The Motors

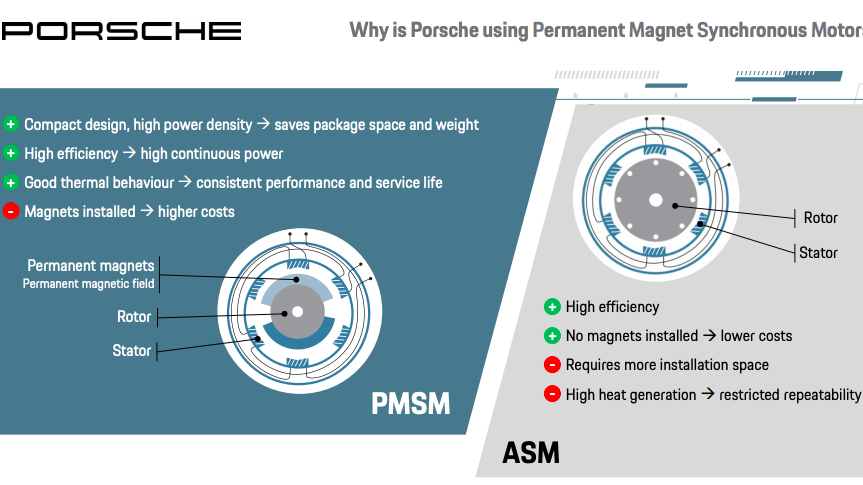

The Porsche Taycan is powered by two permanent magnetic synchronous electric motors, or PMSMs. Unlike AC induction motors used in some other electric vehicles like the Tesla Model S (though it and the Model 3 also use a permanent magnet motor), PMSMs utilize rare-earth magnets embedded into a rotor (which is what the output shaft is connected to) to create a permanent magnetic field. This spins in sync with a stator's (as shown in our look at a torn-down Model 3, a stator is just the "pipe"-shaped stationary bit of the electric motor consisting of a bunch of copper windings) rotating magnetic field, which is created by the sinusoidal AC input from the inverter, a device that turns DC power from the battery to AC power for the motor.

By contrast, an AC induction motors' rotor doesn't include rare-earth magnets, and instead consists of windings. As the inverter sends AC current to the stator and creates a rotating magnetic field, that magnetic field induces a current in the rotor windings, which creates a magnetic field. That rotor's magnetic field interacts with that of the stator, and the rotor spins, yielding mechanical torque. It's called "asynchronous" because the rotor lags behind the rotating magnetic field in the stator—a phenomenon called "slip."

The advantages of the permanent magnet design, Porsche mentions in the slide below, include high efficiency—particularly at the low and middle speed range—smaller size, and better cooling capability, though at a slightly elevated price point.

Even Elon Musk has talked about AC induction motors' cooling limitations, which Porsche powertrain manager Dr. Boyke Richter says are a result of the rotor requiring current, which creates heat that's difficult to remove.

"This limits the repeatability of the electric machine," he said. He also went on to mention how important size was, saying: "With the same power and torque level, the asynchronous machine is always a little bit bigger."

Porsche

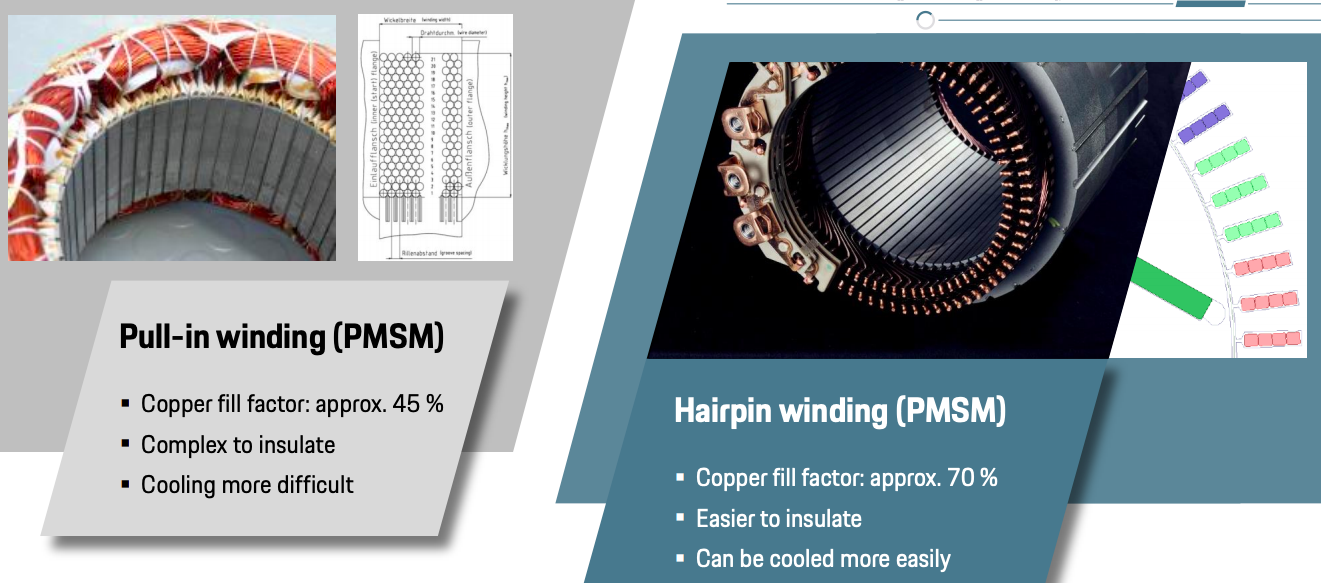

Porsche also mentioned the rectangular hairpin-style windings making up the stators—a setup we've seen before on the Chevy Bolt—as an advantage in that it can apparently fill the slots of the stator with fewer gaps than a traditional pull-in winding design.

The concept of fitting more copper in a given amount of space is quantified by a metric called a "copper fill factor," which Porsche says can be around 70 for a hairpin setup instead of 45 for the traditional "pull-in winding" stator setup.

Porsche

"By increasing the copper fill factor, you increase the performance," Richter told us. Not to mention the setup apparently allows for better cooling of the windings, with Richter saying it offers "better direct contact between the copper and the stator pack, meaning you get the heat that is generated inside the copper by the current flowing through it better out of the machine, and again... better cooling possibility and more repeatable performance."

Porsche

The Transmissions

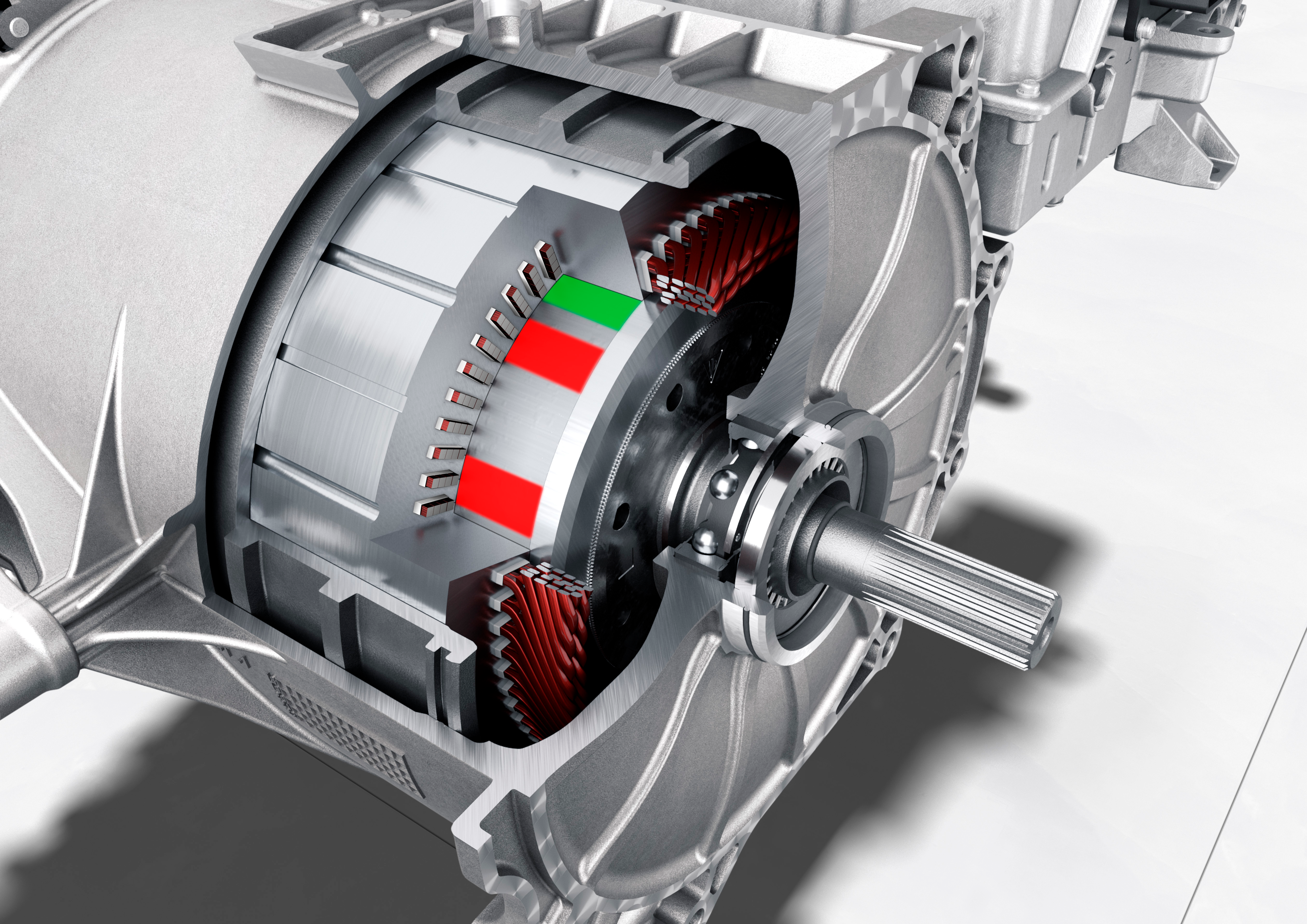

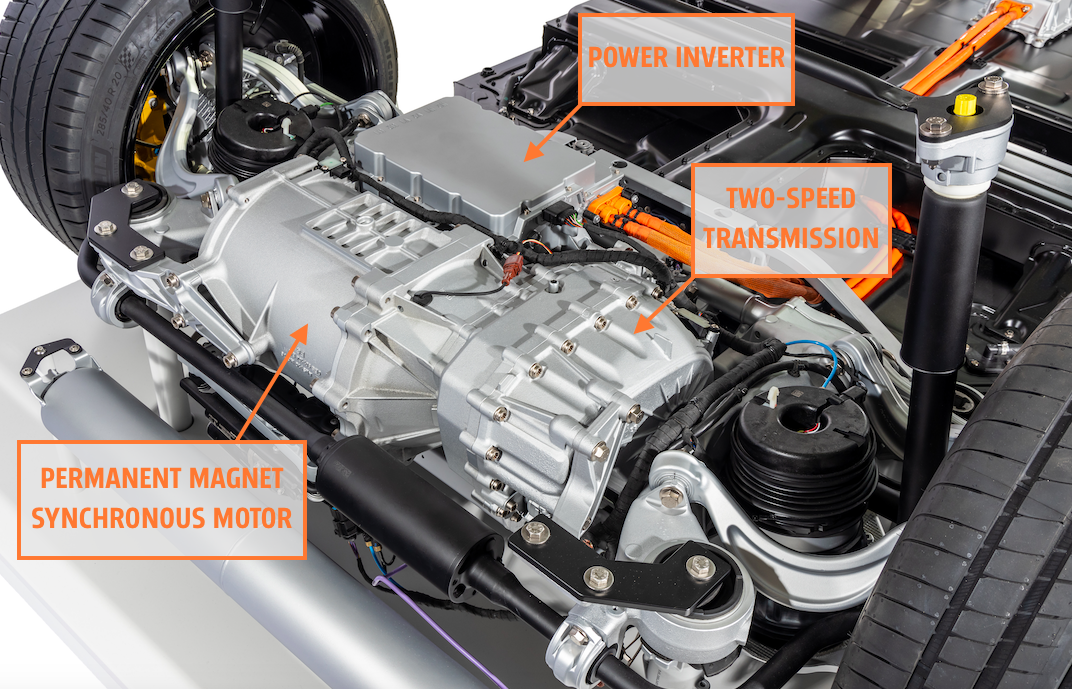

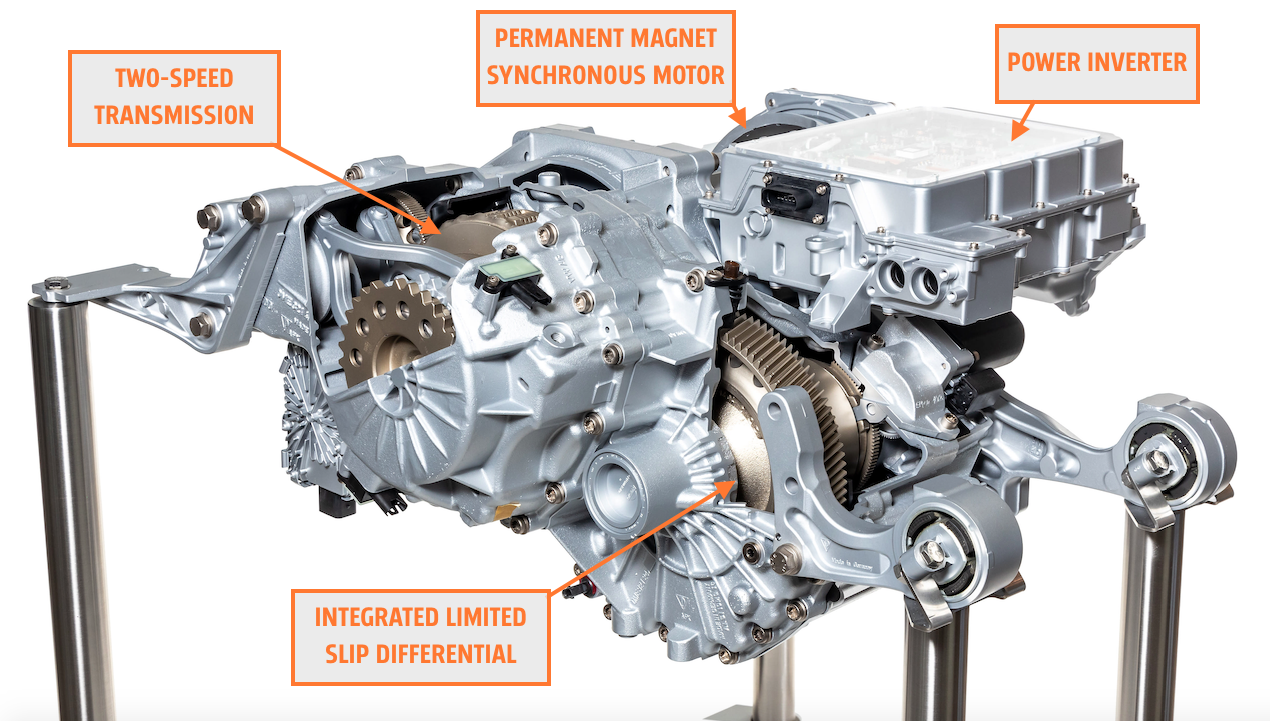

Of the two motors in the all-wheel drive Porsche Taycan, the one in the rear is more powerful. It makes 449 horsepower and 406 lb-ft of torque (or 450 lb-ft during launch with the Turbo S), and sits parallel to and aft of the axle centerline, sending power forward through a Porsche-designed and manufactured two-speed gearbox. That gearbox has a first gear ratio of roughly 16:1 and a second gear ratio of 8.05:1.

Porsche

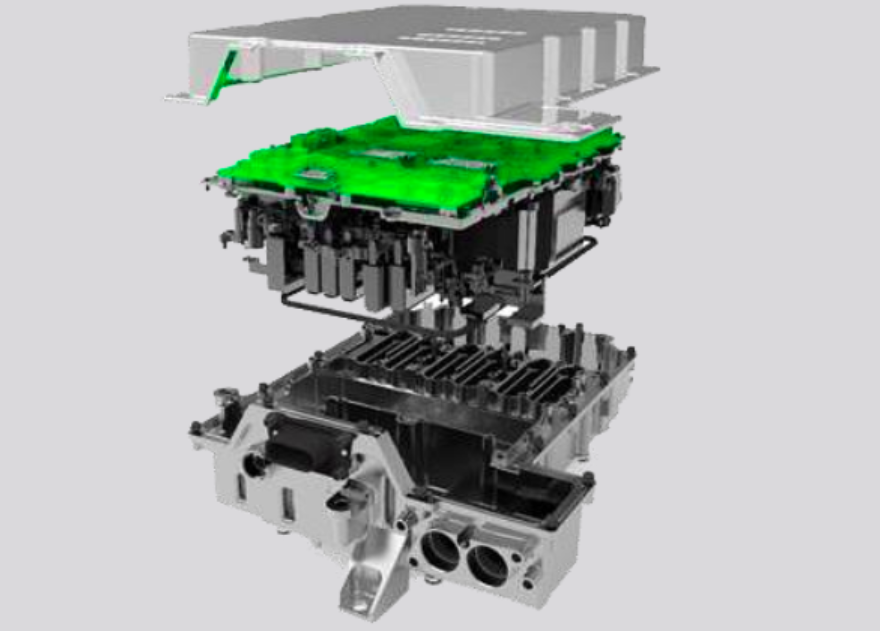

The "rear axle module," as Porsche calls it, consists of the motor, transmission, and power inverter, the latter of which, as previously mentioned, takes DC current from the battery and converts it to AC current for the motor. That entire module, whose casing appears to be made largely of cast aluminum (Update: Porsche says: "We will not divulge the exact materials, but cast aluminum is present in the powertrain."), weighs about 375 pounds, Porsche claims.

The transmission, which also houses a clutch-based electronic limited slip differential (I guess you could call this gearbox a transaxle, then), is a fascinating unit, as I know of no other mainstream electric vehicle in the U.S. that currently offers a two-speed gearbox.

Porsche says it does in order to improve efficiency, and also to help optimize both low-speed acceleration and top-end speed—pretty much exactly the benefits that auto supplier ZF claims of its new two-speed EV transmission.

Here's another angle of the rear axle module:

Porsche

The transmission has a torque capacity of 406 lb-ft, which is oddly less than the max output of the rear motor during launch (I'm trying to clarify this with Porsche). It and the entire rear module was designed to be as compact as possible and to sit flat to allow for ample trunk space. It is set up such that the motor is at the rear, and its output shaft enters a transmission, which stretches forward to a differential whose output is in line with the rear axle. Mounted just in front of the motor and above and towards the passenger's side of the diff is the 600 amp power inverter box.

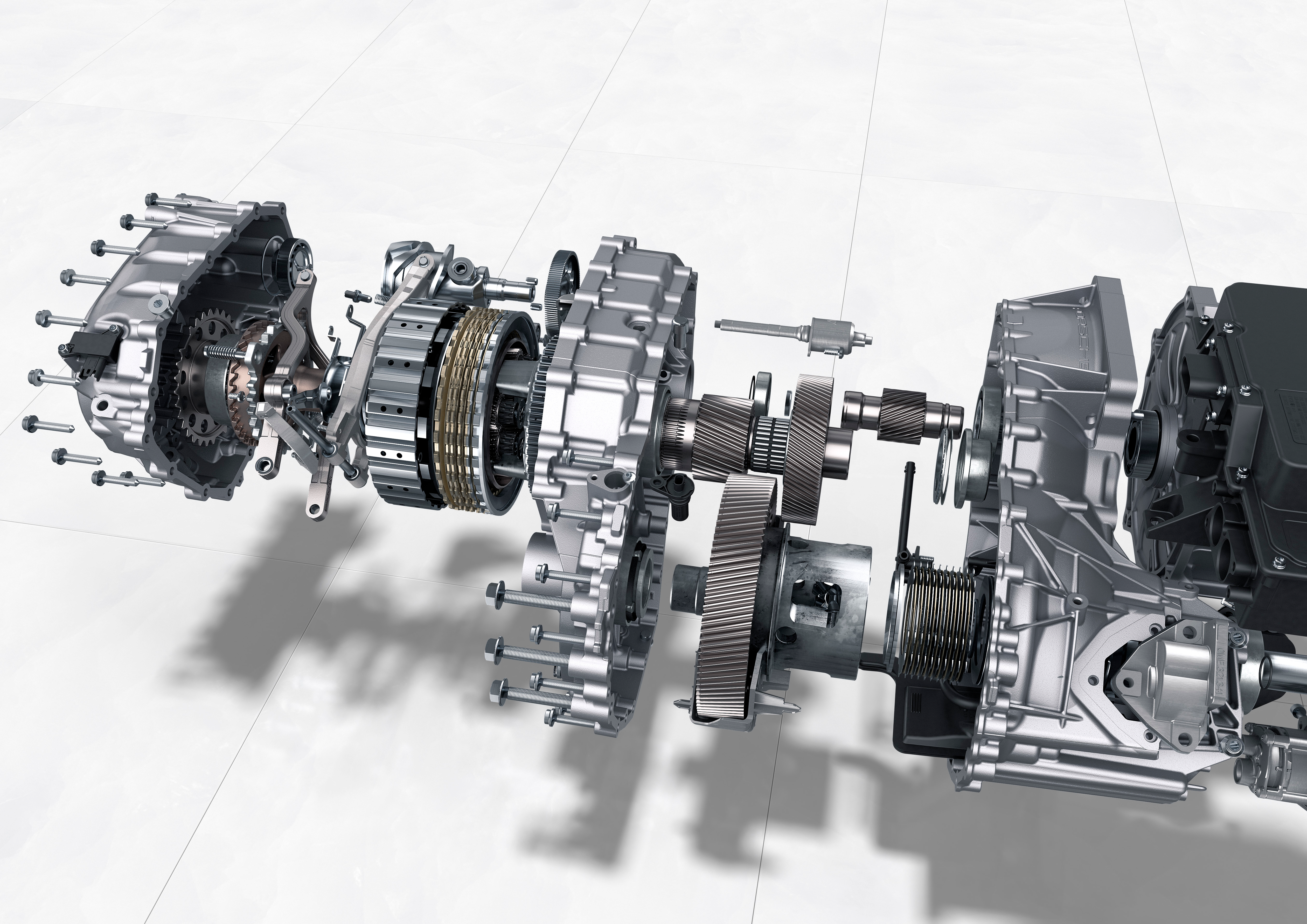

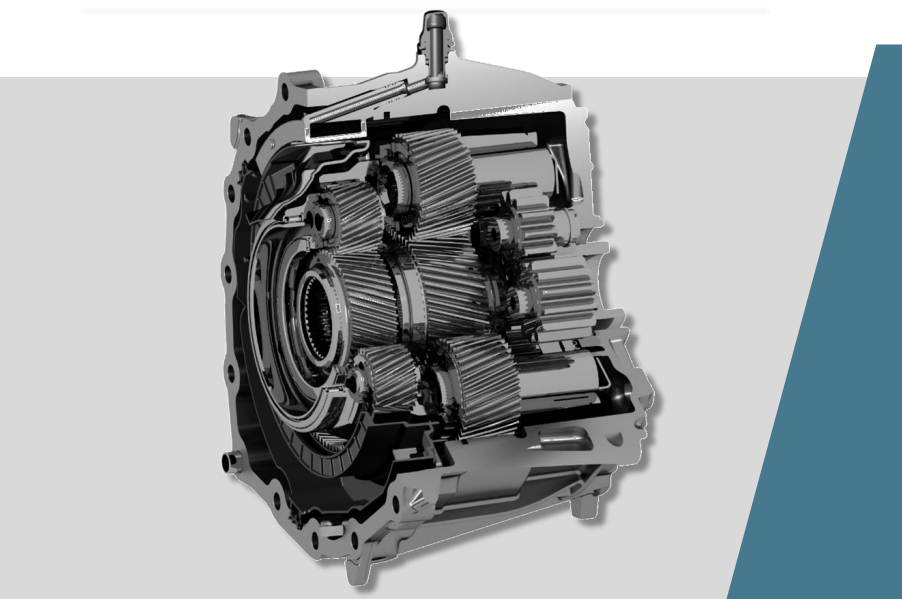

Here's a look inside the transaxle case:

Porsche

"We integrated only one actuator in this transmission for all different stages—first gear, second gear, neutral, reverse, and park," Dr. Boyke Richter told journalists.

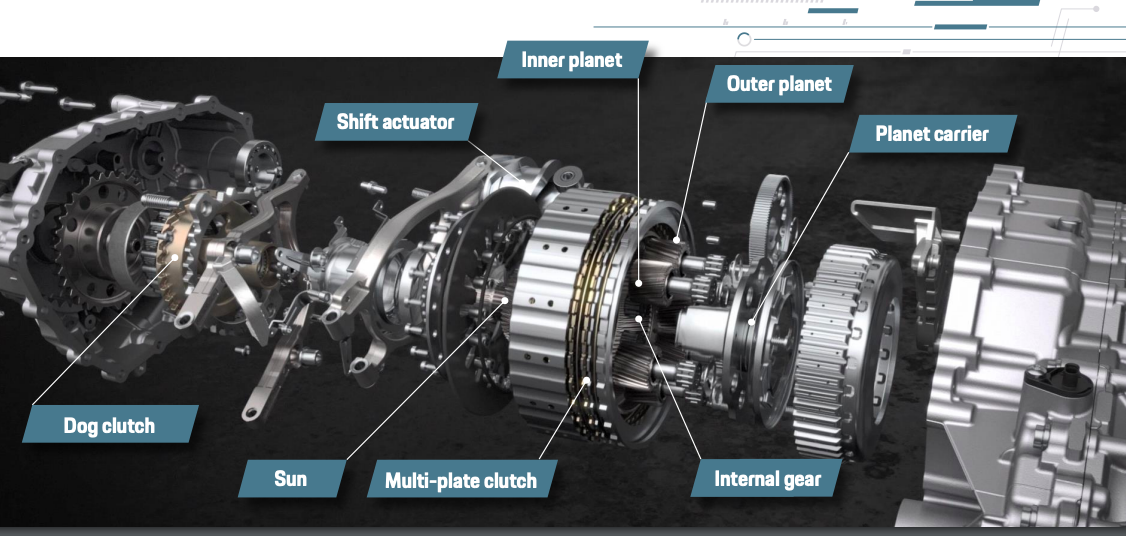

Referring to the main shaft of the two-speed trans, Boyke explained the innards. "On the upper part, you see the actuator, it actuates two levers that are connected with a dog clutch and a multiplate clutch. Inside the multiplate clutch there's a planetary gearset that ensures the ratio for the first gear," he told us.

Porsche

In first gear, he explained, the multiplate clutch is open and the dog clutch is closed, with the planetary gearset yielding the 16-ish-to-one ratio. "When shifting to second gear, the dog clutch opens, and the multiplate clutch is closing, blocking the planetary gearset, and by this blocking, we spare the losses of this gearset, and we're able to increase the efficiency...[in] second gear," he continued.

Porsche

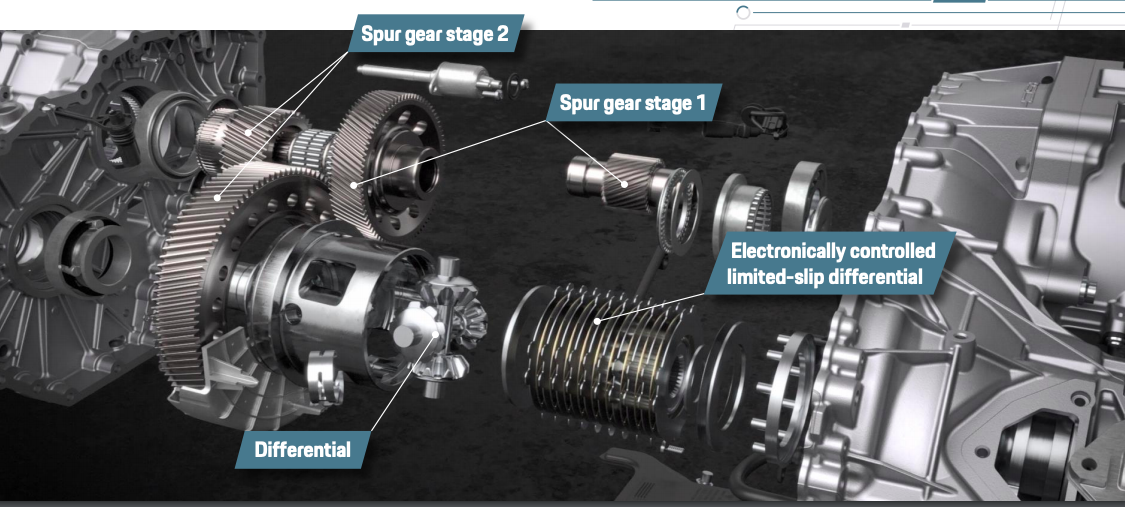

"On the output shaft, we have the differential itself," an electronically controlled limited slip diff, which is "the same component as you already know from [Porsche's] other vehicles," he went on.

We've seen other manufacturers like BMW (in a development car, admittedly) use two electric motors in the rear, avoiding a differential entirely to achieve more instant torque vectoring capability, but—for packaging reasons, and likely cost, I'd suspect—Porsche decided for a single motor and a conventional limited slip differential.

Porsche

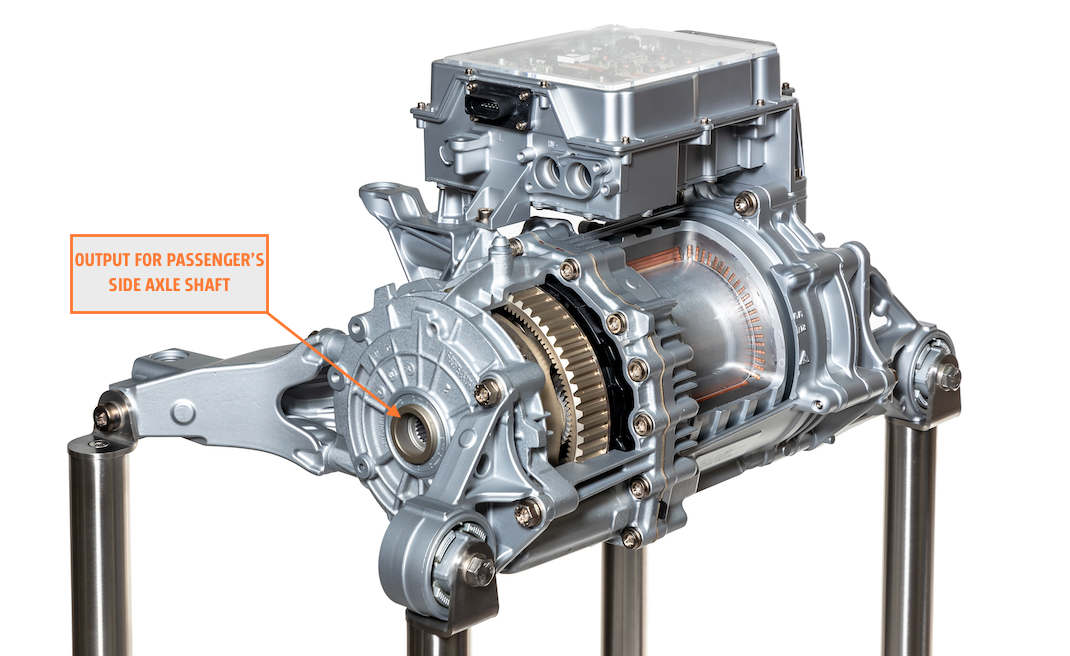

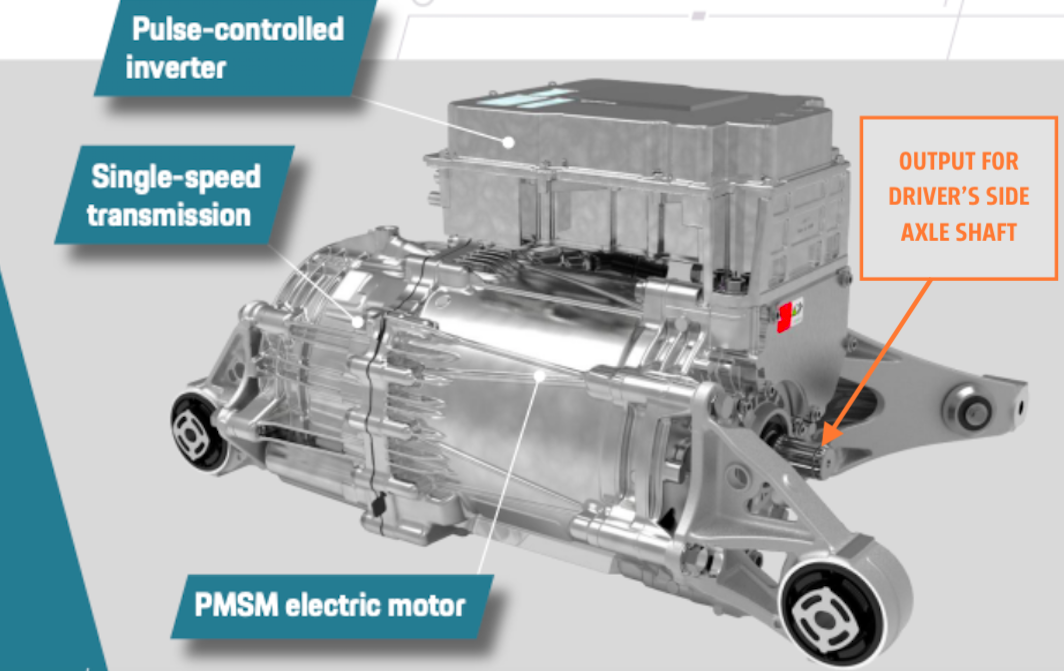

The single-speed front drive module is similarly fascinating in that, like on the Jaguar I-Pace, it incorporates a coaxial transmission design. The transmission bolts directly to the end of the motor, which is located right on the axle centerline, between the front wheels. In fact, one of the front CV axle shafts actually passes through the center of the motor's rotor to hook into the transmission.

The image above shows the passenger's side output location, and the picture below shows the driver's side output shaft:

Porsche

Also shown is the inverter, which, for the front motor, comes in two flavors: 300 amp peak output (190 amp continuous) and 600 amp (380 amp continuous), with the latter coming in the Turbo S and enabling a maximum output of 255 horsepower and 325 lb-ft of torque during short launch events (and 295 lb-ft for longer durations). The standard Turbo model's front motor, with its 300 amp inverter, pumps out 238 horsepower and a maximum of 221 lb-ft.

The two inverters, which yield 168 pound and 157 pound total weights for the front axle module, save cost by sharing quite a few components, Porsche says. It's not clear if the 600 amp rear inverter is the same as the 600 amp optional front inverter, but I bet it is. (Update: Porsche says it's different).

Porsche

The weight of the coaxial transmission, which features two planetary gear sets and offers an 8.05 reduction (the same as second gear on the rear motor), is much lower than that, at just 35 pounds dry. It has a 332 lb-ft torque capacity when accelerating and a 221 lb-ft torque capacity when sending torque the other direction when recuperating. This regenerative braking, Porsche says, happens mostly up front, but also at the rear motor, with maximum power recuperation at 265 kW as measured at the battery and maximum longitudinal deceleration of 0.39 G.

Porsche says the transmission is passively cooled, using the water jacket around the electric motor.

Porsche

Shifting That Two-Speed Transmission

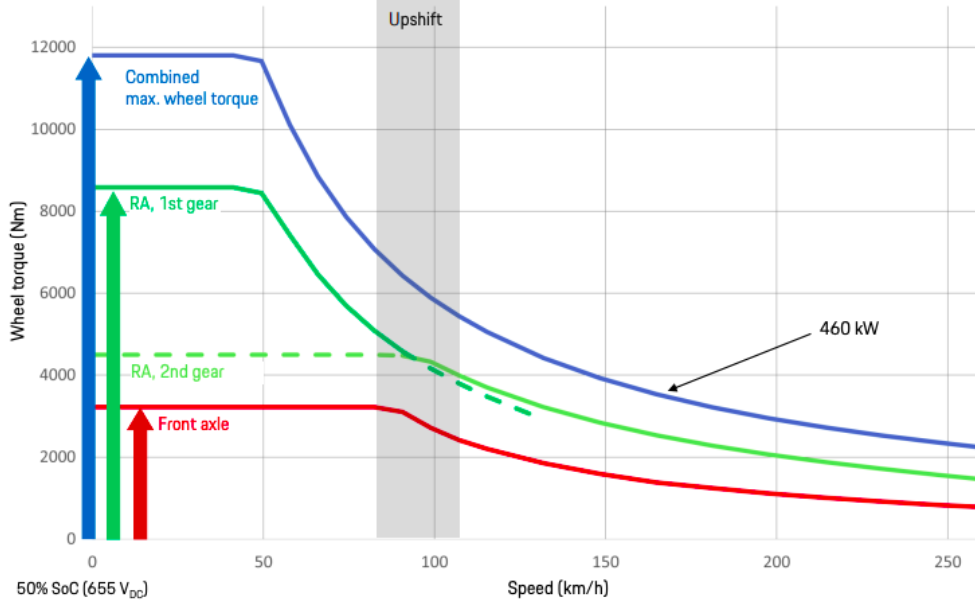

What's most interesting about all of this is how Porsche sets up the shifts in the rear two-speed transmission. To demonstrate the advantage of the two speed, Porsche showed curves of wheel torque (which is directly related to vehicle acceleration) versus vehicle speed for each motor/gear ratio combination—see below. (These look like typical EV torque curves).

As shown, at about 100 km/h, or 62 mph, first gear runs out of steam, and the motor isn't able to send much torque to the rear wheels (and at 81 mph, the motor hits its 16,000 RPM max speed), which hurts vehicle acceleration.

It's at the point around 62 mph vehicle speed that the Taycan upshifts, yielding the solid green curve you see below, allowing for more torque at the wheels, and thus more acceleration to a higher top speed.

Porsche

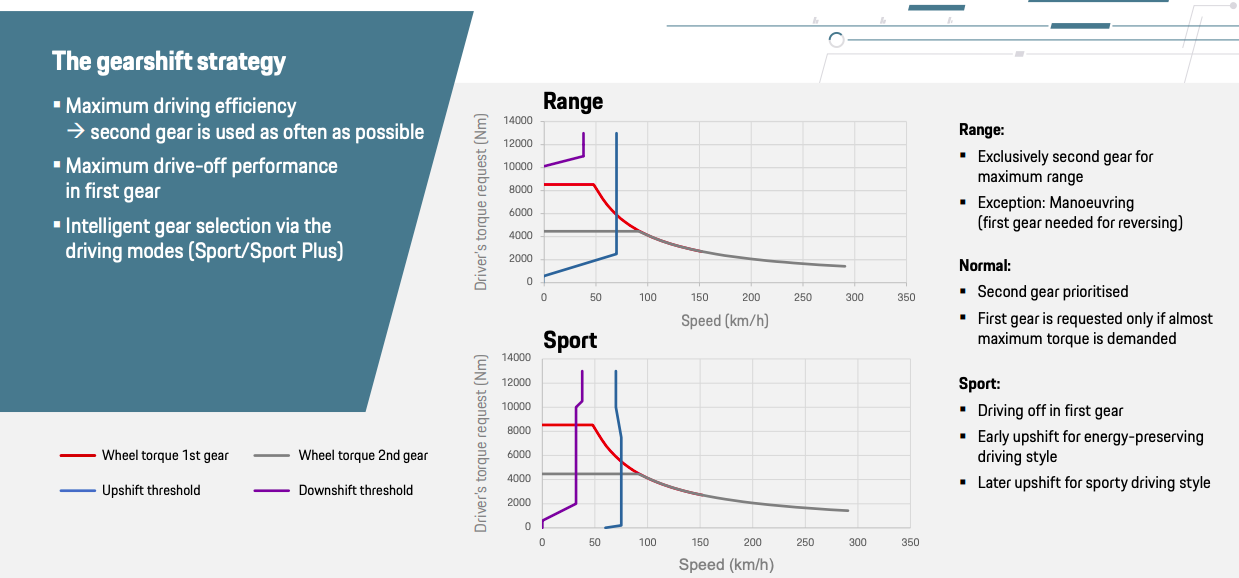

The shift strategy changes based on the drive mode, which hold gears differently. Range and Normal mode, Porsche told us, prioritize second gear to optimize efficiency. It is worth noting that, in some cases, the Taycan can actually run completely in front-wheel drive and decouple the rear transmission to reduce losses.

Though Porsche considered it, the front transmission has no clutch to allow for decoupling, so the motor is always mechanically connected to the wheels. This, if I understood it correctly, was done for packaging and reasons related to vehicle control, and with the understanding that the small motor and planetary gearbox don't yield too high losses.

Back to the modes: Porsche says "Range" only goes into first for reversing functions (this is due to mechanical constraints, as I understand it) and "Normal" downshifts during heavy pedal inputs. "Sport" mode, on the other hand, holds first gear as long as possible to maximize acceleration. Porsche even provided some shift maps below:

Porsche

The map here doesn't look that different from that of a traditional transmission, with the blue and purple lines representing when the vehicle would upshift or downshift, respectively. If I'm reading this right, looking at the "Range" plot, you can see that at only low vehicle speeds and extremely high torque requests (in other words, the driver is deep on the throttle while traveling slowly), you'll cross the purple line and downshift to first.

Then, even if you keep your pedal buried, the car will shift to second around 75 km/h. Otherwise, in "range" mode, you'll be in second always. (In the slide above, Porsche says "Range" stays exclusively in second gear, so perhaps I'm misreading the shift map. (Update: Porsche confirmed that even "Range" mode will downshift to first).

The "Sport" map shows that even at low vehicle speeds and low torque requests (your foot is barely on the pedal), you're in first gear, and you won't upshift until you hit roughly 75 km/h. This shifting, in case you're wondering, happens roughly as quickly as a dual-clutch transmission shift.

"We are not faster [than a dual clutch]," Richter said, "because we have a large ratio spread between first and second gear," and therefore transmission needs time to synchronize. Still, the good news is that, according to him, there's "no traction interruption during shifting."