The Linear Tape Open (LTO) consortium has reacted to higher capacity disk drives and SSDs with a 33 percent LTO-10 raw capacity upgrade to 40 TB and a target downgrade for the LTO-14 generation of 365 TB from the prior 576 TB.

LTO tape is used for archiving and the consortium of HPE, IBM, and Quantum is responsible for the LTO generational roadmap. The current generation is LTO-10 and it was originally specified to have a 36 TB raw capacity. In the event, sole LTO tape drive supplier IBM and tape-ribbon manufacturers Fujifilm and Sony were only able to achieve 30 TB. As disk drive capacity has passed 32 TB and SSD capacity is now at the 120 TB-plus level, tape cartridge capacity has been lagging behind.

Now the LTO trio have responded and upgraded LTO-10’s capacity to 40 TB, partially enabled by a new aramid-based tape ribbon film substrate material. This is thinner and smoother than the prior polyethylene naphthalate (PEN) film.

Stephen Bacon, VP, Data Protection Solutions Product Management, HPE, said: “AI has turned archives into strategic assets. The new 40 TB LTO-10 cartridge will help enterprise-class organizations – across healthcare, financial services, media, research, manufacturing, the public sector, and beyond – consolidate petabytes efficiently, strengthen cyber resiliency with true offline air-gapping, and keep long-term retention affordable and sustainable.”

Aramid, short for aromatic polyamide, refers to artificial fibers made from organic polymers which form a rigid structure of long-chain molecules and have a high strength-to-weight ratio. They were devised in the 1960s and used in DuPont’s Kevlar products to produce bullet-resistant vests for example.

The new aramid ribbon material enables longer tape lengths in a standard LTO Ultrium cartridge form factor, thus increasing tape cartridge capacity.

The LTO consortium says that, once 40 TB LTO-10 cartridges are available, customers will be able to choose between the two different LTO-10 media types based upon their individual cost and capacity requirements, allowing greater flexibility in media deployment.

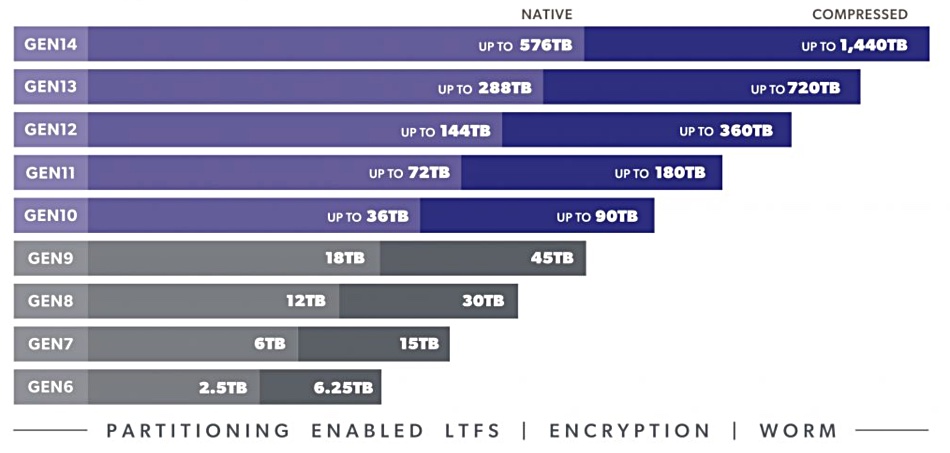

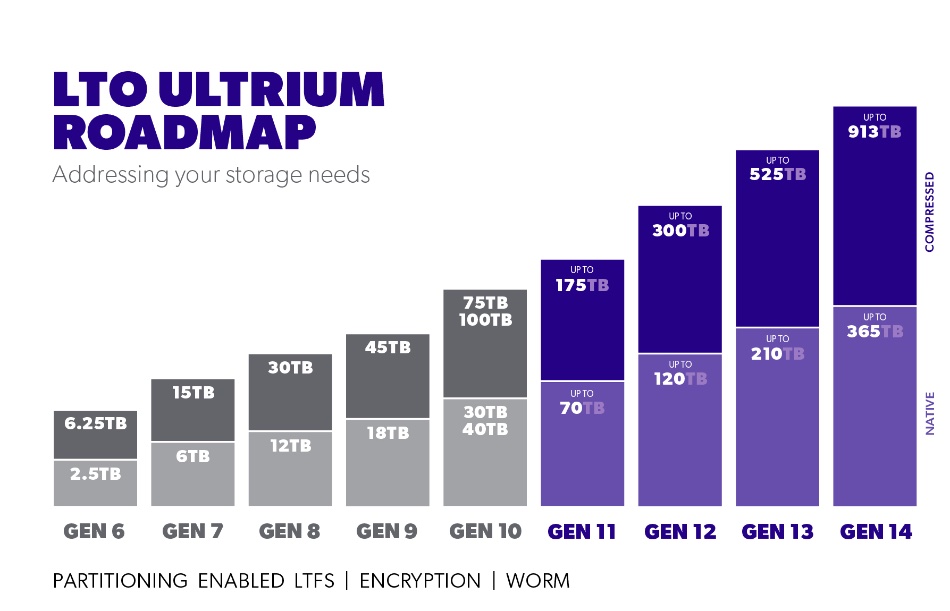

The consortium is also re-evaluating its roadmap. It has set itself a target of 913 TB compressed capacity for the LTO-14 generation, meaning up to 365 TB raw. This is a reduction from the previous roadmap, set in 2022, as a chart indicates:

The new roadmap chart:

In terms of raw capacity and the “up to” numbers:

- LTO-11 moves from 72 TB to 70 TB – 2.8 percent lower

- LTO-12 moves from 144 TB to 120 TB – 16.7 percent lower

- LTO-13 moves from 288 TB to 210 TB – 27.1 percent lower

- LTO-14 moves from 576 TB to 365 TB – 36.6 percent lower

These are substantial capacity reductions, with LTO-14 dropping well below its previous 1.44 PB compressed capacity level to 0.9 PB.

This roadmap and the LTO-14 capacity level will preserve, we are told, exabyte-scale growth paths for tape libraries. The consortium says that this revised roadmap is tightly aligned with anticipated storage requirements in the coming years and gives the technology space to grow should users require it. The new capacity points will prioritize reliability and value in terms of cost per terabyte. Consortium members want to ensure LTO tape will remain a practical and affordable storage choice for every type of business or workload.

An LTO consortium spokesperson told us: “The updated roadmap projects approximately 75 percent capacity growth per generation, based on native capacities. This approach maintains a consistent proportional increase from Gen 11 onward, ensuring that the jump from Gen 13 to Gen 14 follows the same pattern. The 913TB figure reflects the 2.5x gain when calculating compressed capacity for Gen 14. Overall, the revised roadmap delivers a balanced combination of density, reliability, performance, and cost efficiency, while providing a smooth innovation curve with steady capacity growth across generations.”

We think we are seeing tape technology limitations in action here and the reduced capacities will provide headroom for tape replacement technologies such as Cerabyte’s ceramic-on-glass tablets.

Bootnote

The primary manufacturer of aramid film used as a substrate for magnetic recording media manufacturer is Toray Films, a Japanese corporation, making the Mictron brand product. Tape-based magnetic recording media suppliers, such as Fujifilm and Sony, could use the aramid substrate as the base layer for their tape ribbons, applying, for example, a strontium-doped barium ferrite layer to it. The LTO consortium has not identified its aramid-based LTO-10 tape ribbon manufacturers.