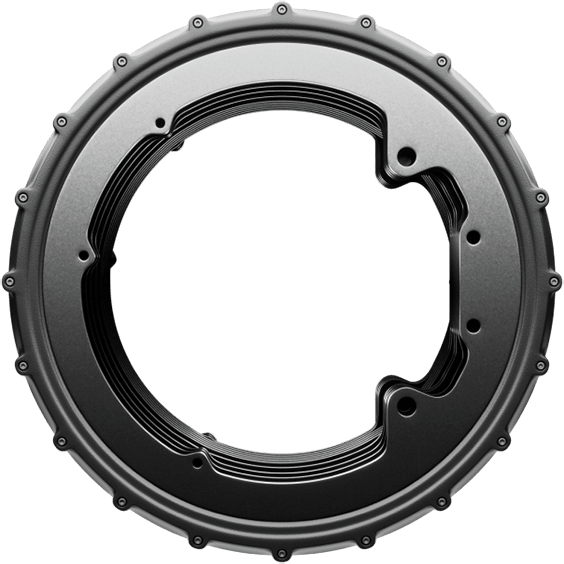

Redefining In-Wheel Motors

EXCEPTIONAL TORQue and Power density

Donut Lab’s next-generation in-wheel motors break free from past compromises, delivering both exceptional torque and power density in a compact, scalable design. Our technology enables higher performance and cost efficiency for a wide range of applications – without the trade-offs that once defined in-wheel motors.

SIMPLIFIED ARCHITECTURE

Redefining efficiency with fewer parts, less weight, and uncompromised performance.

Unlocking new possibilities

DESIGNED FOR SIMPLICITY

The Donut Platform redefines vehicle design, drastically lowering the threshold for creating new vehicles. By eliminating unnecessary moving parts, the architecture and engineering processes become significantly simpler and more streamlined.

With our solution, vehicles are not only lighter, but the cost of the powertrain is also reduced compared to traditional systems. This simplified design brings multiple benefits: decreased weight leads to greater efficiency, reduced manufacturing complexity minimizes costs, and fewer components translate to lower maintenance needs over the vehicle’s lifetime.

The result is a powerful, efficient, and elegant architecture that empowers innovation and makes cutting-edge vehicle development more accessible than ever before.