⇦

⇦

2025-10-17

Action shot:

I built a jogging buggy for our first daughter. I was considering buying a Thule, but fancied making something more lightweight/techy - my original plan was to sell them to other dumb weight-weenie parents, but certifying it would cost around £10k - maybe one day.

This post is a vague how-to with some lessons-learned. I'm not sure there's much value in anything more detailed.

Summer Mode

Winter Mode

CAD

I used onshape - I've used various bits of mech-eng CAD software in my life, onshape works in the browser and is seriously impressive. At time of writing, it's free if the designs are kept public and there's infinite YouTube videos on how to use it.

3D printing

I used 3DPRINTUK (Leyton based, quick, Ingerlandddd) and JCLPCB (slower, cheaper). The prints are all in MJF PA11-HP Nylon and seem plenty strong.

Tubes

The tubes are various diameters of 6081 Aluminium from metals4u. The forks are carbon, for added bling.

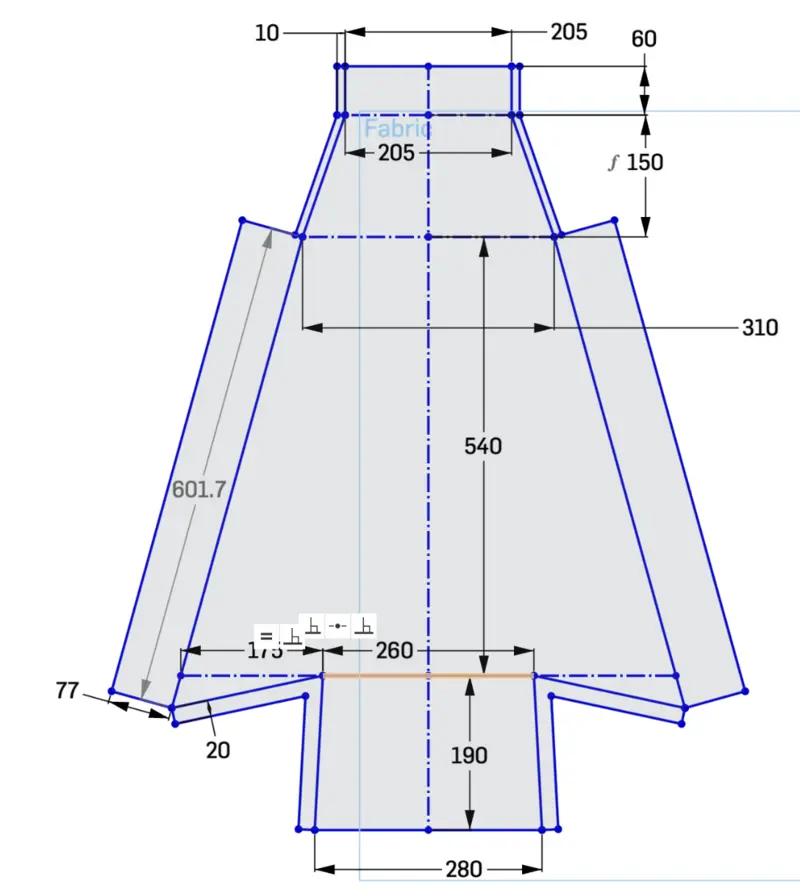

Plate

The inanimate carbon plate is precut 4mm carbon fibre from hyperdrivecarbon (they can cut to size on request), I drilled the holes with a normal metal drill bit.

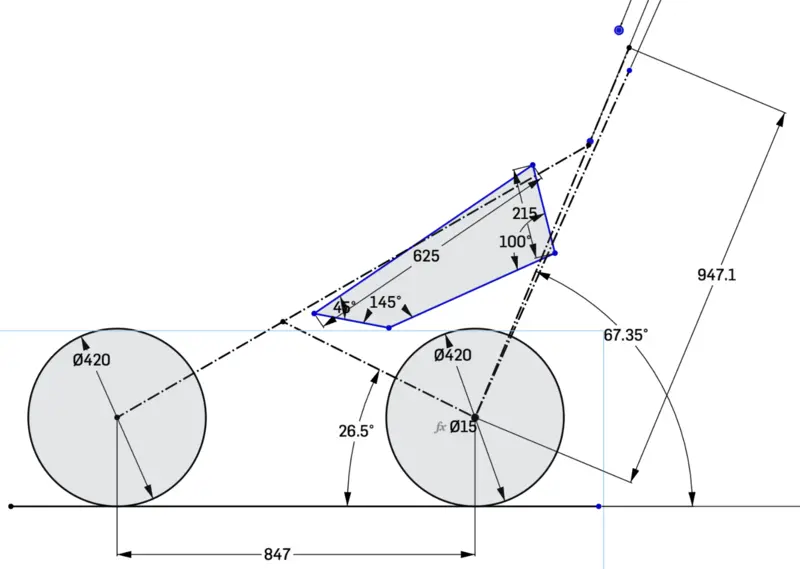

Geometry

So I didn't have to think too hard about geometry/balance, I drew over the side-on drawing of an existing buggy, then adjusted where I saw fit. The final frame looks like:

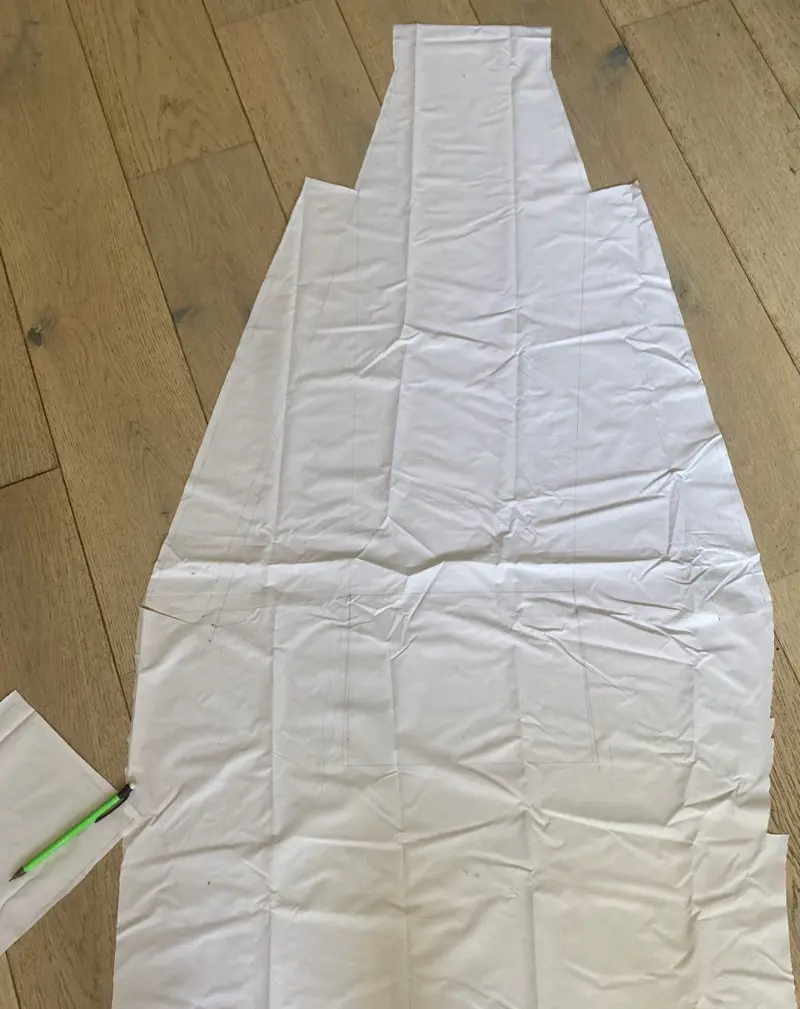

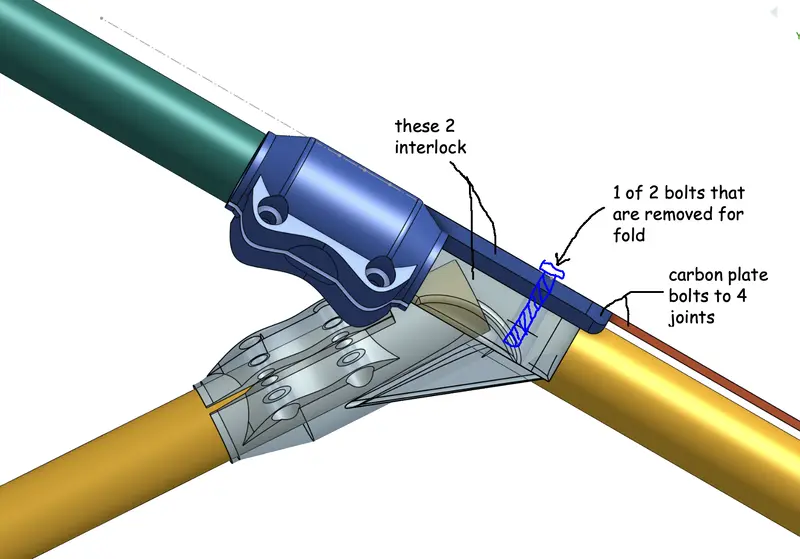

Sewing

I did a first "form finding" rough take of the fabric section in spare ripstop.

Then I measured from that for the final dimensions.

The final version is made from "12oz Heavy Duty Denier Fabric Cordura Canvas Fabric with PVC Backing for Sewing" and seems more than strong enough. It is supported by some plastic at the back - I ended up using some approx 3mm plastic sawed out of a large IKEA storage box.

Donor pram

The 5 point harness and fabric baby actually sits in are taken from a £20 donor buggy from the 90s. This included a zip-on winter sleeping bag bit that has been very useful, along with a canopy (this fitted on surprisingly easily) that has had some use in the rain:

Storage

I often buy bread half way round our run, so I added a small bag:

Folding

Undoing two bolts allows the whole thing to fold flat:

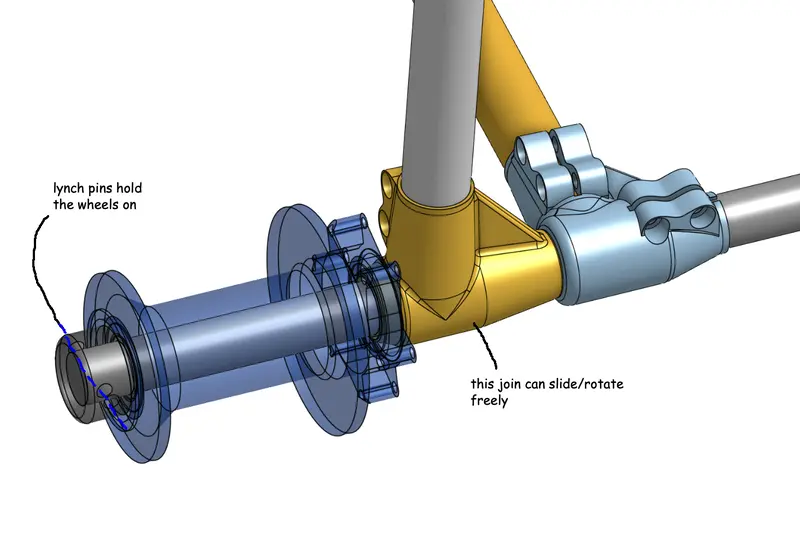

The rear wheels are attached with lynch pins so come off pretty easily.

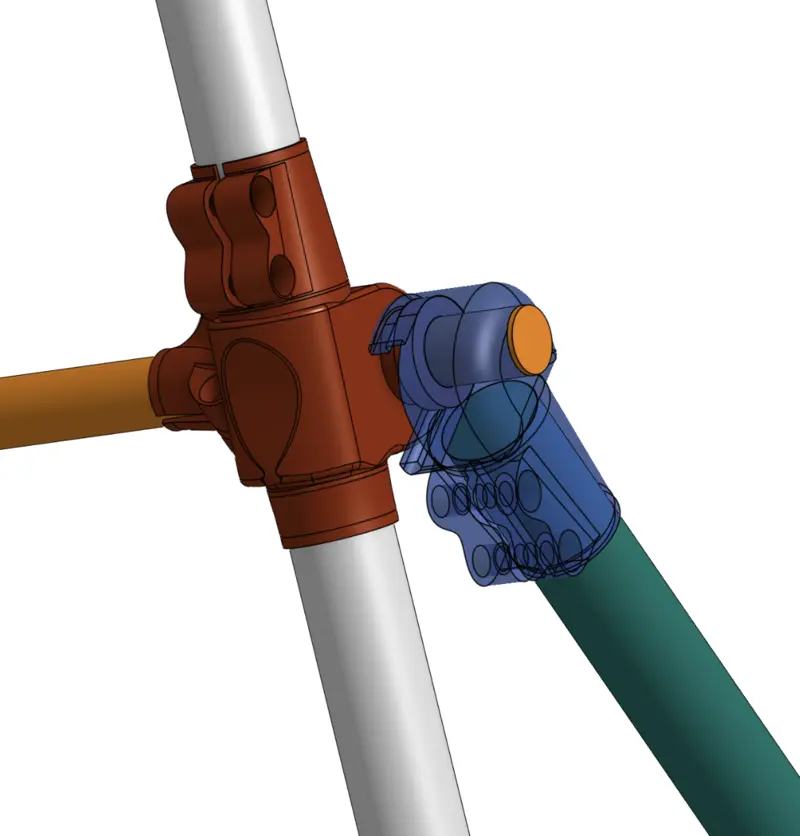

The nicest joint on the buggy is this one, there's two rotating/overlapping/slotted parts that are pretty neat.

Wheels

The wheels are AliExpress Brompton rims laced to MTB thru-axle hubs - I had to sand the tubes a bit to get them to slide on.

Lessons Learned

- Ultimately, I didn't trust the M4 threaded insert clamping mechanism for any of the serious joints, so I epoxied the tubes to the joints. In the future, I'd probably go straight to glue, although it's a bit stressful getting the distances/angles correct in one attempt. For anything where you still need adjustability, I'd go M5+ threaded inserts. On the front wheel, where the forces are high, the glue came loose (see below) - it would be worth researching different glues/approaches.

- Get some test joints printed to match your tubes before printing everything.

- I never fold it as it as it's a bit of a faff. There's definitely a nicer folding mechanism out there whilst keeping the design simple and light.

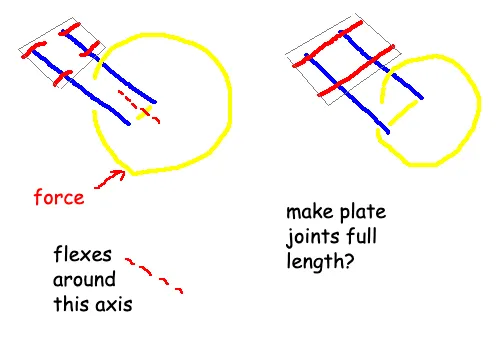

- The original carbon plate was 2mm - the forks would flex loads around the axis marked below, with the plate twisting in the parallel axis:

I just bought a thicker carbon plate, but it's pretty heavy and expensive, again, a better design is out there.

- Some of the new home 3D printers are cheap, compact and get good reviews, maybe PLA would be strong enough?

- The geometry seems good while running. The centre of mass could maybe be a tad further back to make steering easier at the expense of stability. Currently back-wheel-to-back-wheel is around 50cm and the seat is much lower than on a Thule to make up for the narrowness. I think you could go narrower still if you lowered the seat even more - I can't see much good reason for it to be high - narrow is good for city running.

- On the first run, it would steer slightly to the left. I loosened a couple of bolts and moved one fork like 2mm - this fixed it - being able to adjust the front wheel angle is pretty useful.

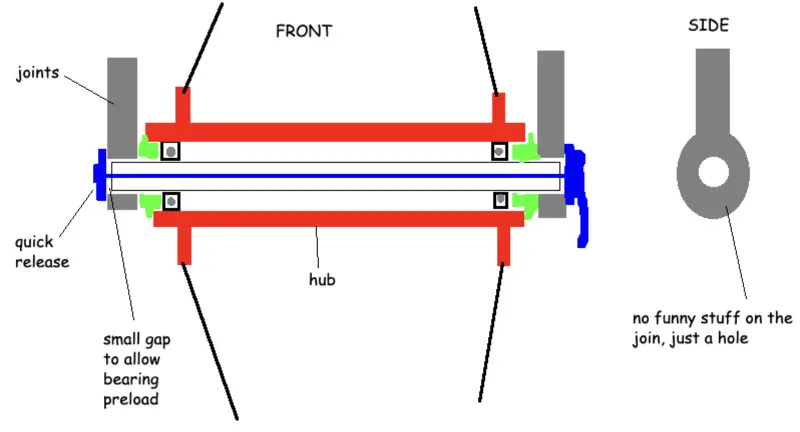

- It is possible adjust how tightly the wheels are attached, but there's still some play. Something more similar to a modern bicycle thru axle would be better, but tricky to manufacture at home.

After the first design came a bit loose, I added a quick release I had lying around - much stronger!

In the future, I would design it something like this:

- Some kevlar cord keeps the back rectangle shape from flexing too much. I think you could probably make this bit a triangle too and avoid this ugliness. If not, the cord could at least attach more neatly.

- The Brompton sized rims limit you to narrow tyres - maybe going 18 or even 20 inch would fix this. There is also a different 16 inch rim size designed for kids' bikes that that may have more options.

- I carry a reusable ziptie to attach a wheel to the frame as a parking brake - works great!

Cost

The cost was in the low hundreds of pounds. The 3D printing seems cheap as chips when you do your first test joint, but multiplied by 20 joints equals £150 or so. If you just want a buggy, buy a second hand Thule and resell it for near the same price. For what it's worth, I played with an Out n About Nipper in-person and the quality of the materials seemed wack.

Final take

We both do a 5km every morning and baby seems pretty happy - result! It was really fun doing the design and build, to the point where I'm tempted to do v2 for a friend. When the prices drop, I may attempt a 3D printed metal glued cargo bike frame à la Atherton Bikes.

If you want any more tips on building your own or want to join me and become the Cervélo of the buggy world - drop us an email (see home page).

Runner's eye view: