From prototype parts to production runs

-

Instant quoting with free design analysis

-

100+ combinations of materials & surface finishes

-

Quality prototypes and end-use parts in as fast as 1 day

Get an instant quote All uploads are secure and confidential

Join thousands of companies using Protolabs Network

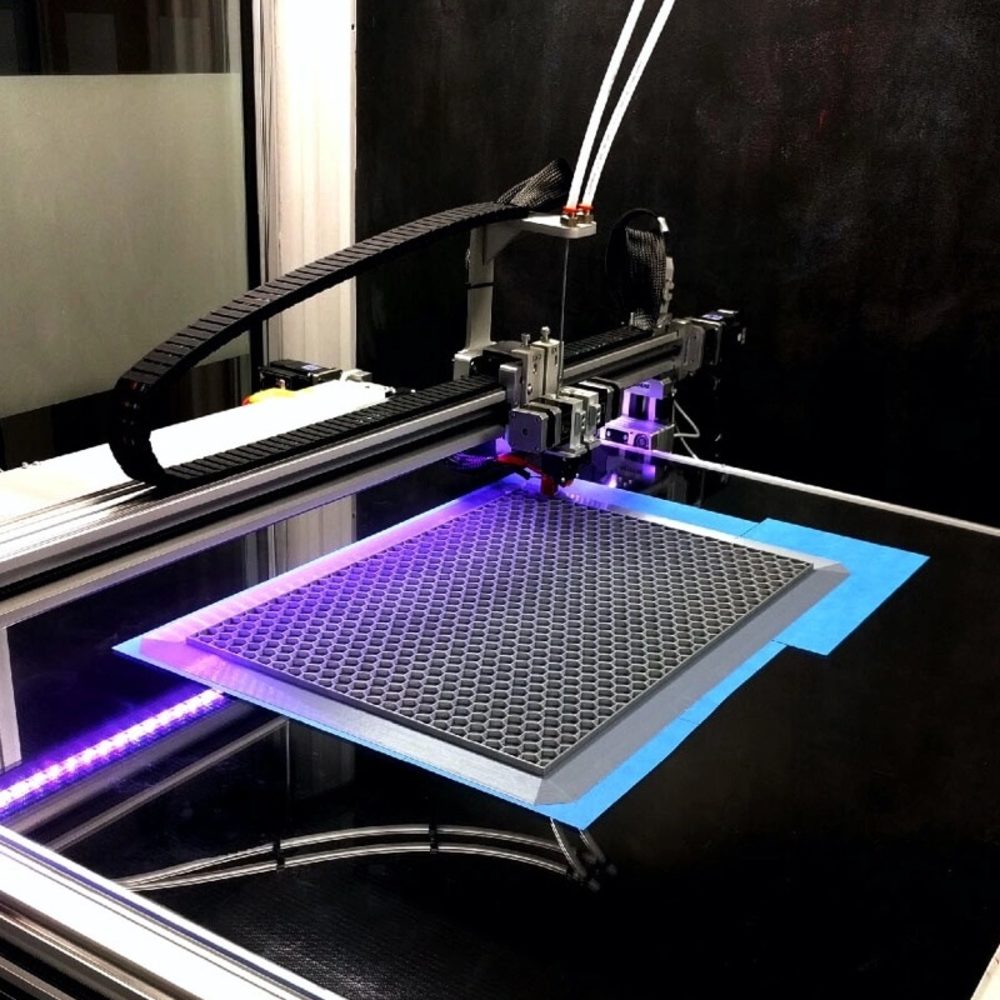

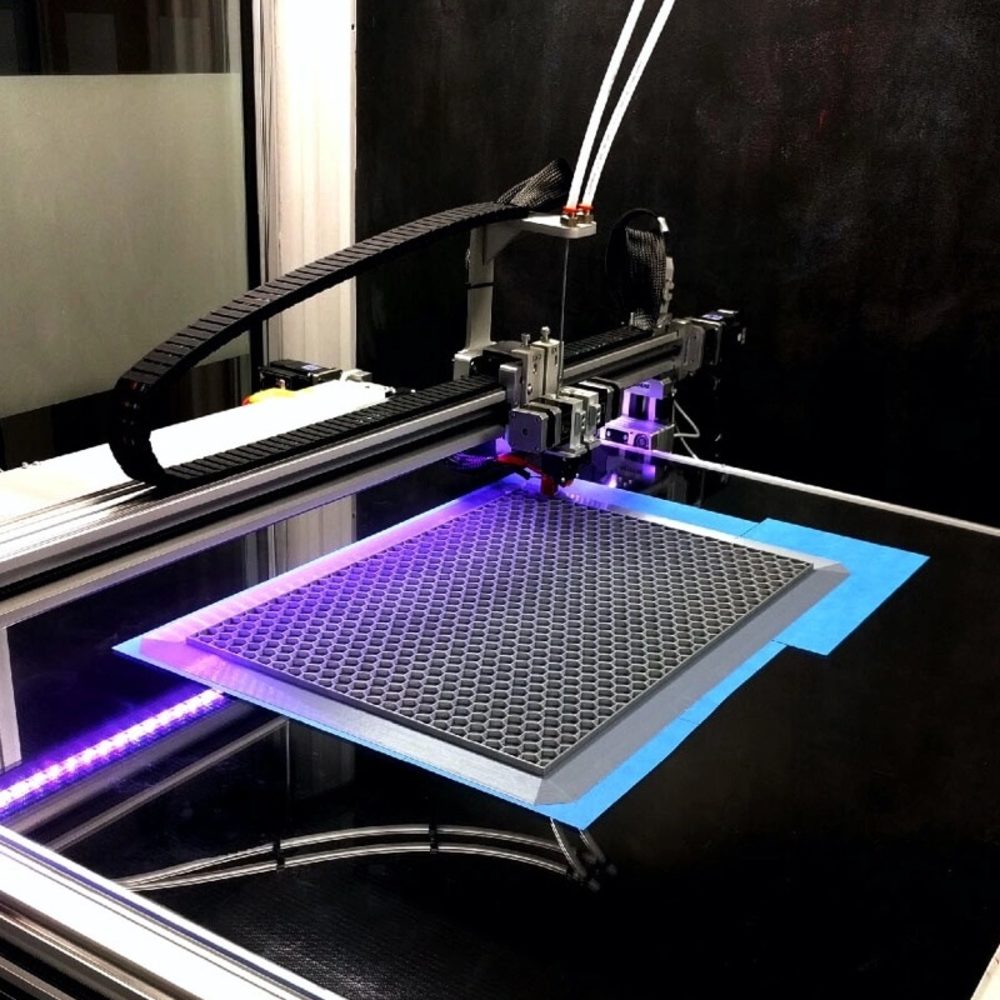

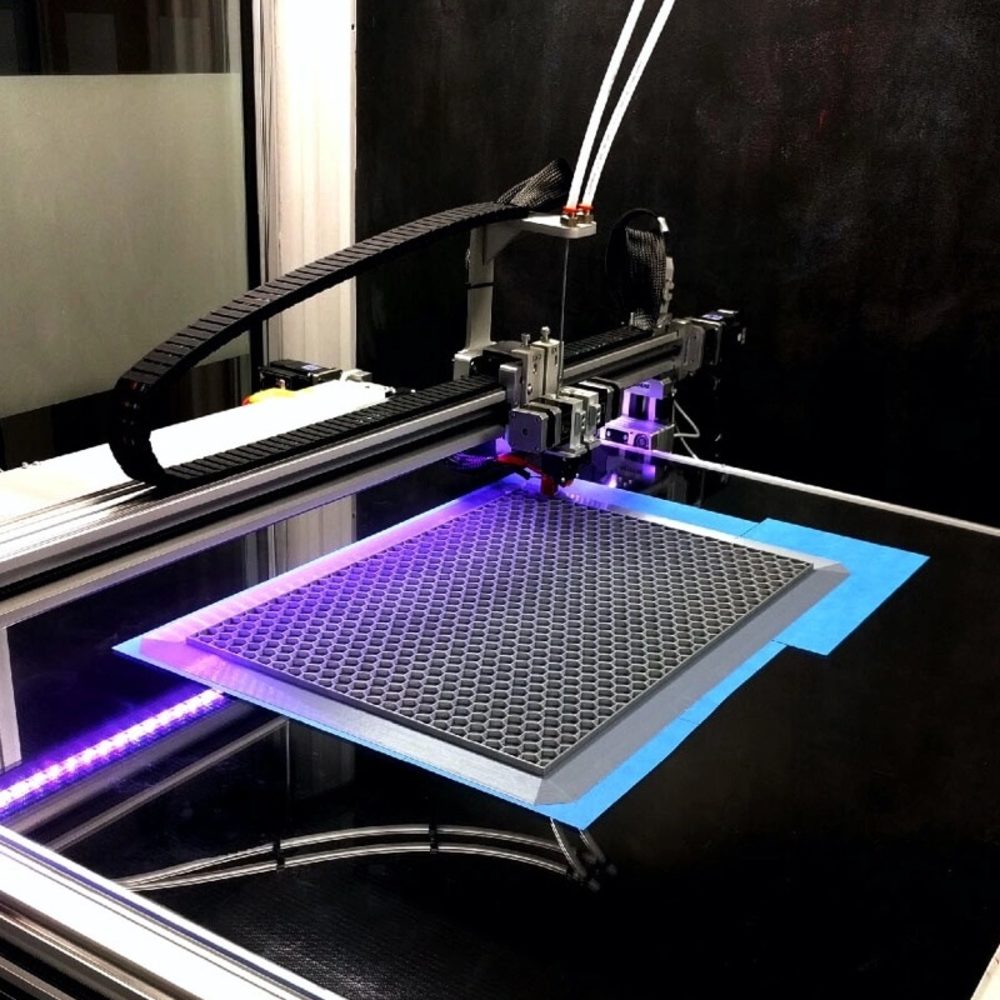

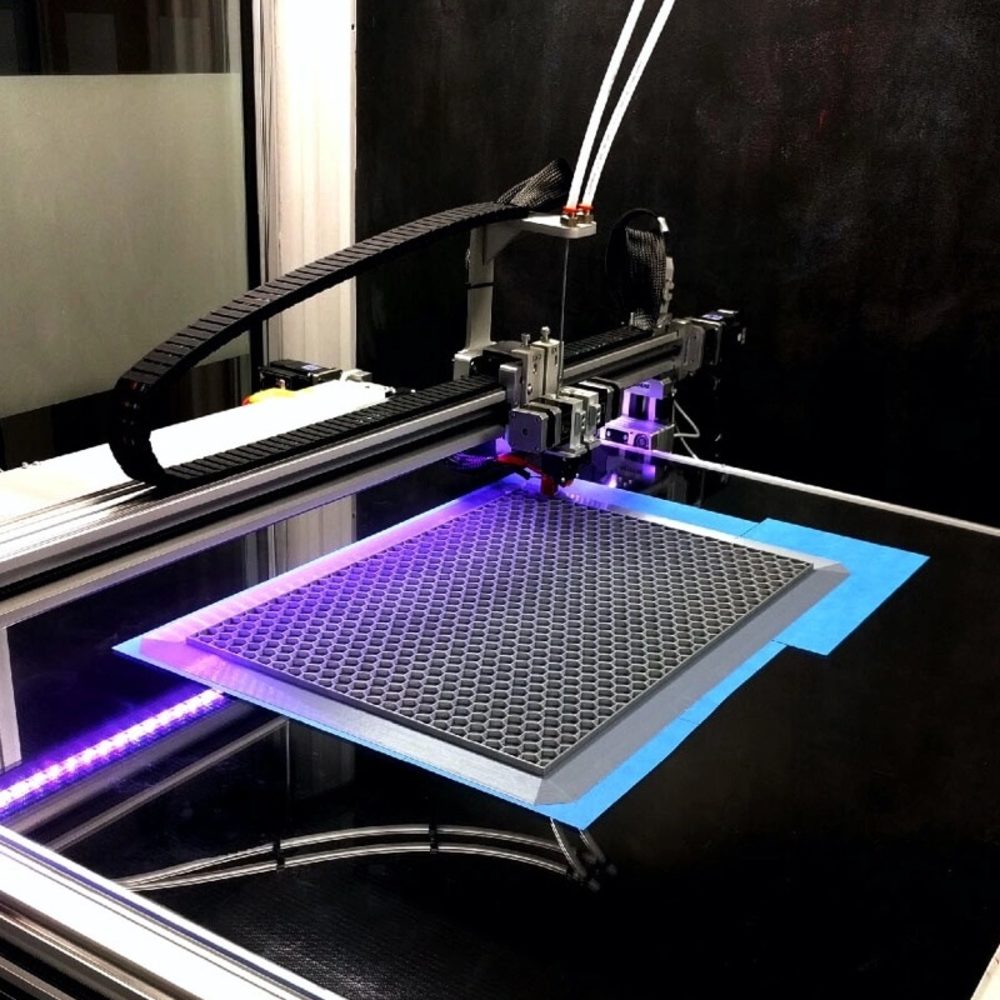

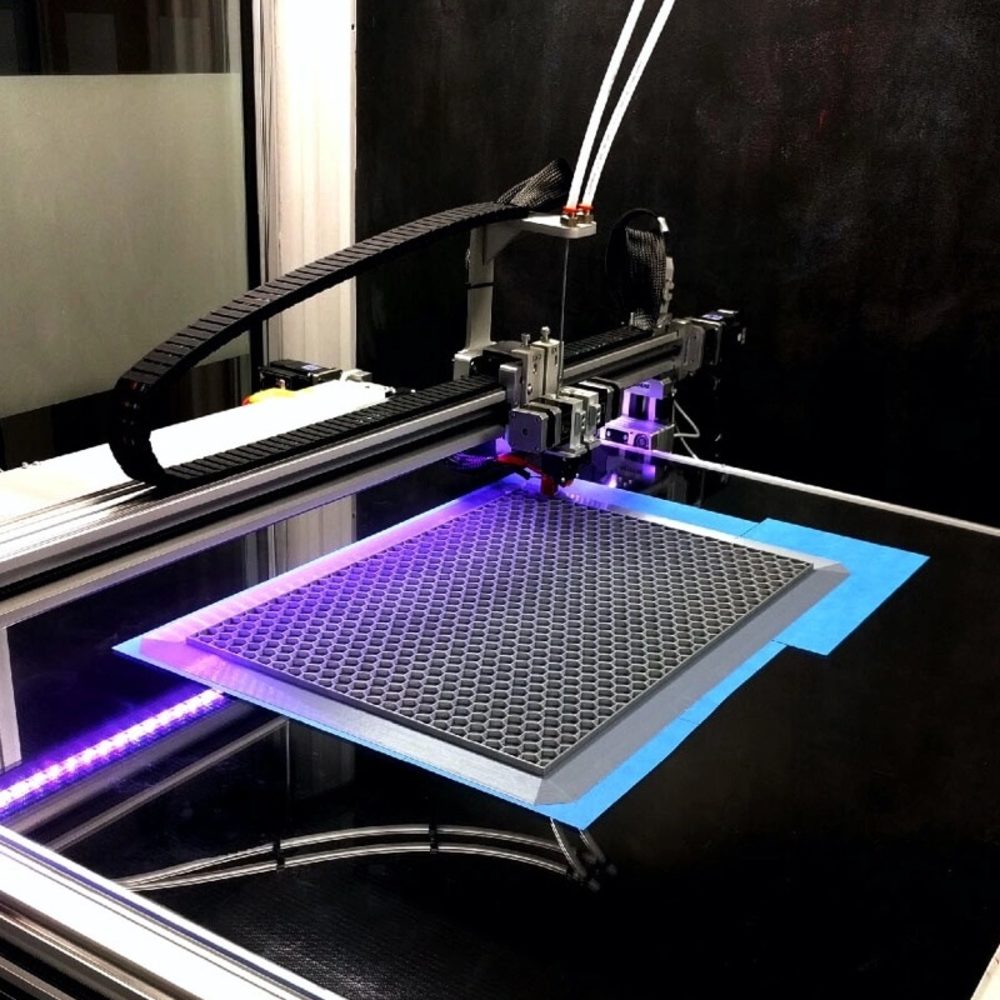

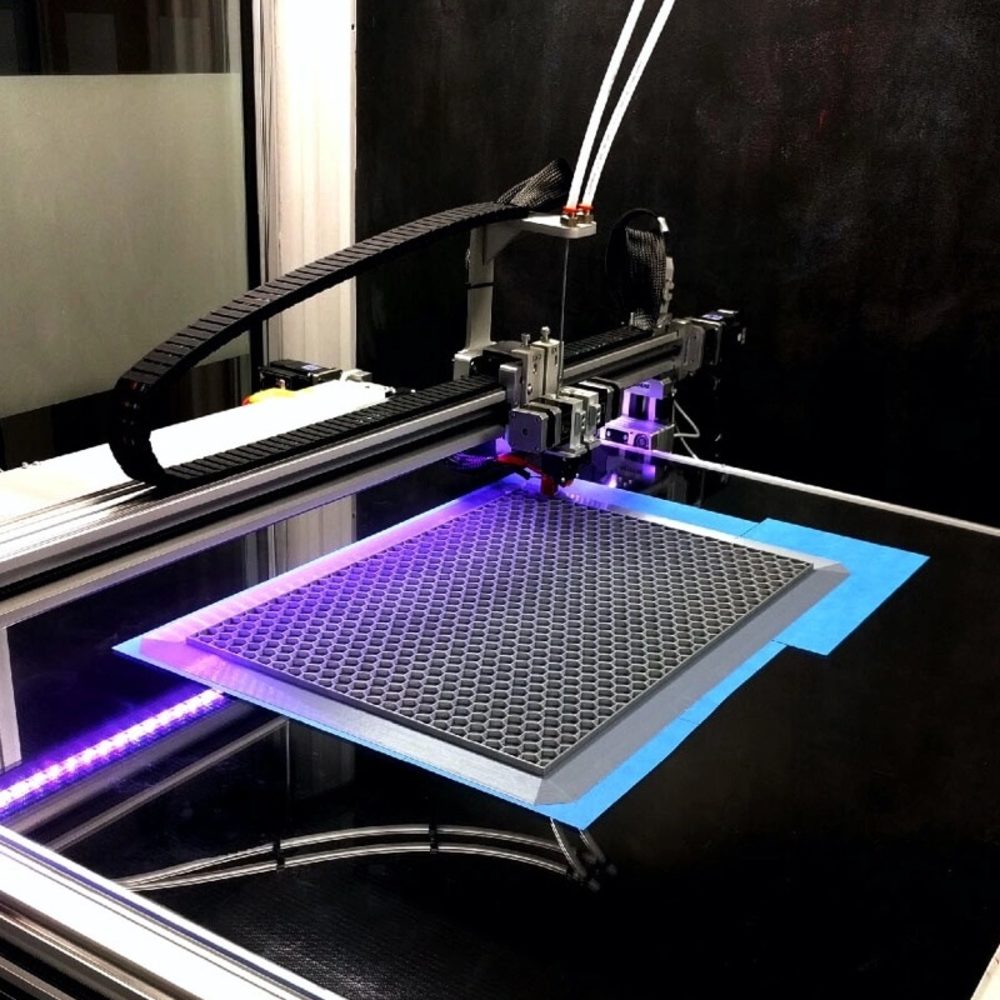

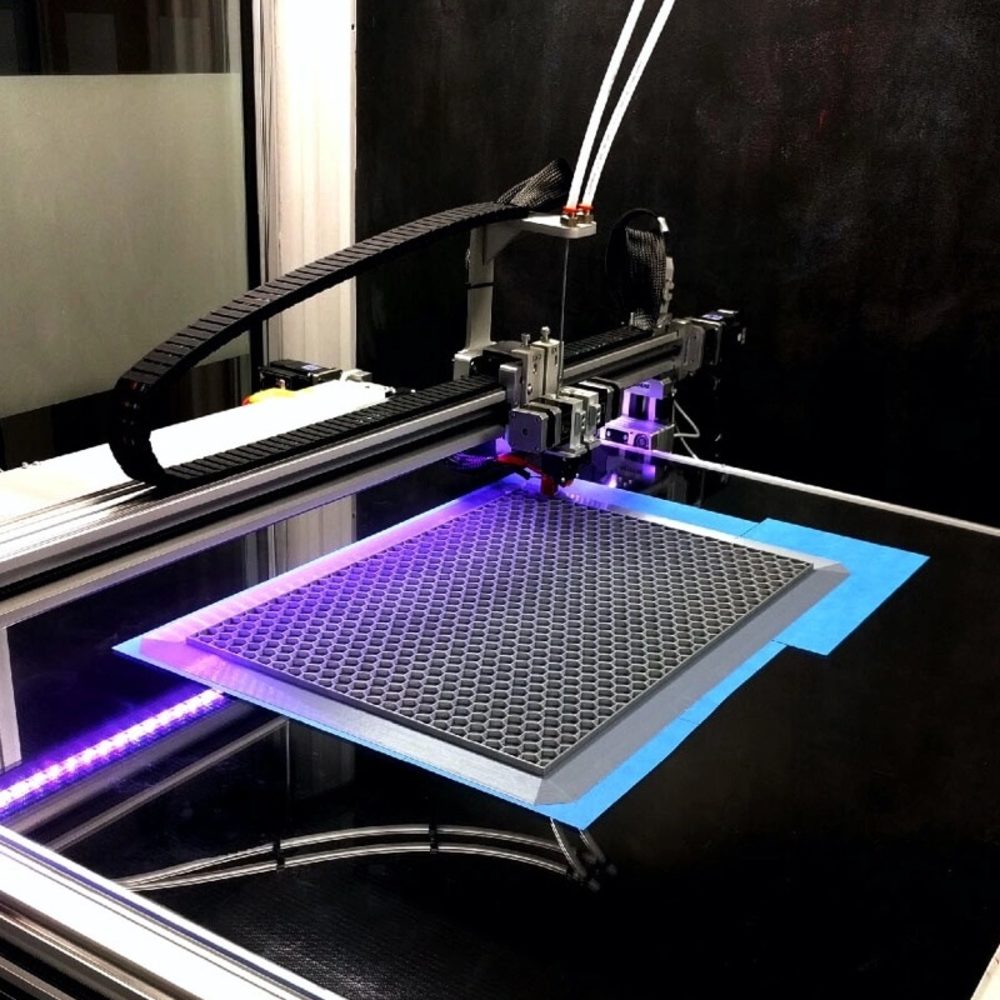

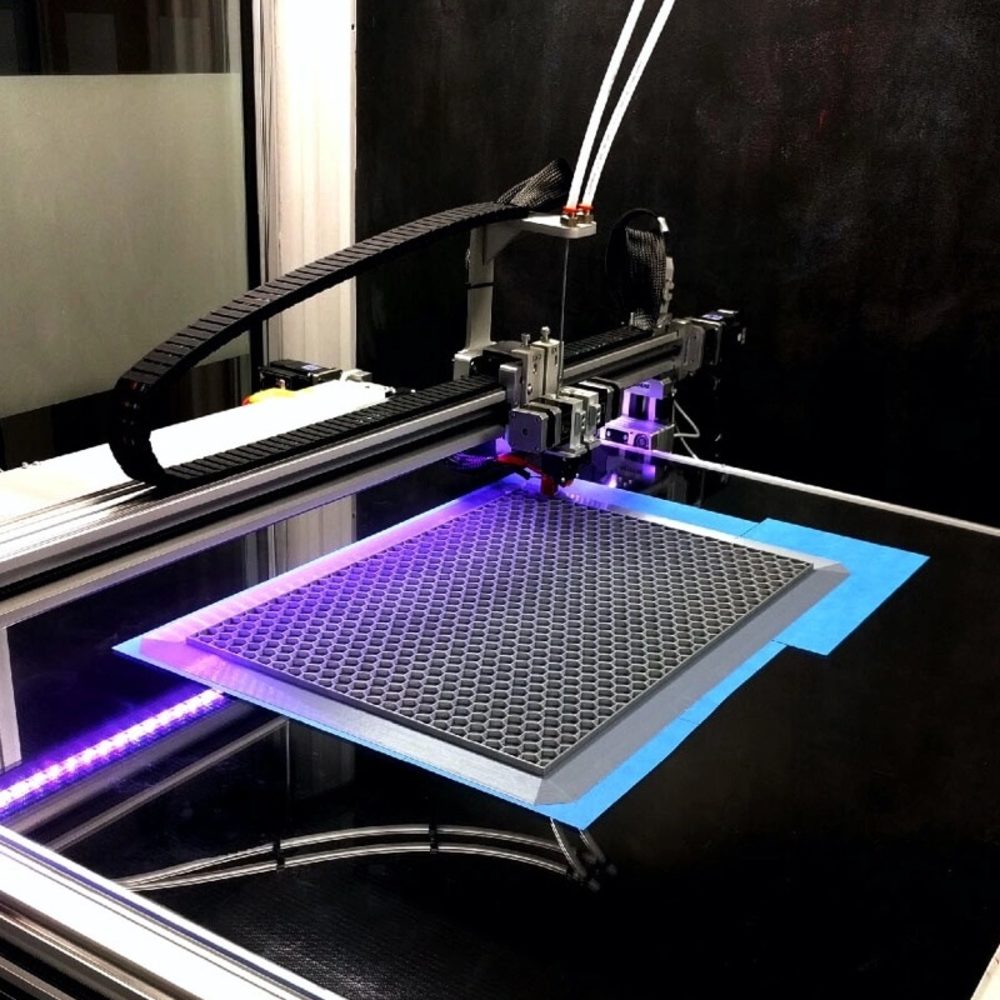

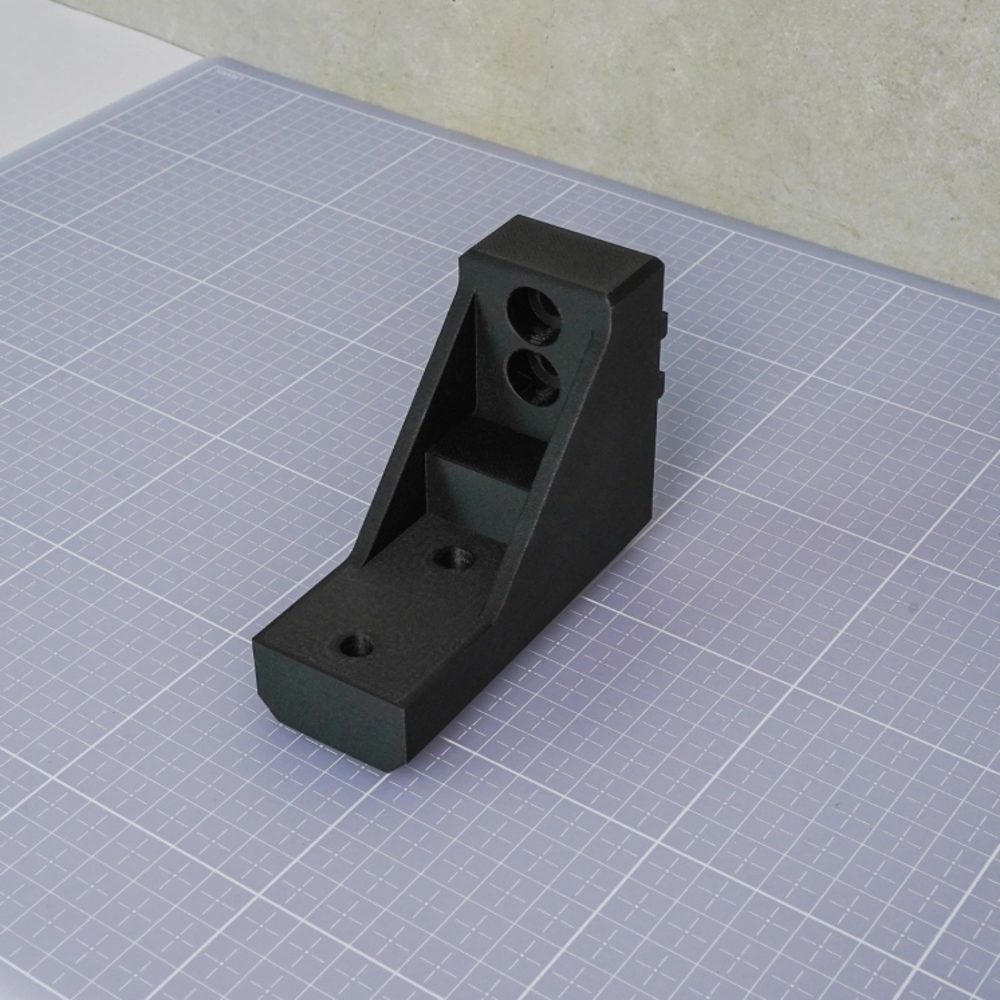

Our manufacturing capabilities

With hundreds of manufacturers in our network, Protolabs Network (formerly Hubs) offers a very broad range of manufacturing capabilities and support both one-off prototyping and low-volume production. We pride ourselves on being the go-to manufacturer for geometrically complex parts or highly cosmetic parts.

Limitless manufacturing

Protolabs is a world first. We are the only solution that pairs in-house factories with a highly vetted global network to provide customers with all-in manufacturing. Access Protolabs factories for accelerated manufacturing of quality parts or use Protolabs Network for volume pricing, tighter tolerances, and more complex parts. The result? Digital manufacturing and engineering expertise that meets all your needs from prototyping to production.

Meet our vetted network of specialized manufacturing partners

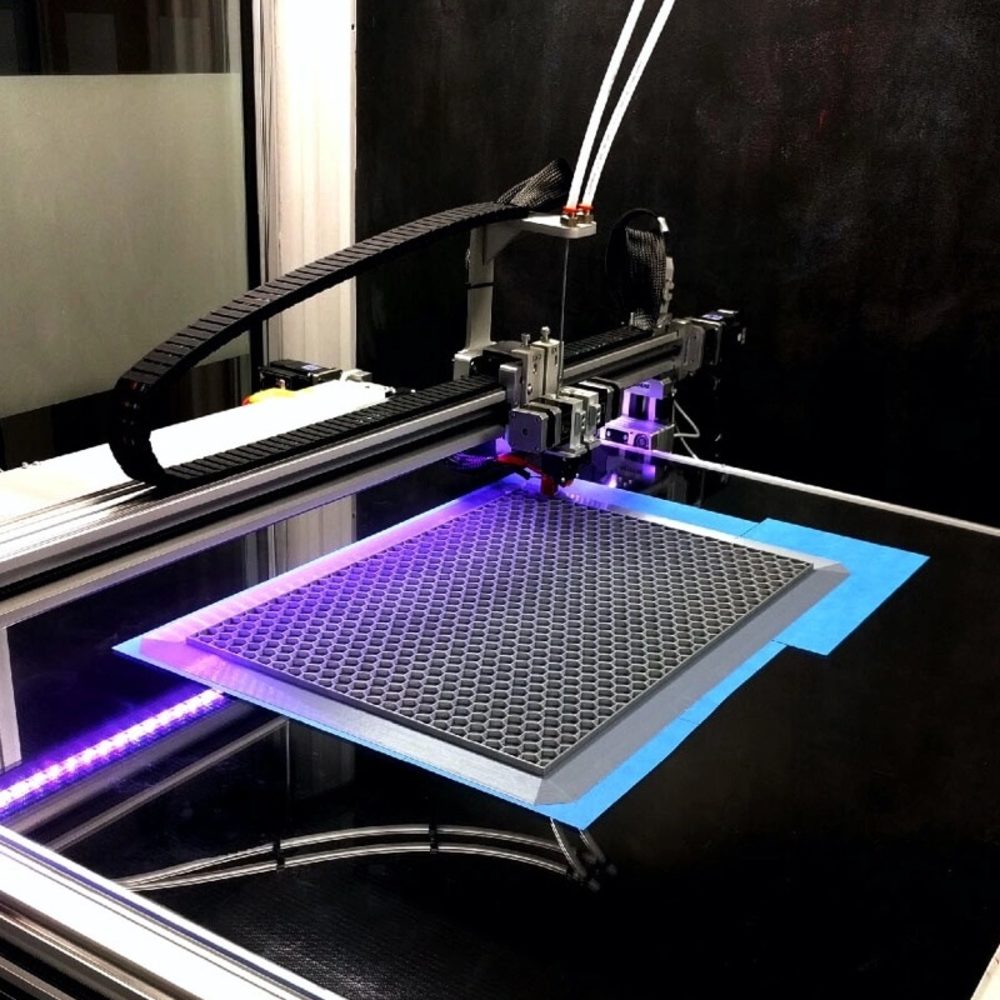

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

3D printing factory in Netherlands

| Established | 2014 |

| Number of machines | 5 |

| Capabilities | SLS |

3D printing facility in Texas, US

| Established | 2014 |

| Capabilities | MJF, FDM |

| Machines | 63 |

| Equipment | HP 3D Jet Fusion 4200 |

3D printing factory in United Kingdom

| Established | 2014 |

| Number of machines | 13 |

| Capabilities | SLS, FDM |

CNC machining factory in India

| Established | 2019 |

| Capabilities | CNC Machining 5, 4, 3 Axis. Mill Turn and turning |

| Machines | Mazak & Doosan |

| Expertise | Fast, low-cost prototyping. Strong and complex end-use parts |

| Description | Specializes in highly complex parts with difficult geometries and tight tolerances |

Sheet metal facility in Shenzhen, China

| Established | 2014 |

| Capabilities | Laser cutting, bending, post processing |

| Machines | 66 |

| Equipment | Amada RG 100 CNC Brake, Trumpf 200 Turret Punch Press |

CNC machining factory in China

| Established | 2015 |

| Capabilities | CNC parts for the medical and consumer products industries |

| Machines | 40 CNC machines, 6 CNC bending presses |

| Expertise | Visual prototypes and functional end parts |

| Description | Produce end-product parts with high cosmetic requirements |

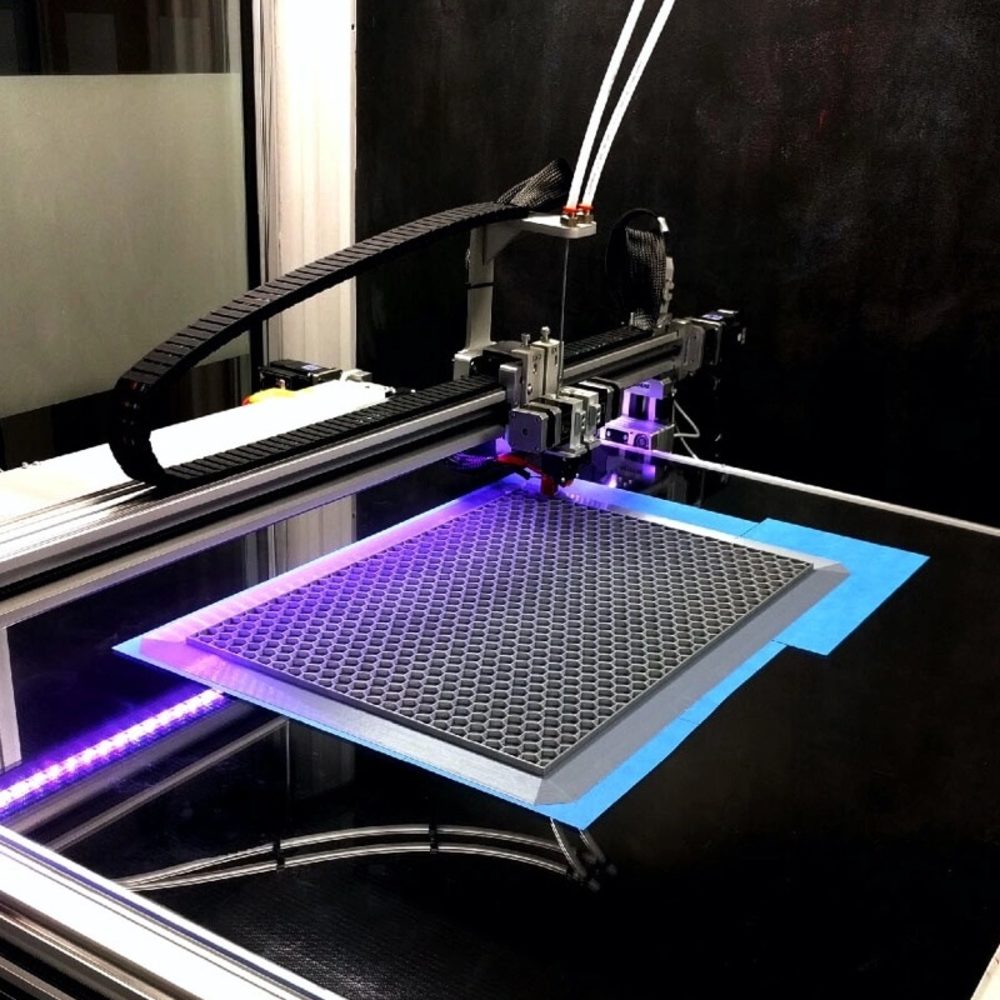

Instant, online quotes

Instead of traditional, rules-based quoting, we use machine learning algorithms to compare your CAD to millions of previously manufactured parts and generate a quote instantly.

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT or X_T)

-

Price updates in real-time as you change materials, lead times, and other order specifications

-

We handle customs clearance and cover import duties on orders shipped to the EU, UK, and US

Our ordering process

Upload CAD file

Securely upload your part design to our online quote builder

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Receive instant quote

Upload your CAD to our online quoting platform

Manufacturing

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Manufactured through Protolabs Network

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

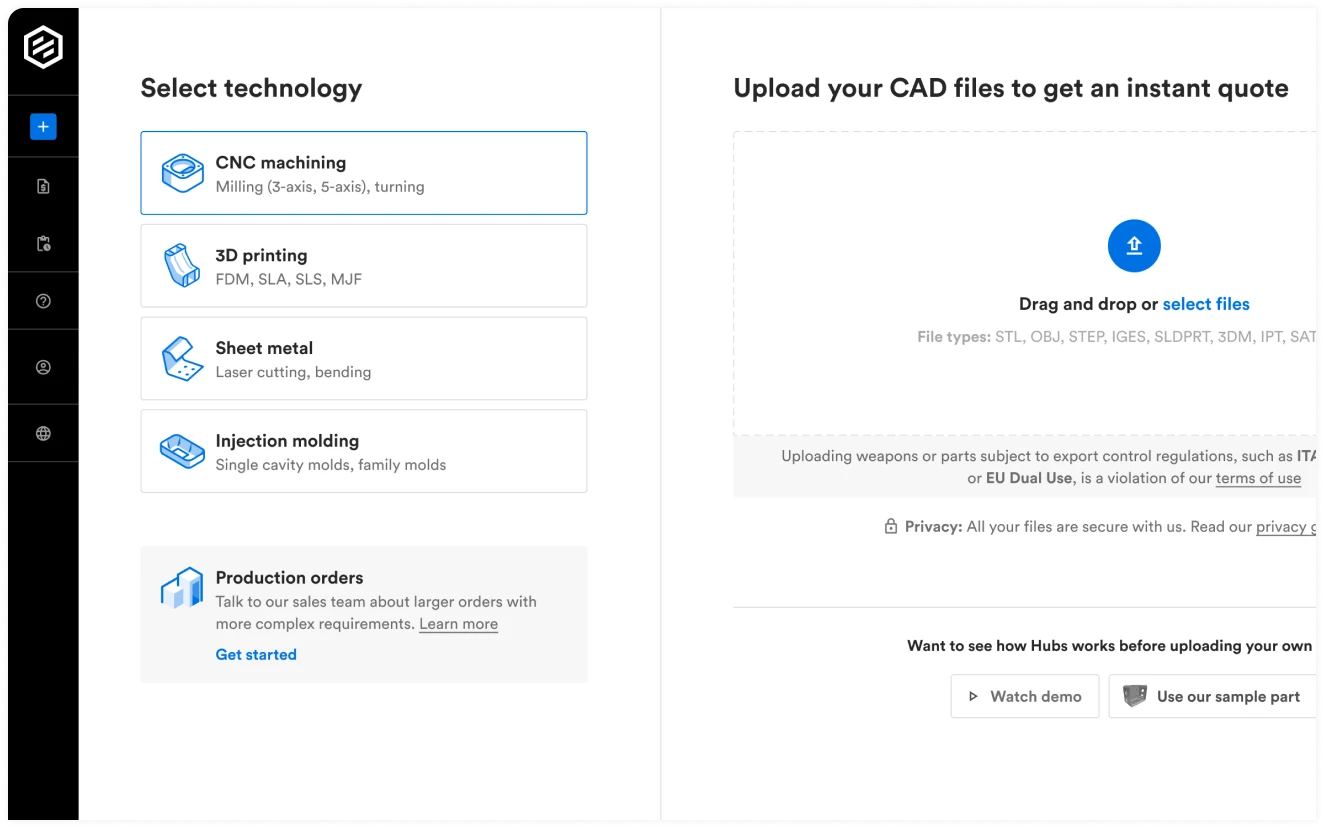

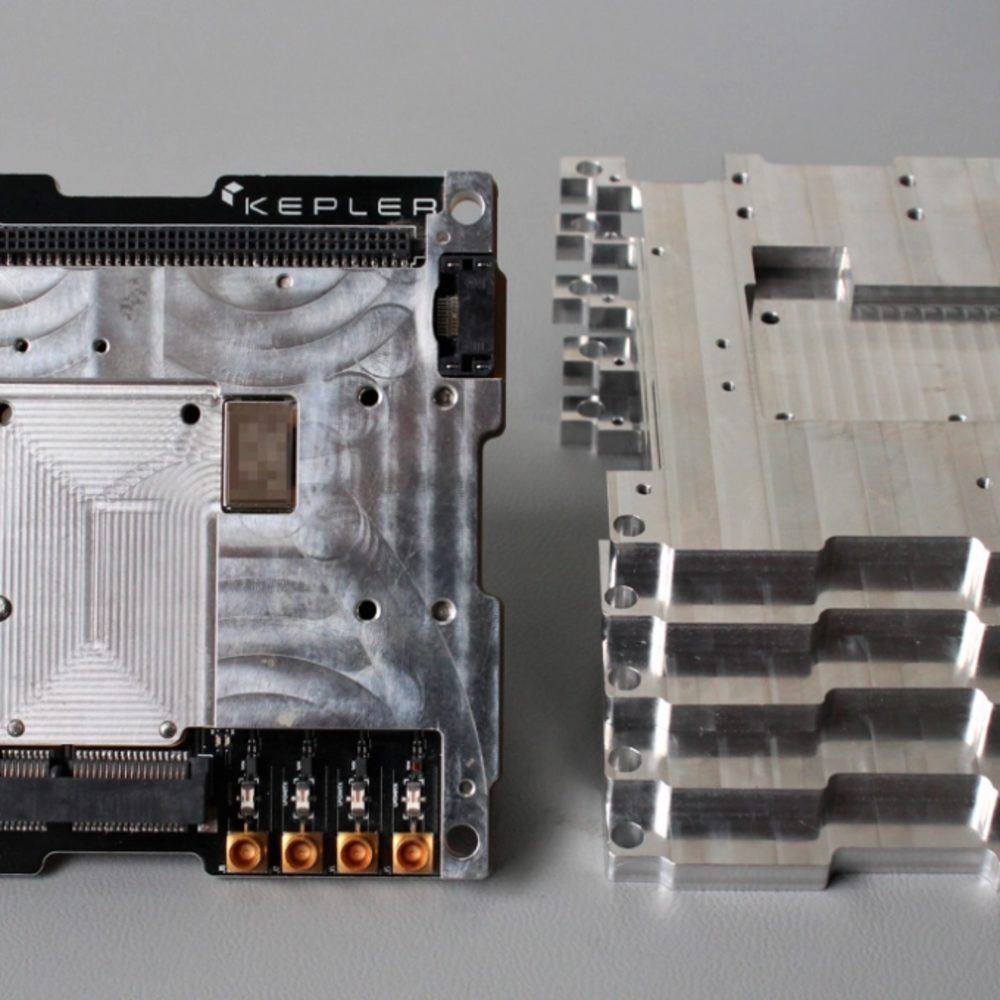

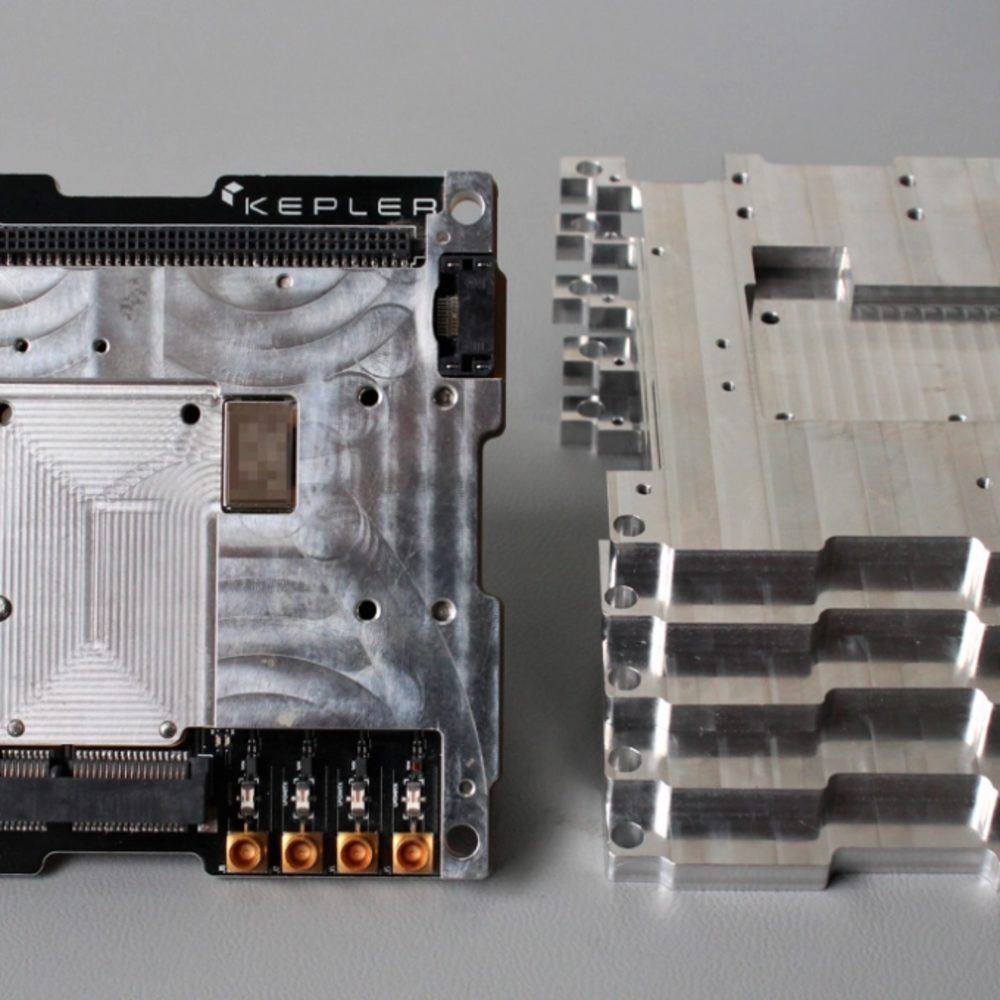

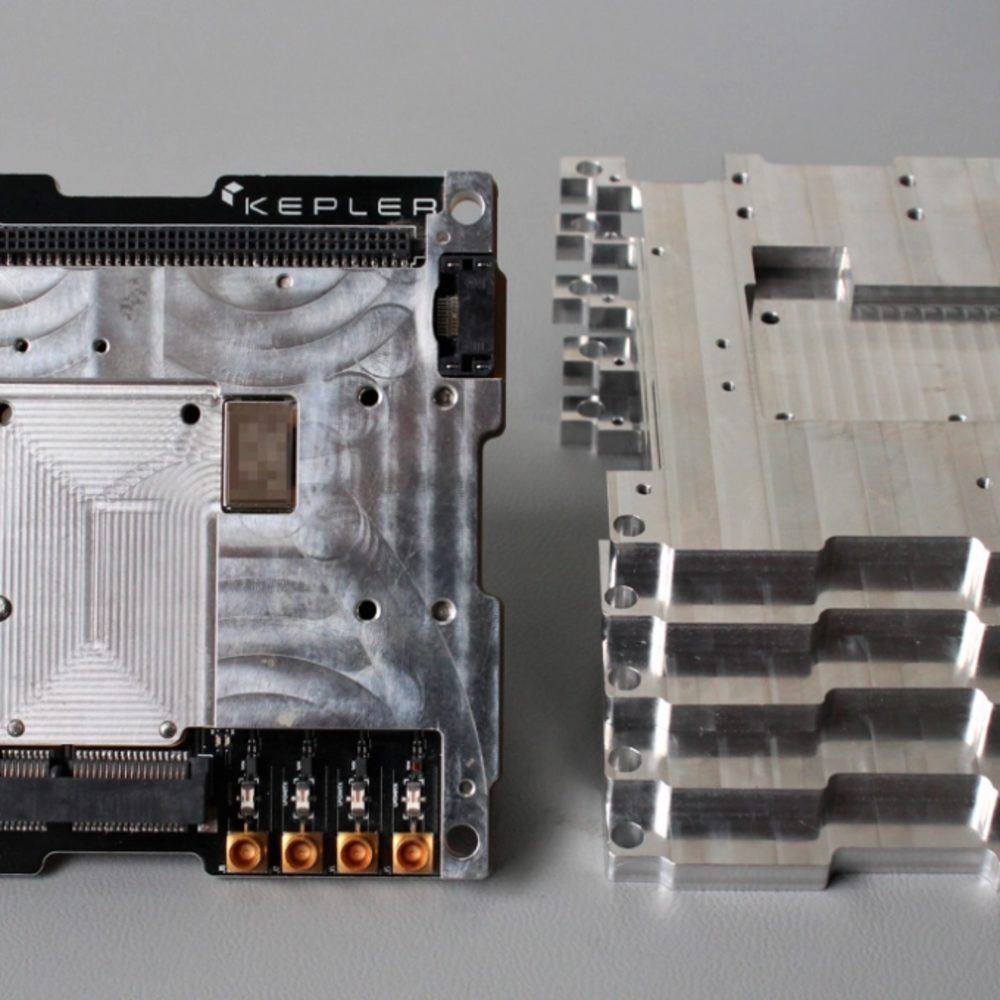

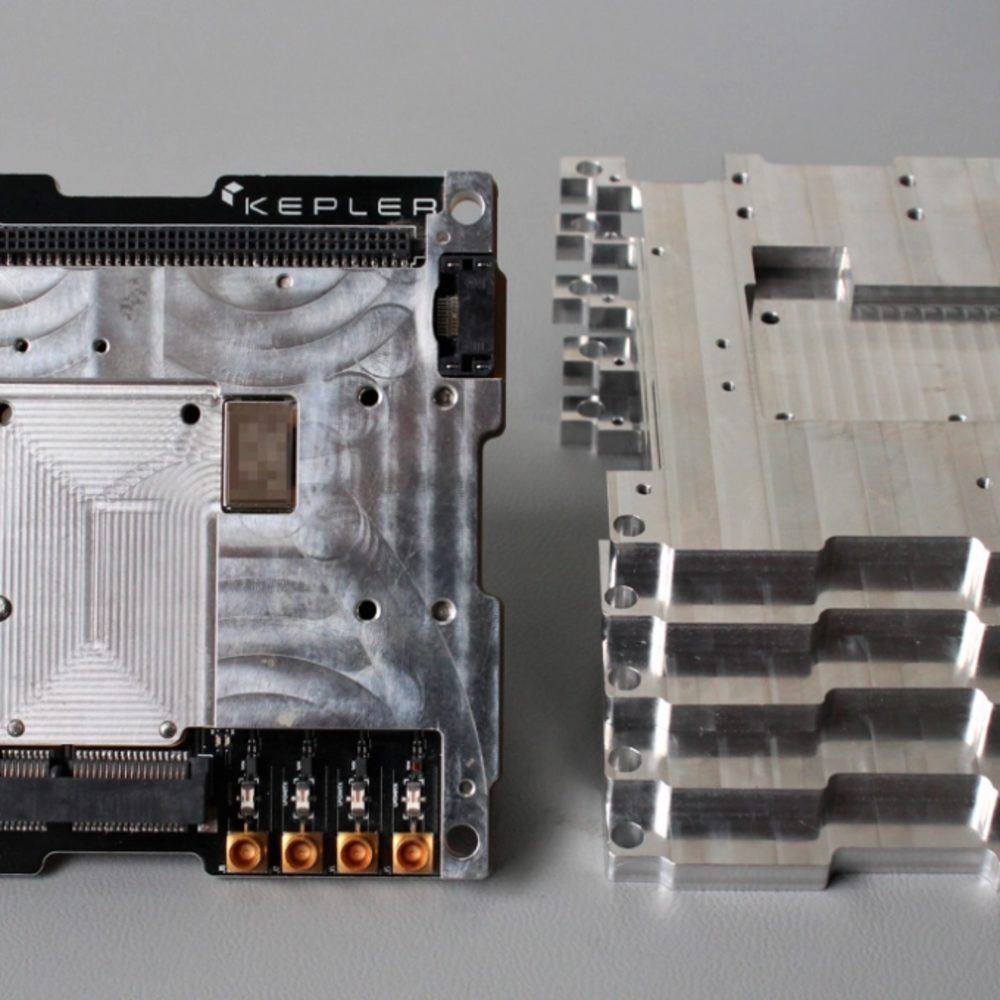

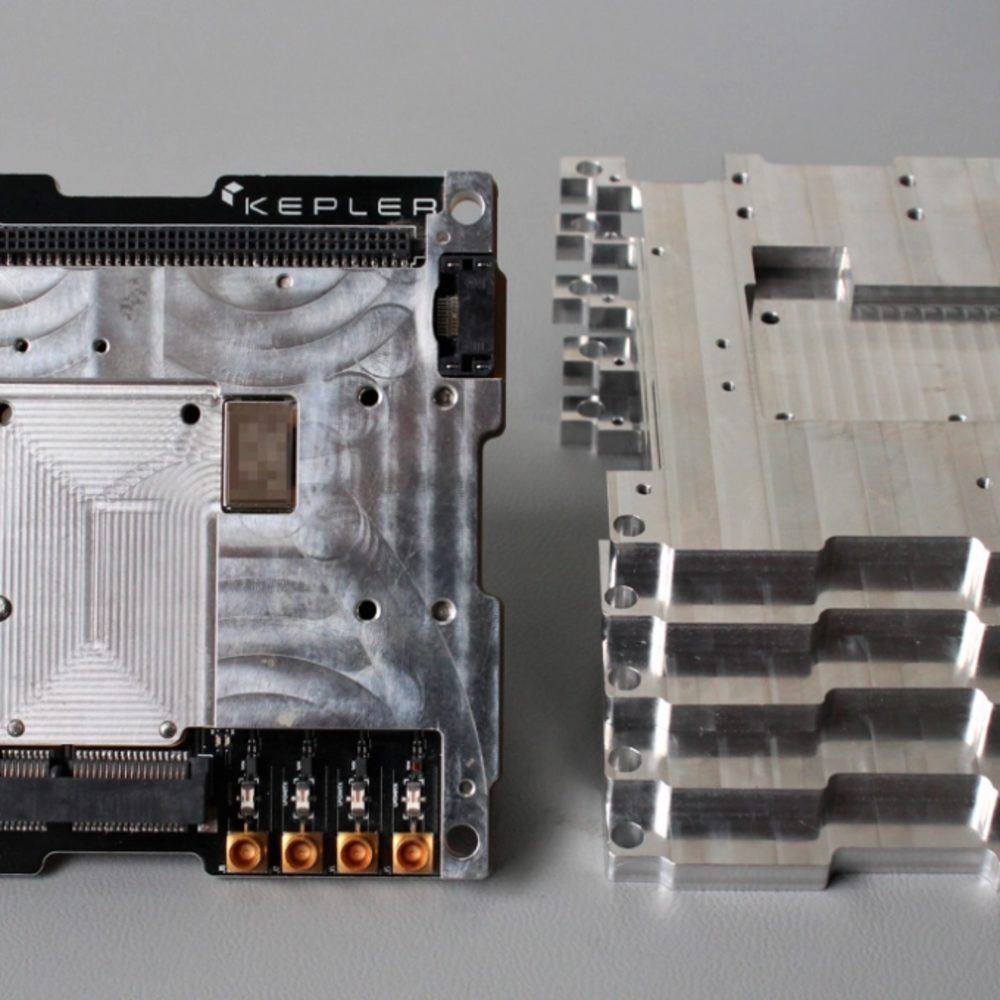

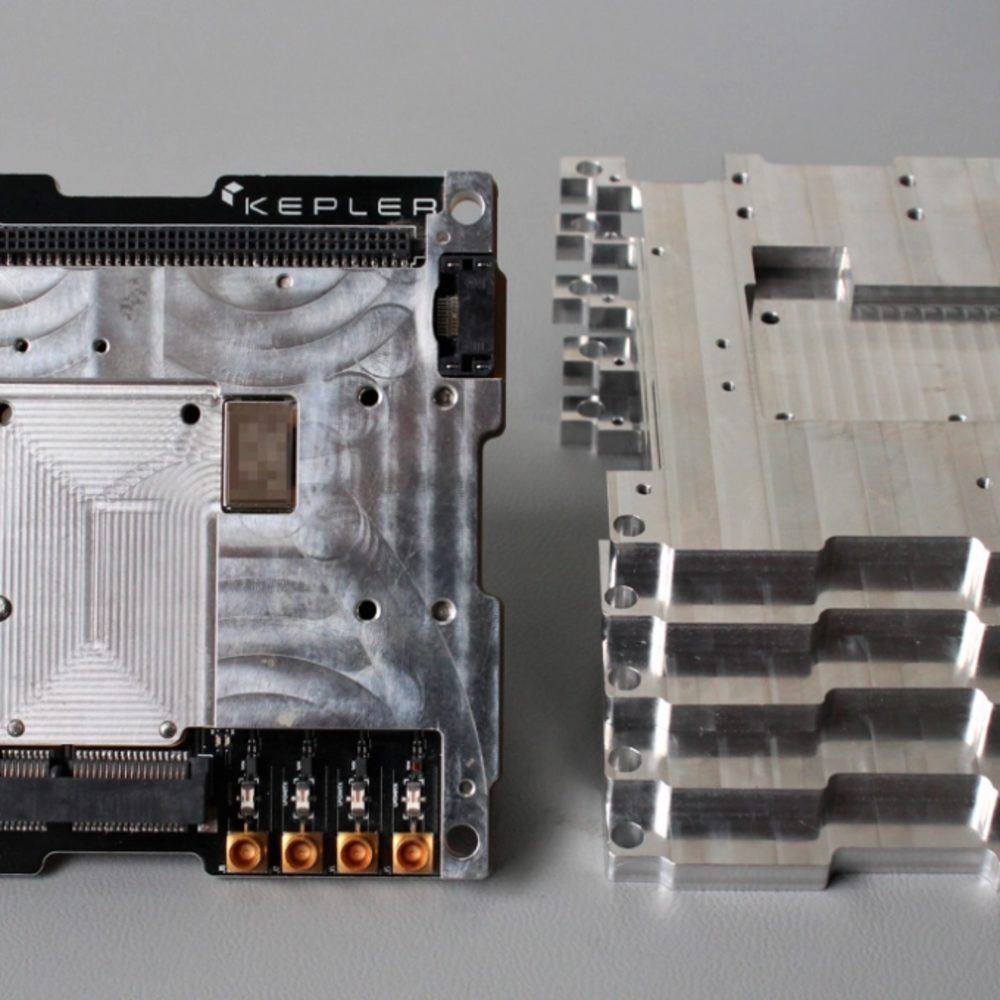

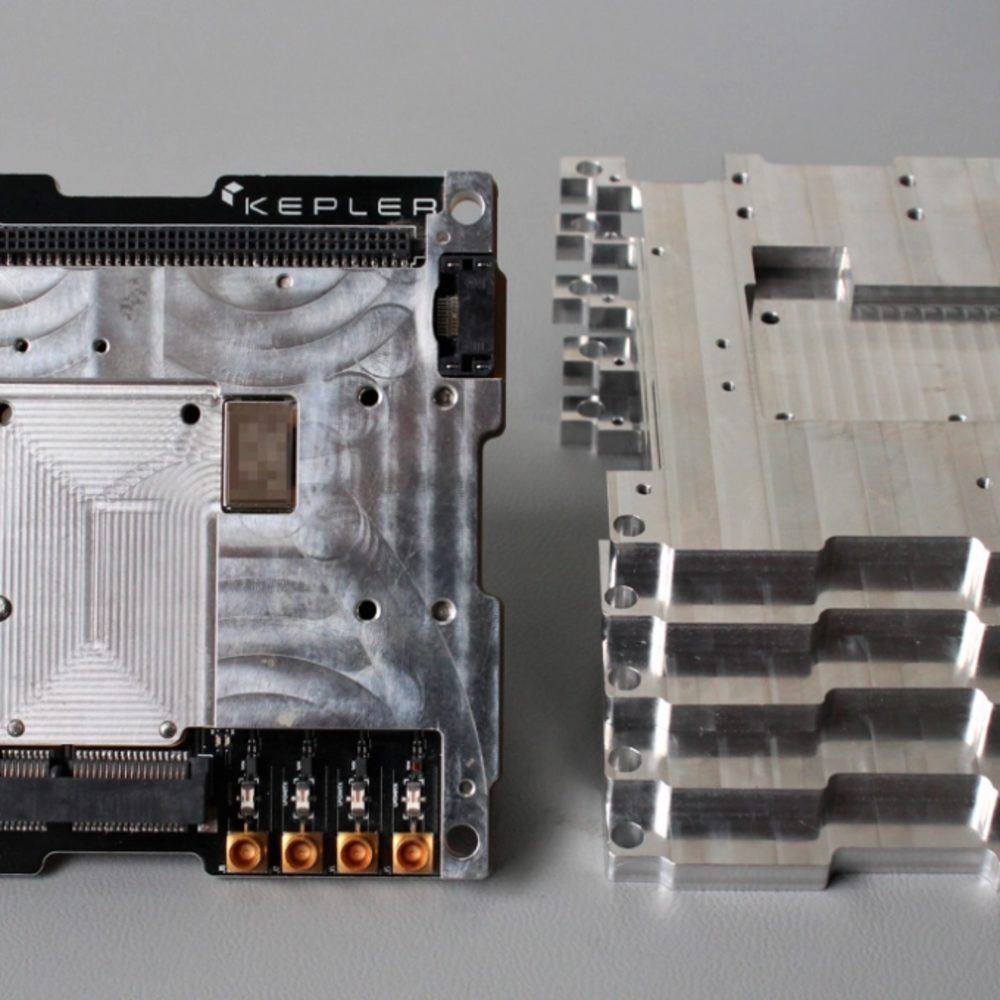

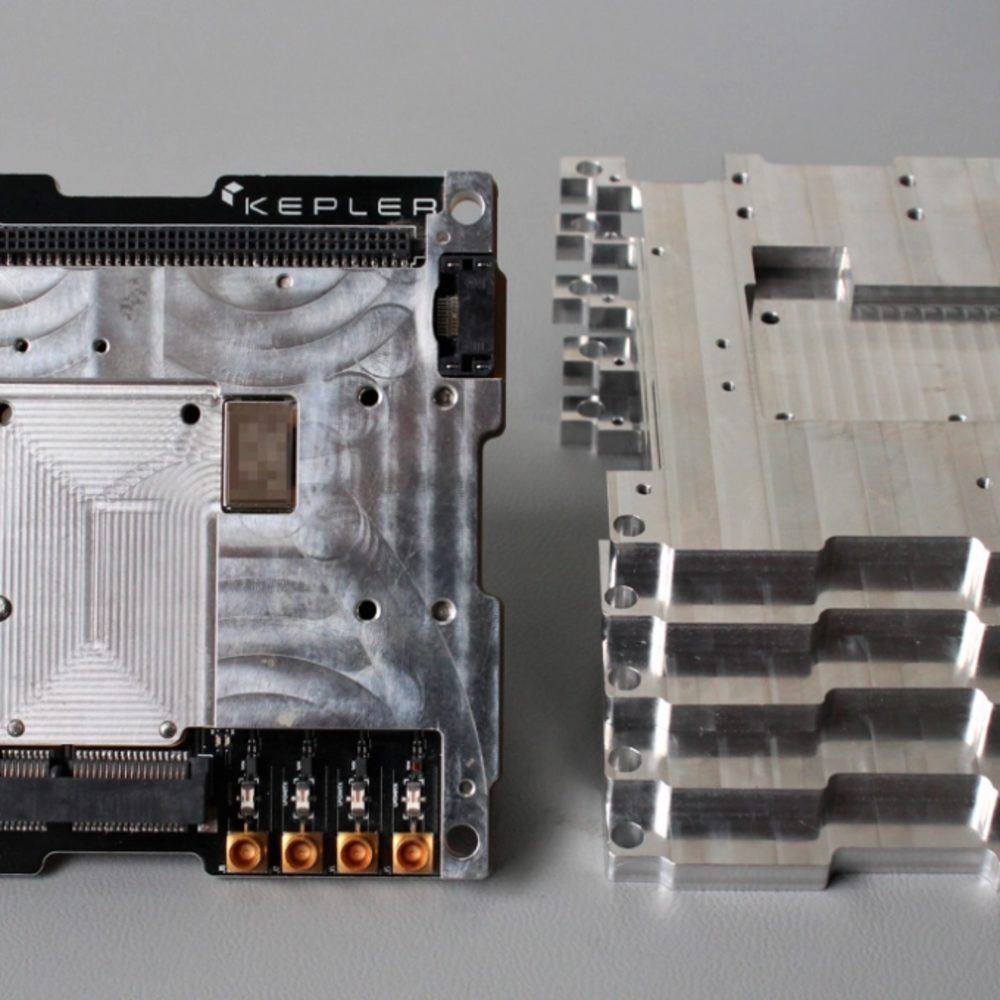

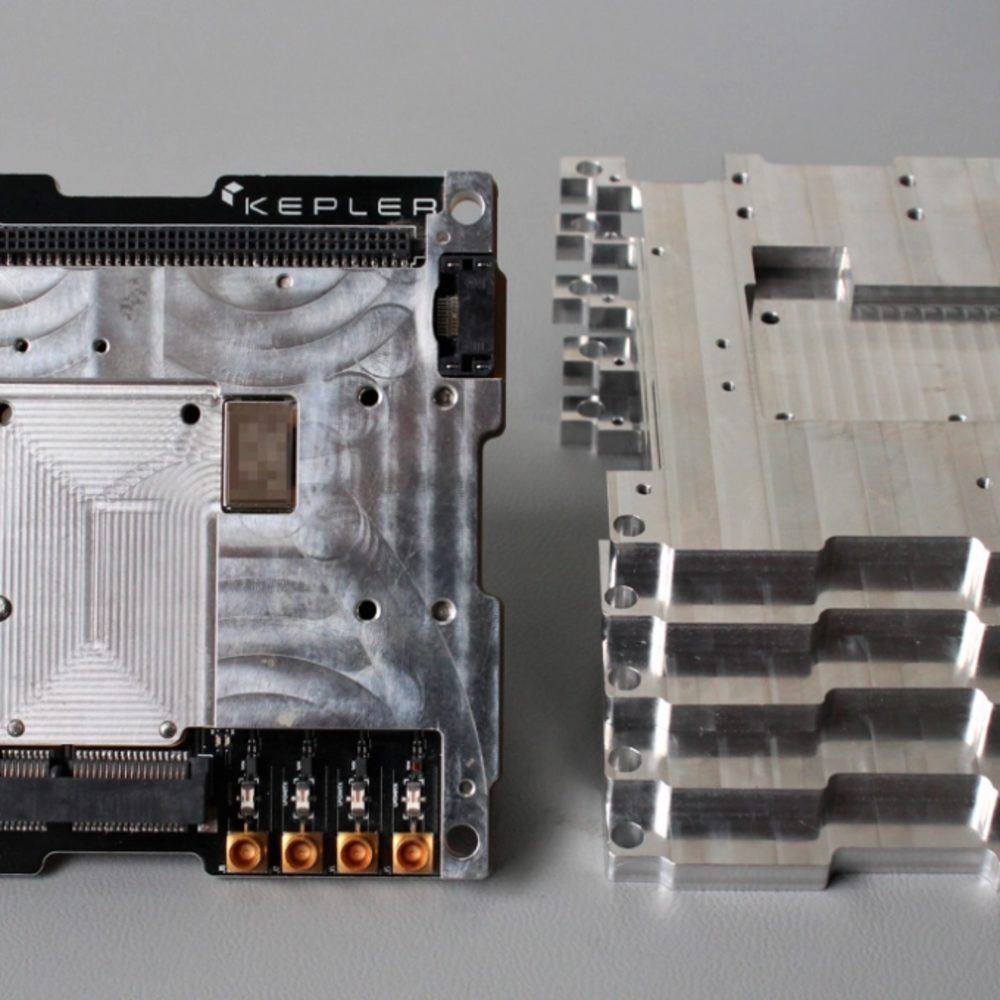

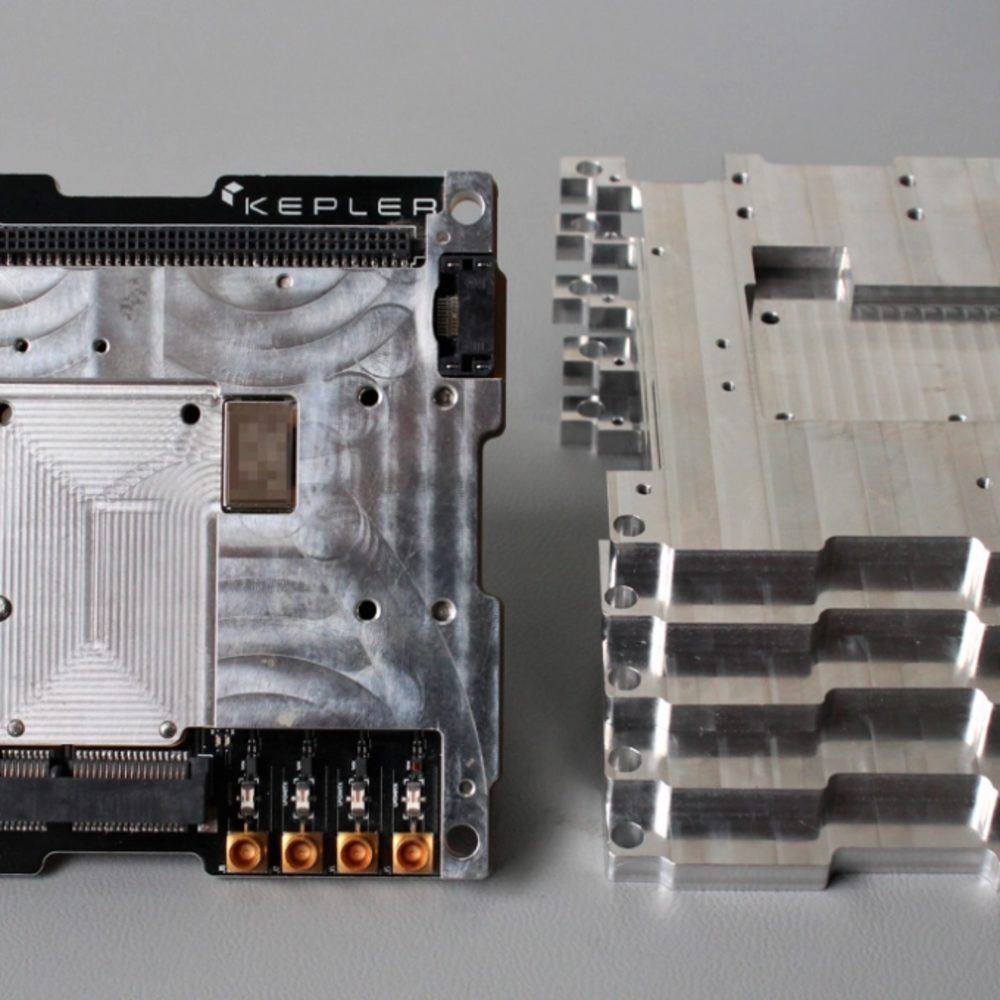

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Airbus

Protolabs’ combined manufacturing solution helps the leading aircraft innovator to develop batteries.

Kepler

Learn how Kepler rapidly went from a sketch on a napkin to a satellite in space with Protolabs Network CNC machining

Mondraker

Find out how the Mondraker bicycle company used Protolabs Network to create custom bike parts in time for its pro mountain bikers to podium at Maribor track in the 2021 UCI Mountain Bike World Cup.

Fillauer

Fillauer Composites uses carbon-fiber and fiberglass to build prosthetic feet. Fillauer partnered with Protolabs Network to reduce the cost of production and open up more time for their engineers to focus on perfecting the designs.

Skelex

Skelex exoskeletons make your arms feel weightless using dynamic balancing. They also managed to solve the biggest challenge many hardware startups face: manufacturing-on-demand when a new opportunity arises.

DroneSeed

What if you could fight climate change with a fleet of tree-planting drones? That’s what DroneSeed is striving towards. With custom-built drones for each project and tight turnaround times, the Seattle-based startup leverages rapid manufacturing technologies to stay nimble.

Lektri.co

LEKTRI.CO is on a mission to make electric vehicle use more accessible and efficient. Learn how the telematics innovator designed its new destination chargers and how Protolabs Network built the robust casing and cover to match its futuristic design.

Ampyx Power

Find out how Protolabs Network helped Ampyx Power hit major milestones in its mission to develop a better way to harvest wind energy with autonomous aviation technology.

Snorricam

Protolabs Network's quote builder and decentralized manufacturing model helped SnorriCam optimize designs quickly and produce professional-grade parts in boutique quantities. Find out how Protolabs Network helps SnorriCam manufacture custom professional camera rigs for indie projects and global blockbusters alike.

Formify

Formify uses Protolabs Network's platform and Multi Jet Fusion (MJF) to create custom computer mice for pro gamers and casual users alike. Learn how the startup worked with Protolabs Network to produce the most innovative and personalized peripherals in the game.

Langefreunde Design Studio

Find out how Protolabs Network's engineers and manufacturing partners successfully accelerated the product development cycle.

Zinstax

Han Chen, the creator of Zinstax, discusses how he utilized both Hub's network and Protolab's digital factories to manufacture his camera back. He also delves into the inspiration behind his design and his love for film photography.

Relic EDC

How working with Protolabs Network brought in significant business for a CNC machining specialist.

Philips

Protolabs Network and Protolabs worked together to deliver parts demanding both speed and complexity, helping an iconic consumer electronics brand to further improve their coffee machines.

GB MEC

Discover how Protolabs Network assists a traditional marine company to stay competitive through increased efficiency.

Otect

Otect makes specialized metal & plastic lens caps designed to fit Leica cameras perfectly, both in form and quality. Learn how the startup works with Protolabs Network to source high-precision parts that seamlessly fit Leica’s design and uphold the quality level.

Conquering Horizons

Learn how Protolabs Network helped Phil Eaglesham and Conquering Horizons debut their next-gen wheelchair at the Paralympics in 2021, manufacturing and delivering custom complex parts with only a matter of days before the prototype’s debut in Japan.

Hone Shaving

We matched the care and attention in the designs of these products with our manufacturing partners’ expert craftsmanship.

Alutech Cycles

Components for this electric mountain bike required agility, lightweight materials and fast manufacturing. Find out how we overcame the obstacles.

New Infrared Technologies

How New Infrared Technologies’ cameras hit the gas in automotive brake manufacturing.

Envisics

Envisics’ augmented reality head-up displays project information onto drivers’ windshields, bringing the future of automotive innovation that much closer.

Centralized standards for consistent quality

The Protolabs Network Standard is our set of protocols and procedures that ensure the consistent quality of every part we manufacture.

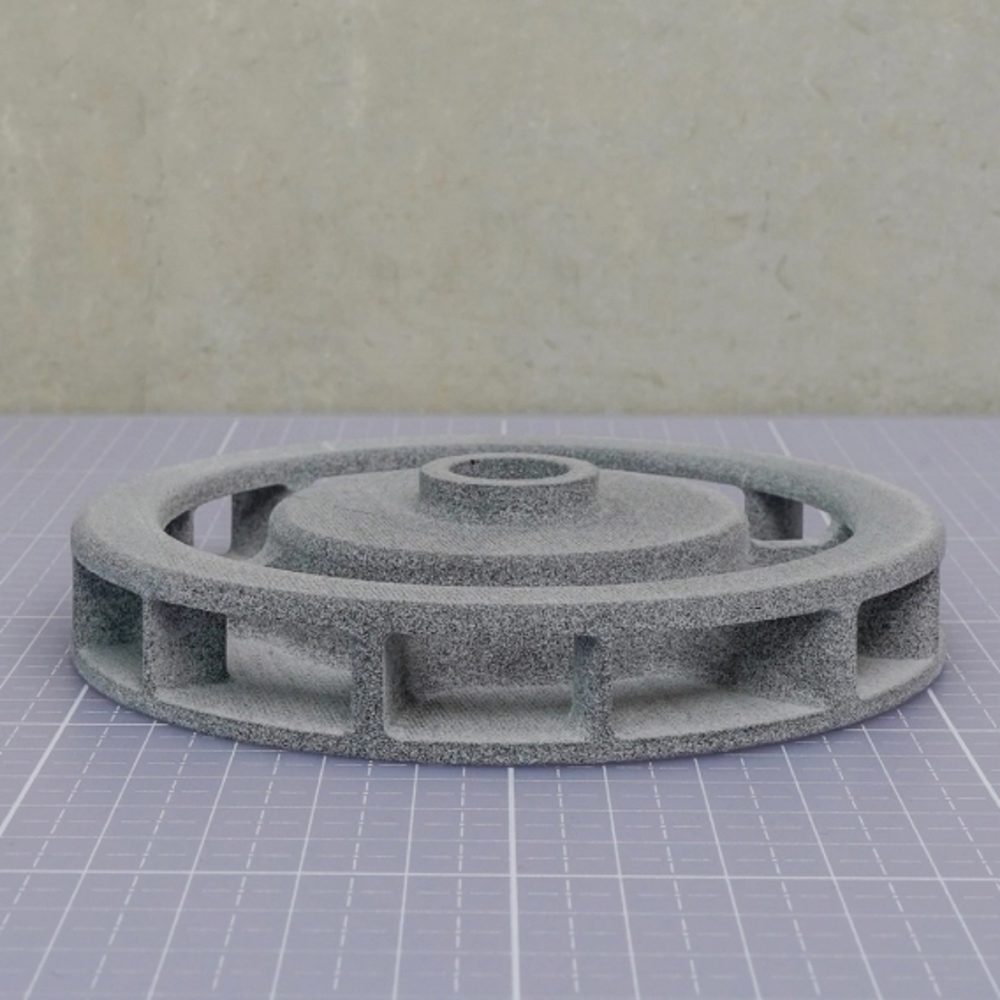

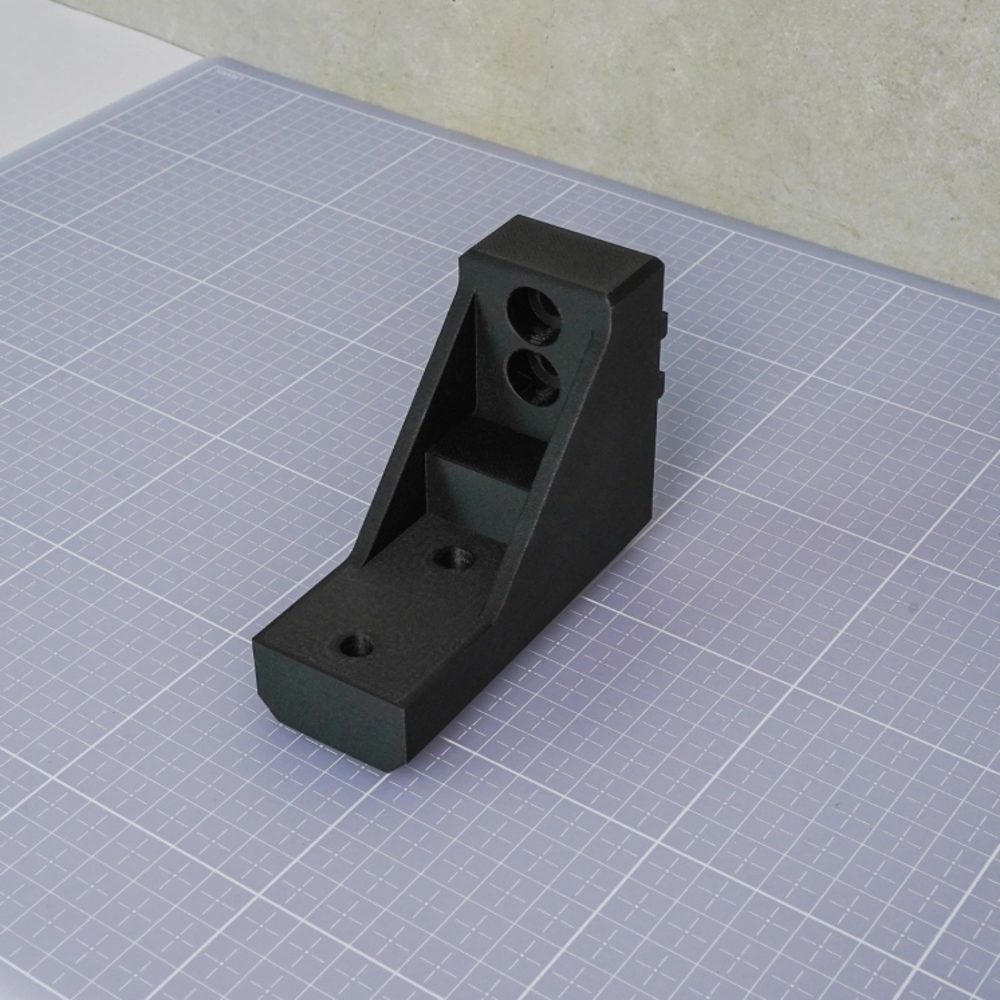

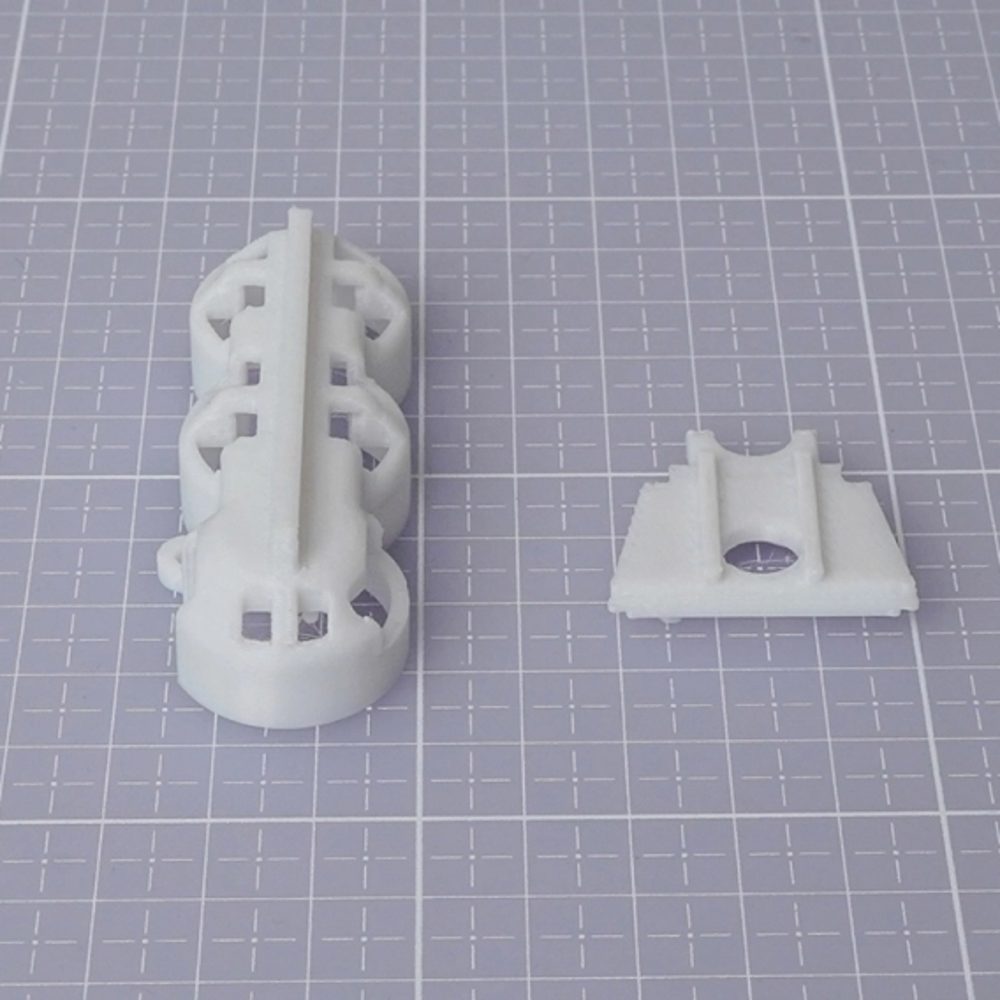

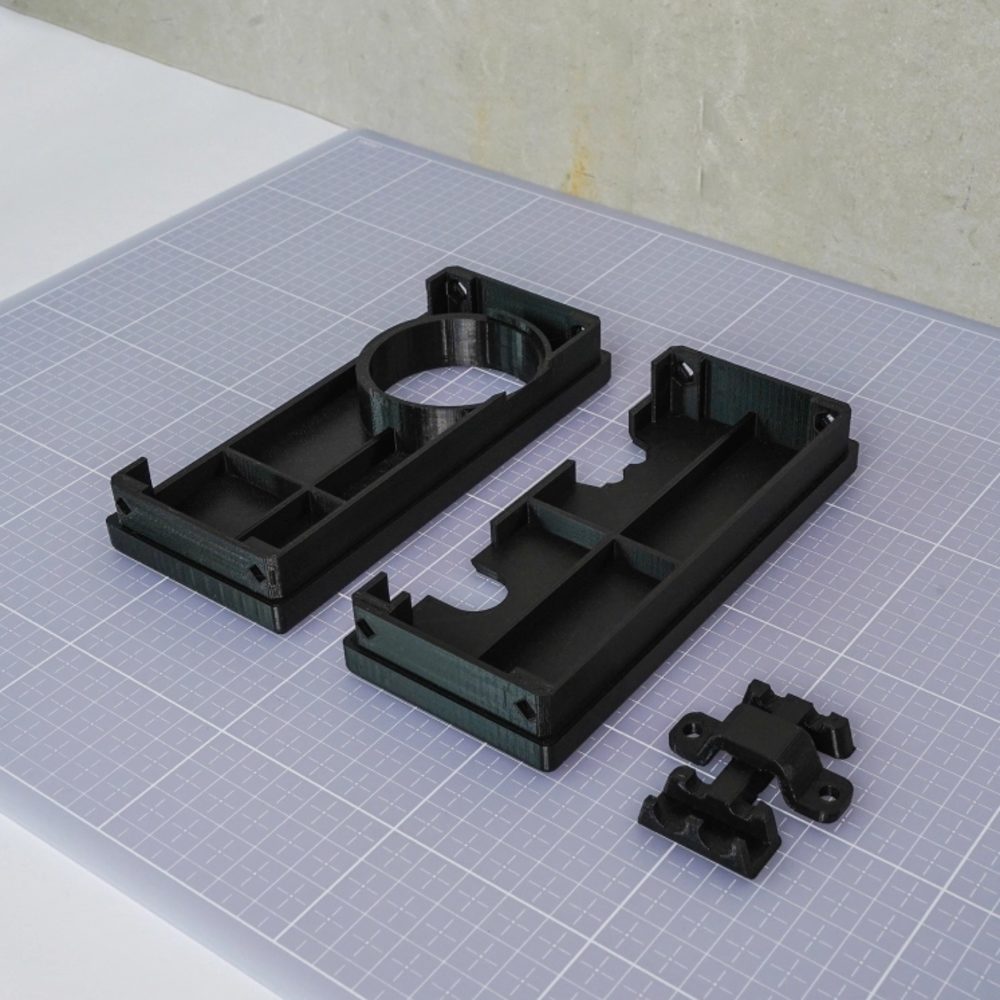

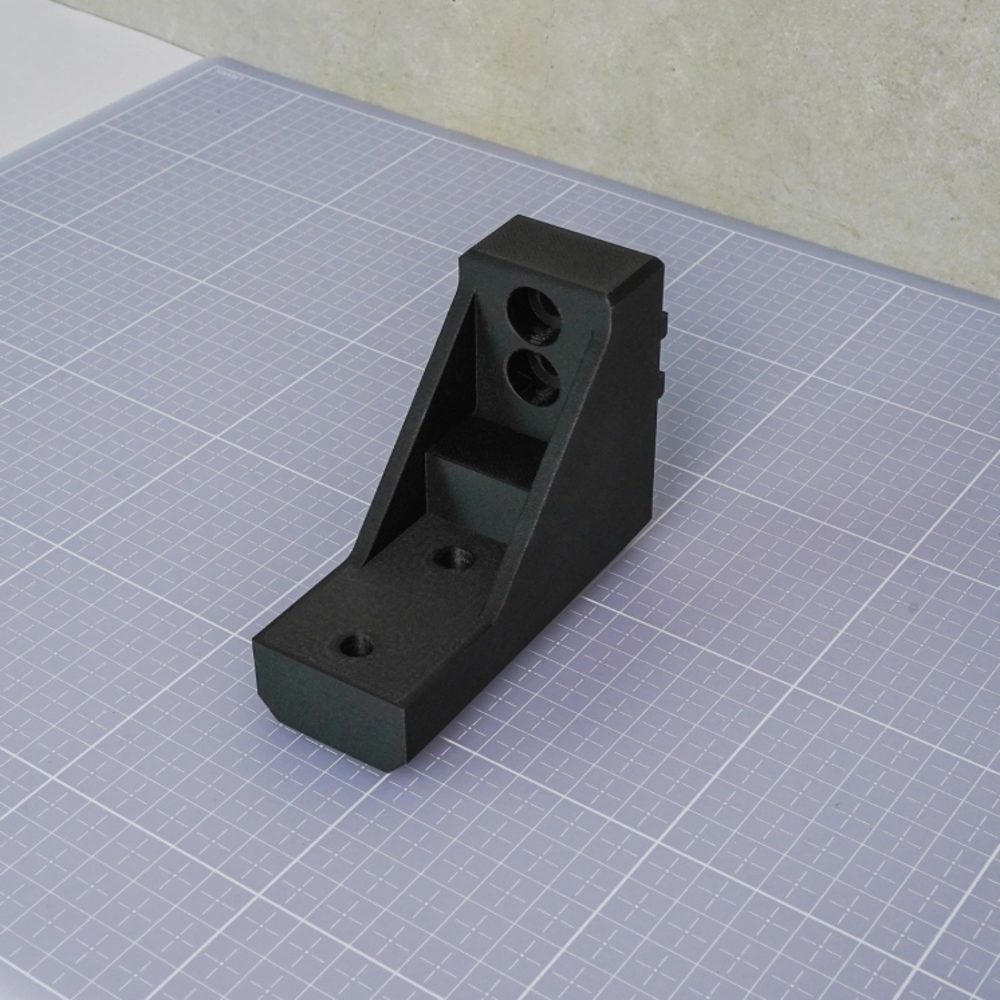

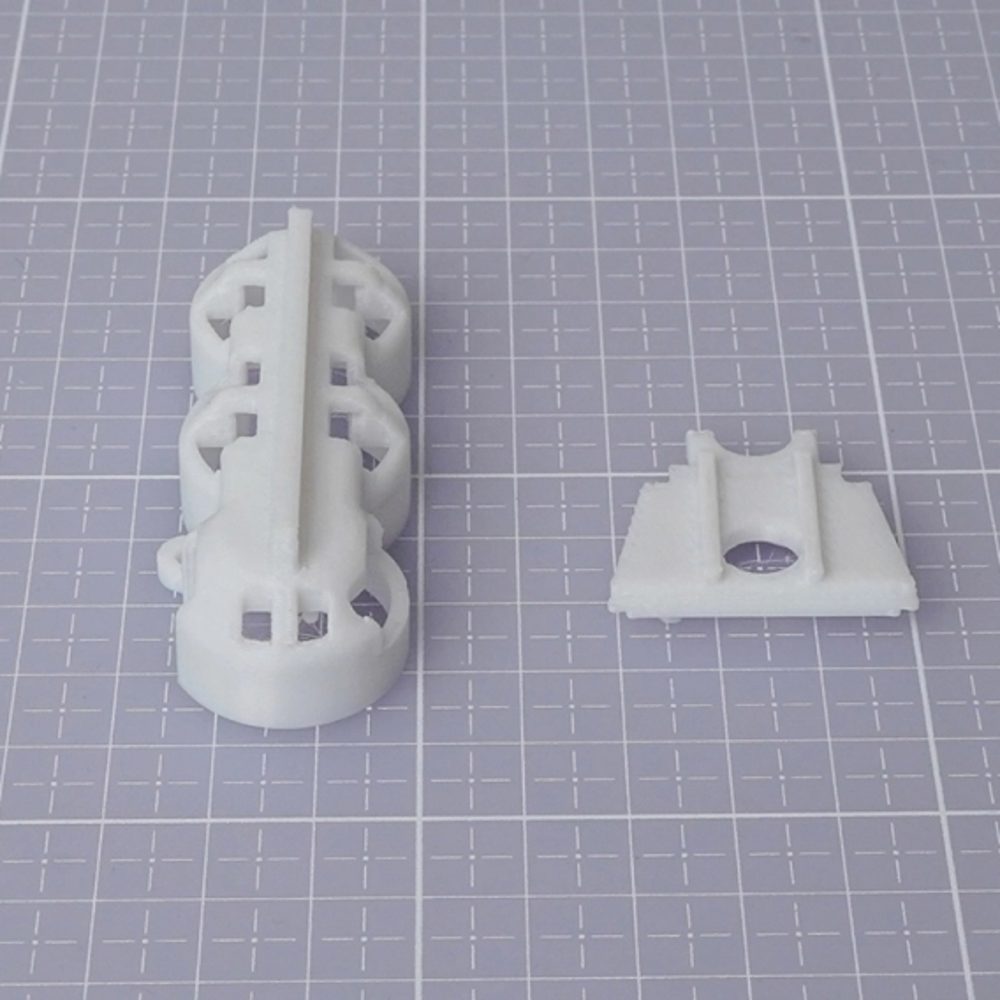

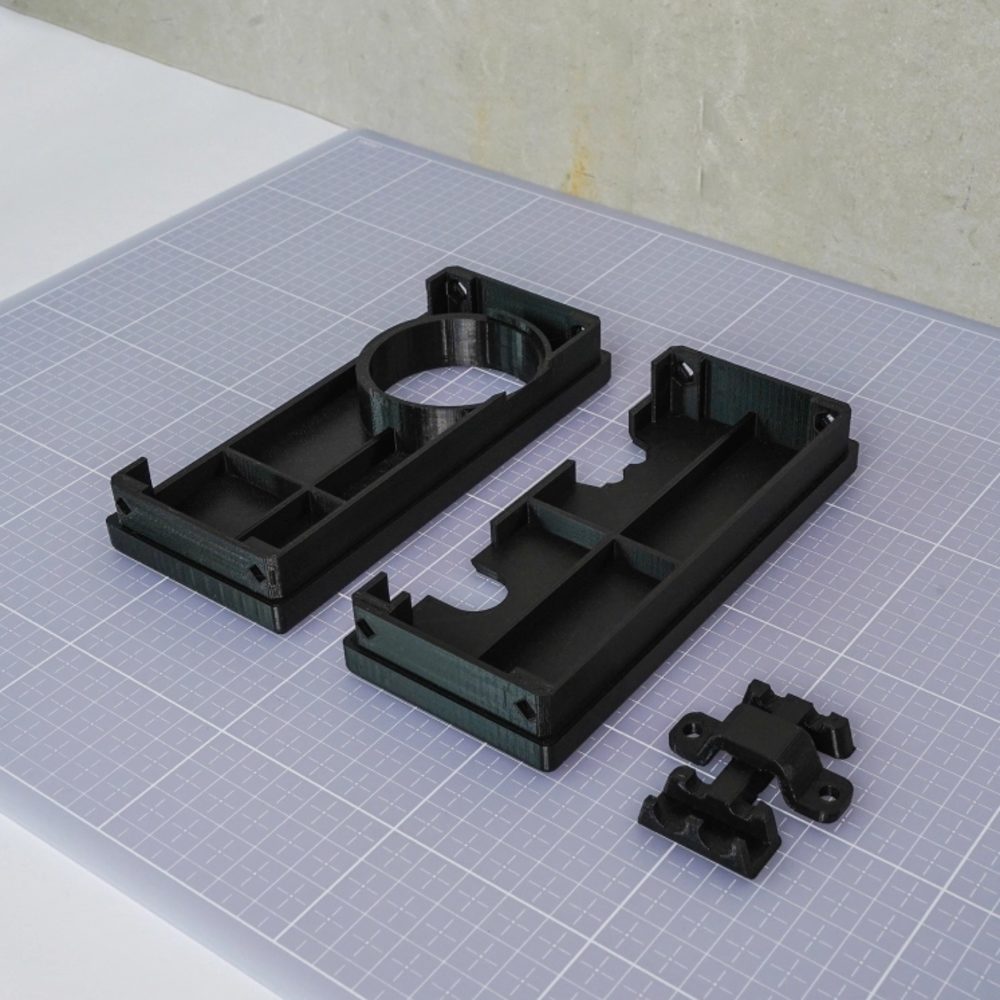

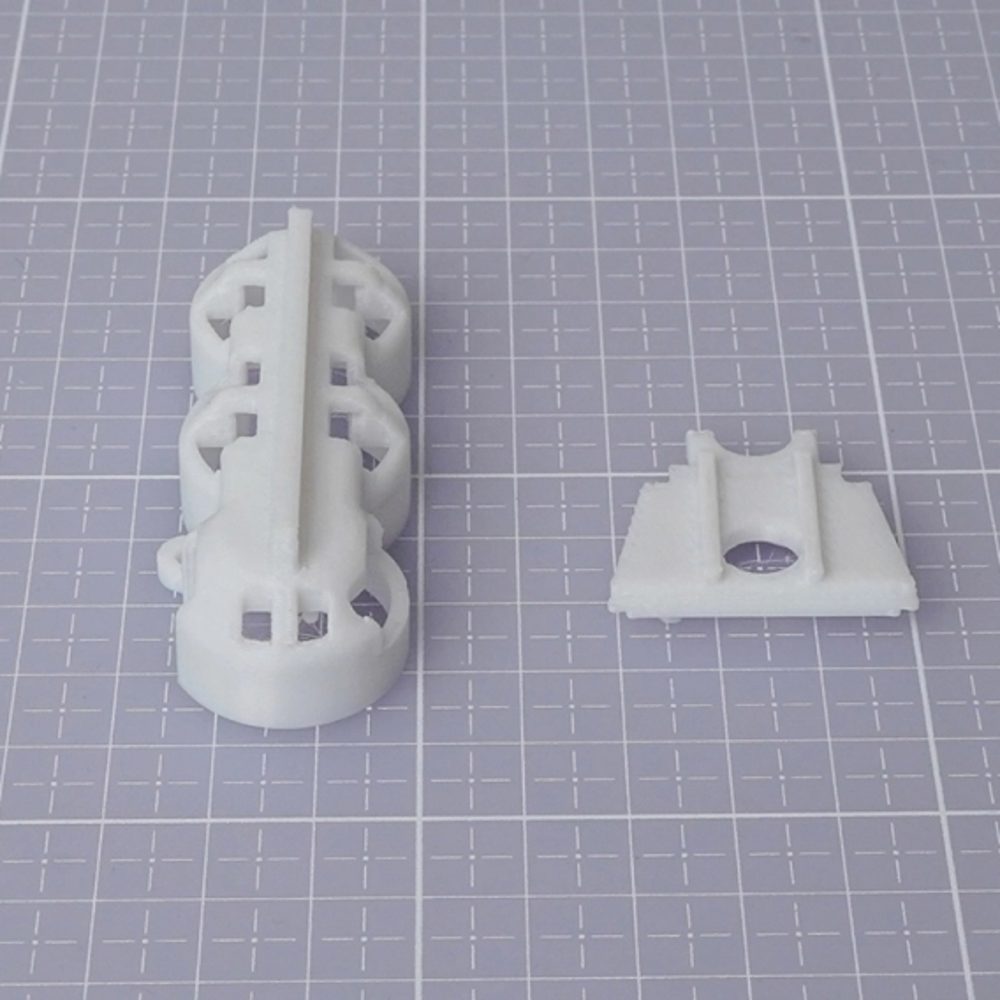

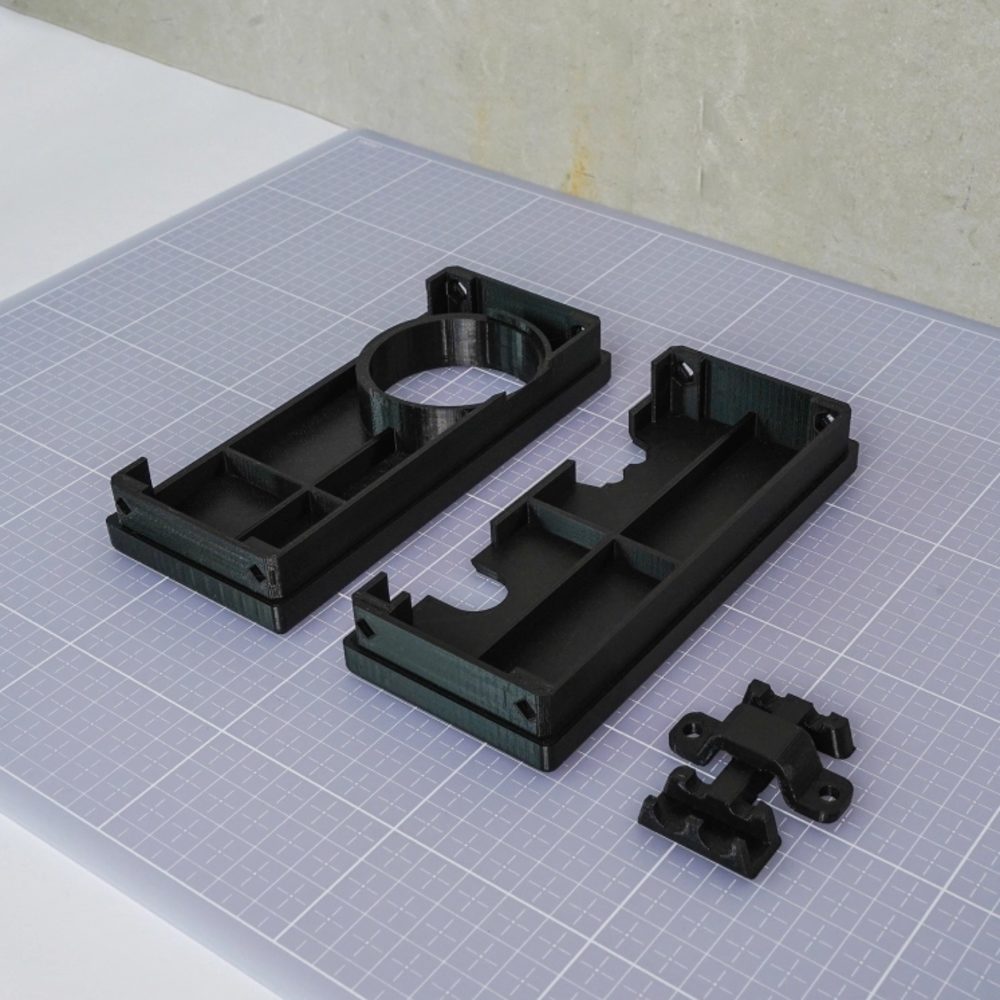

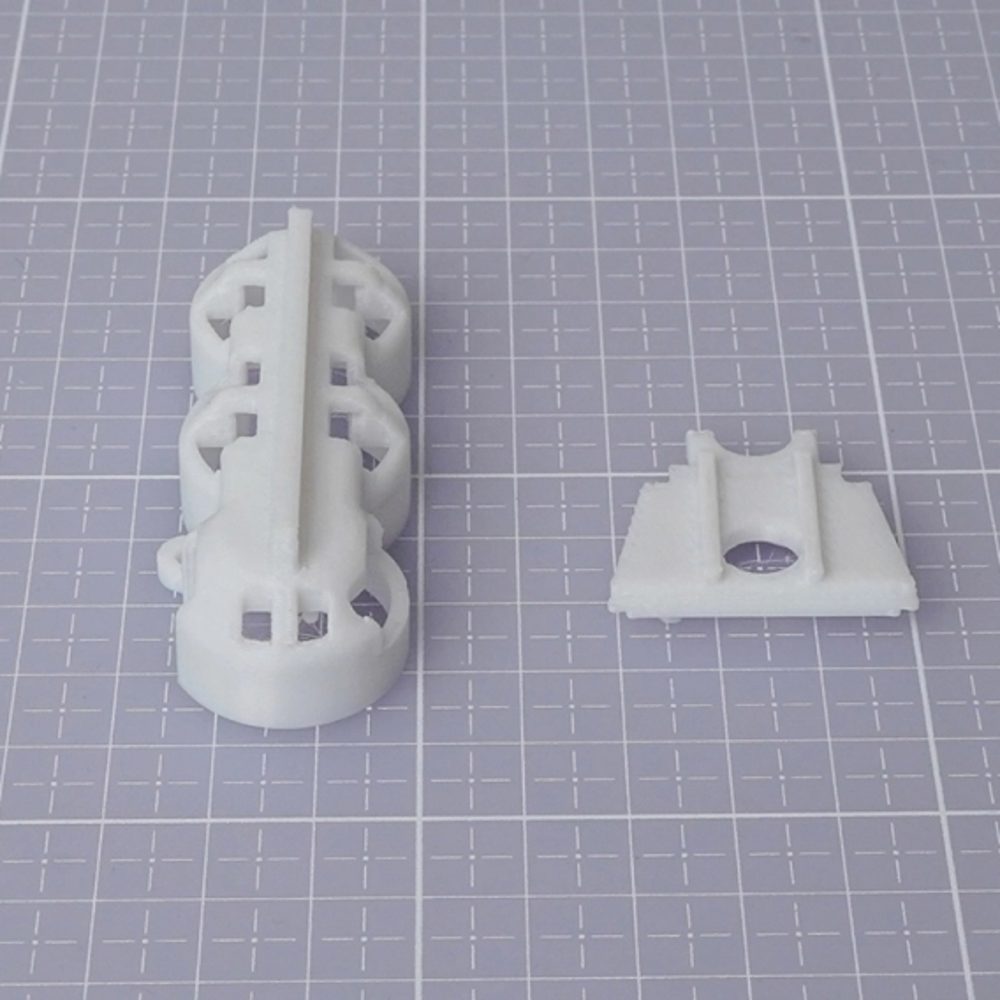

CNC machined and 3D printed parts

Beyond the capabilities on our platform, Protolabs Network can accommodate almost any order requirement, including complex and cosmetic parts, custom materials and a range of post-processing options.

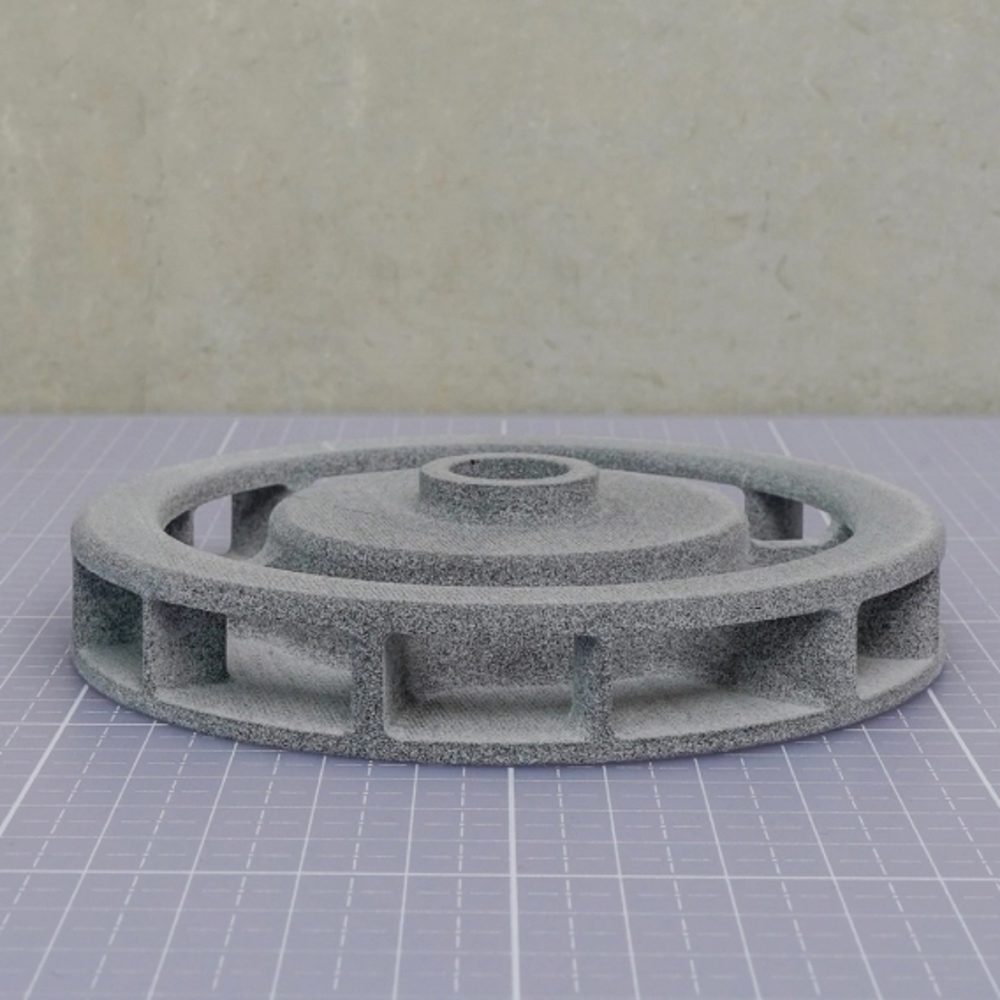

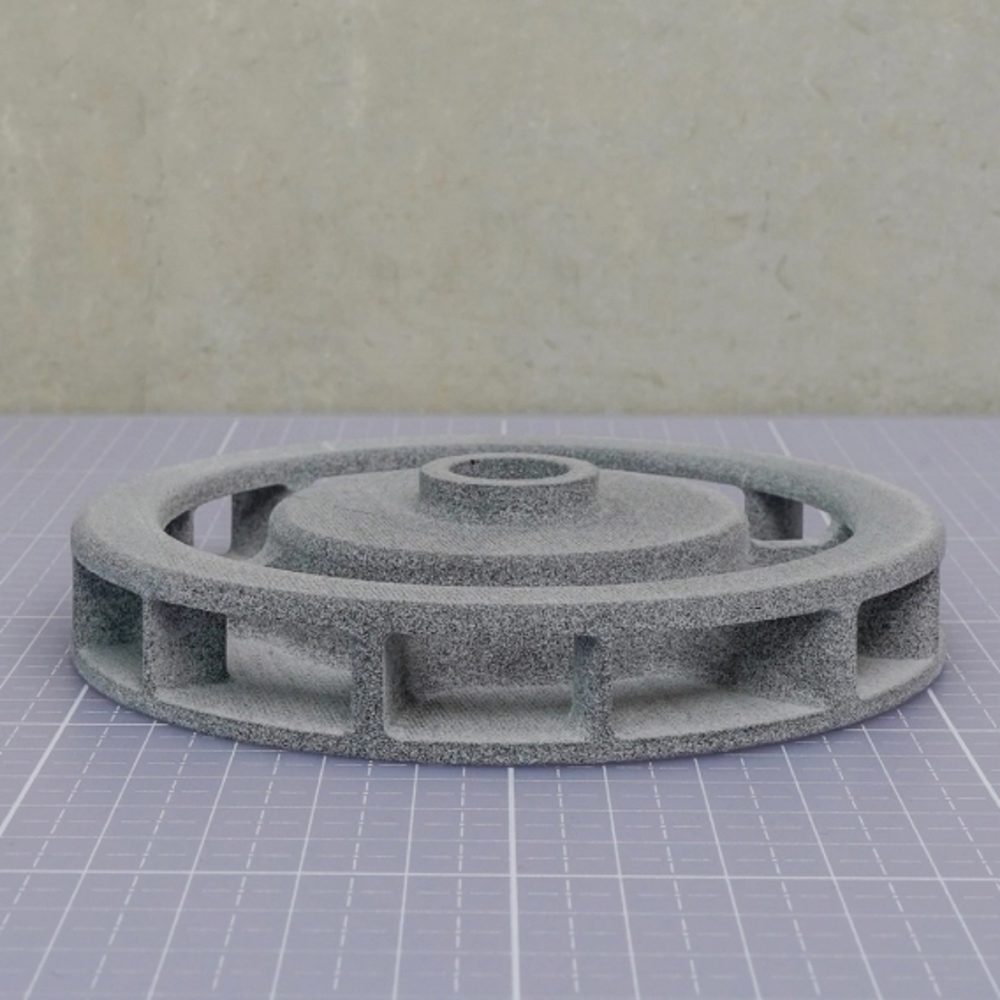

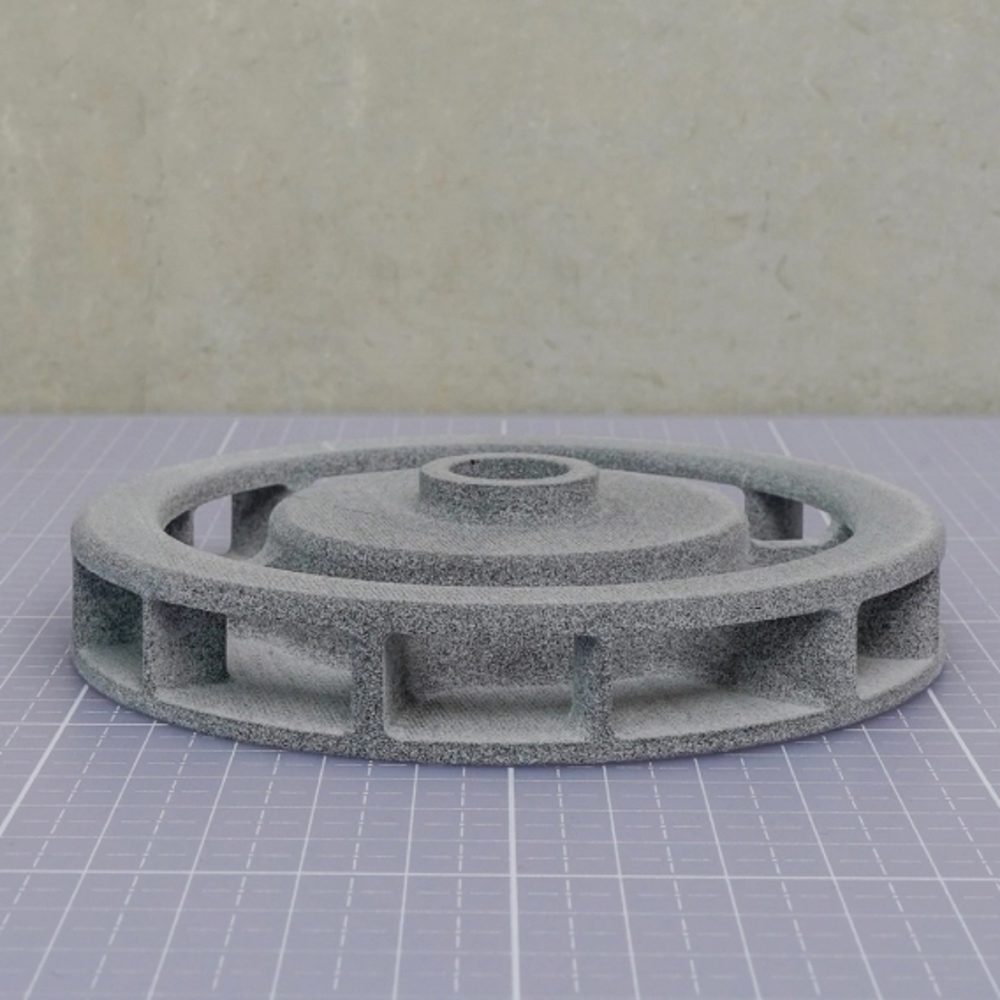

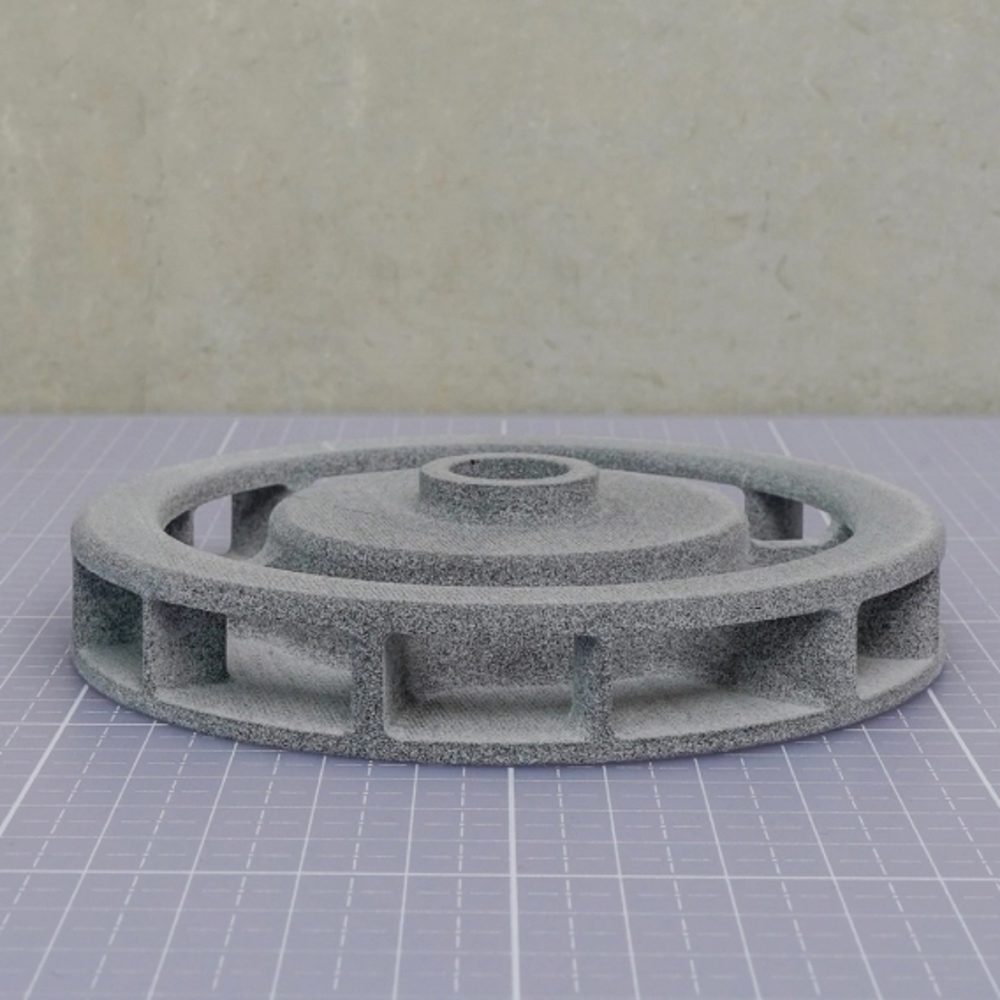

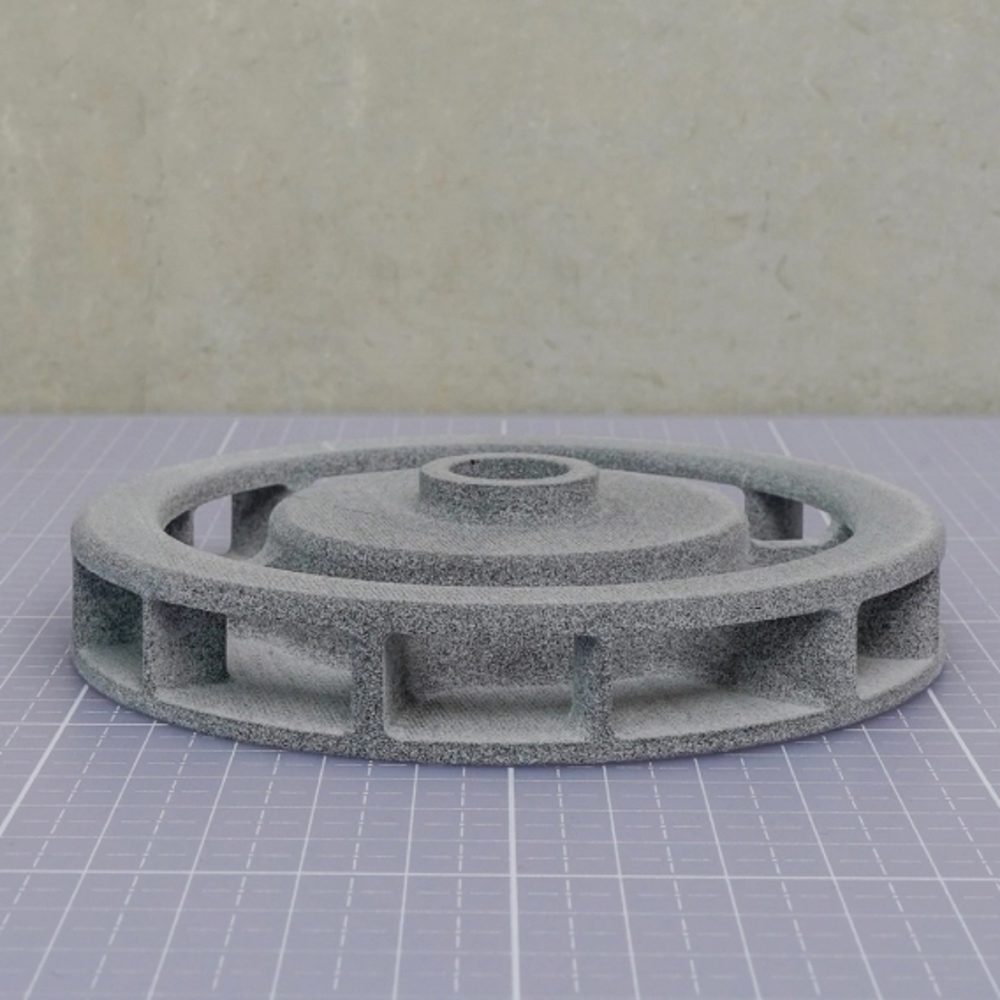

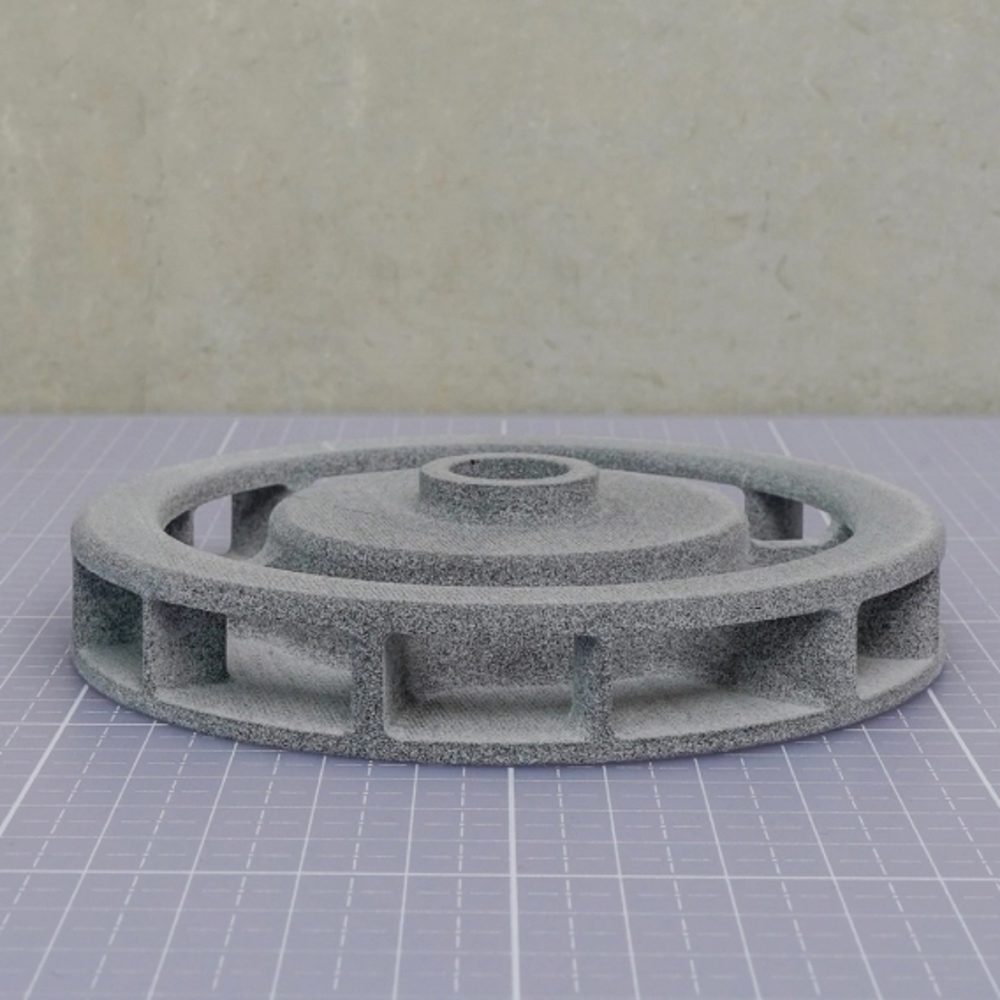

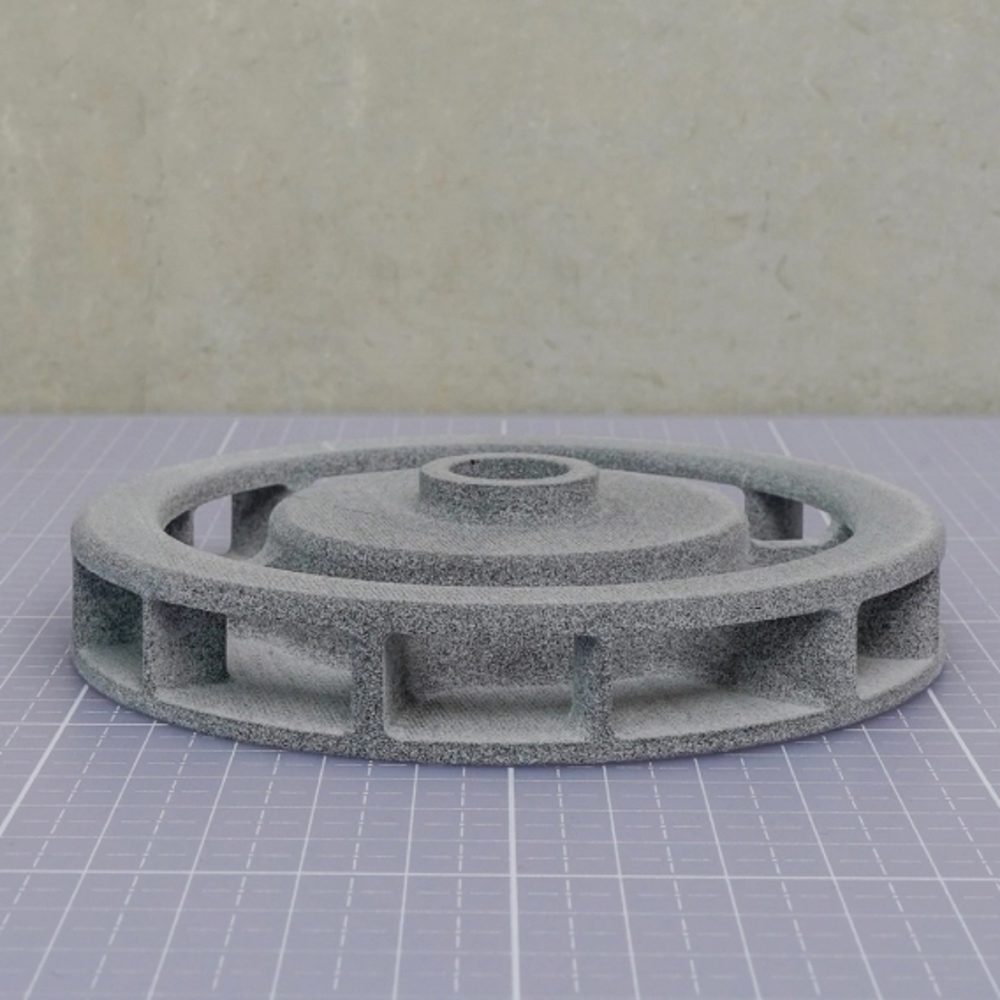

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

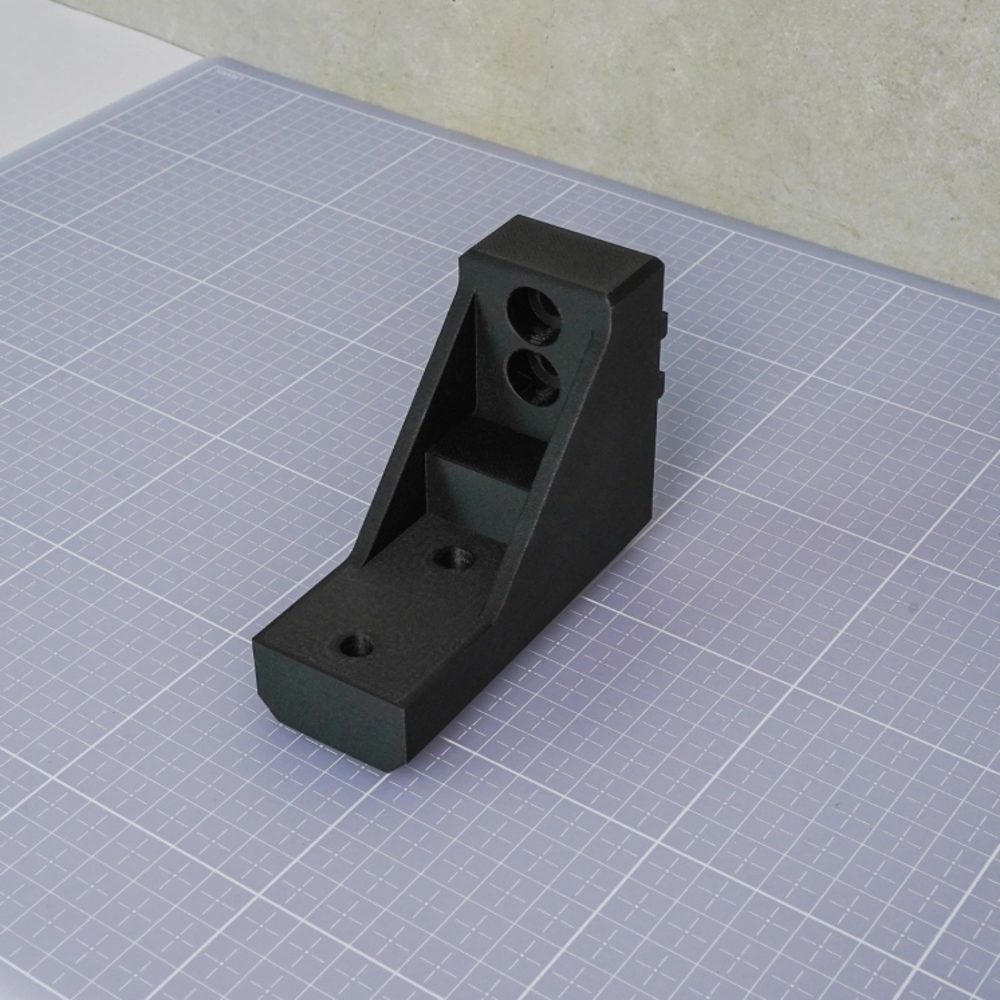

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

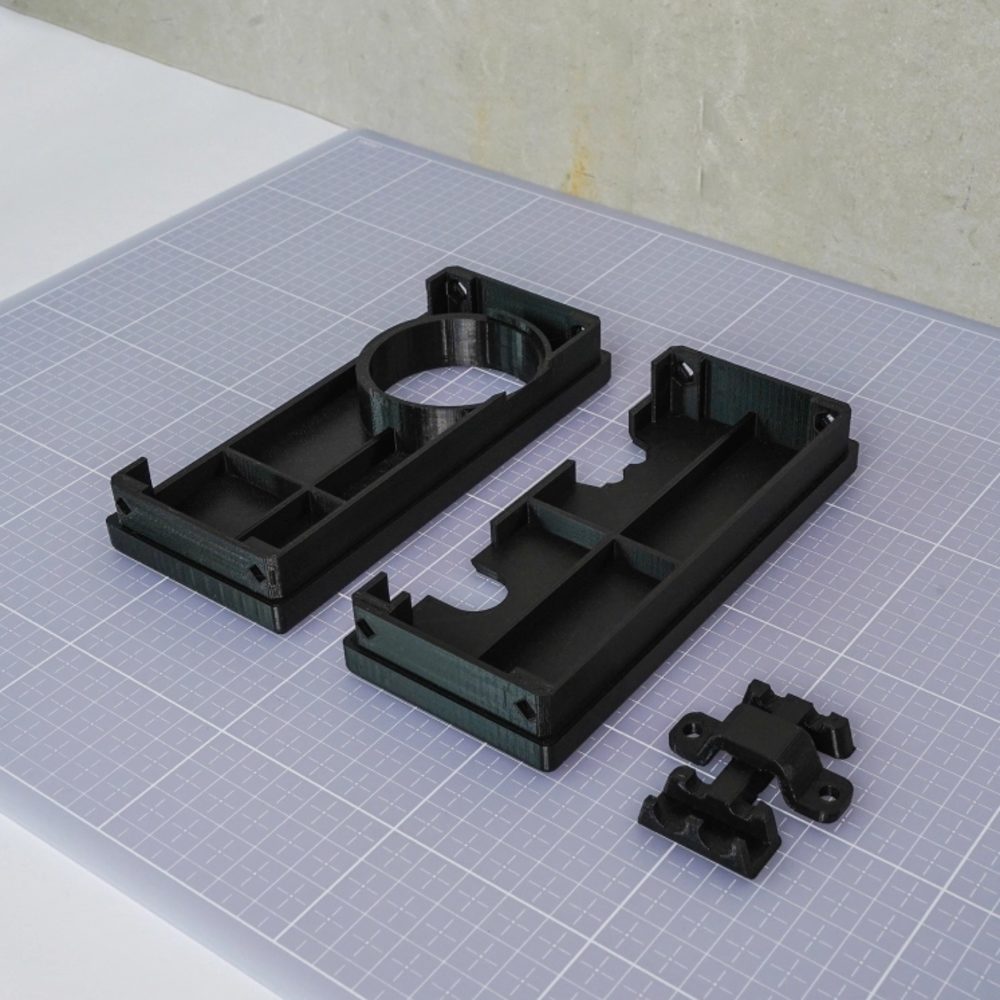

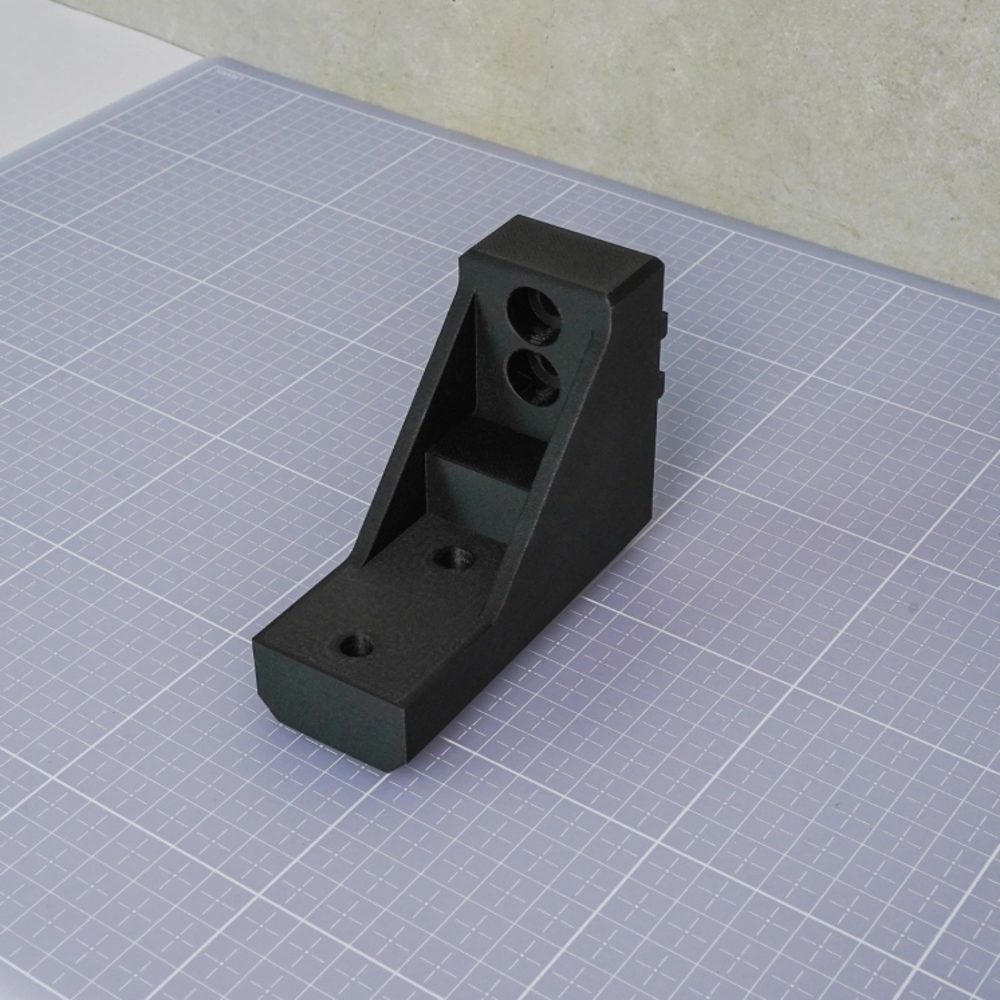

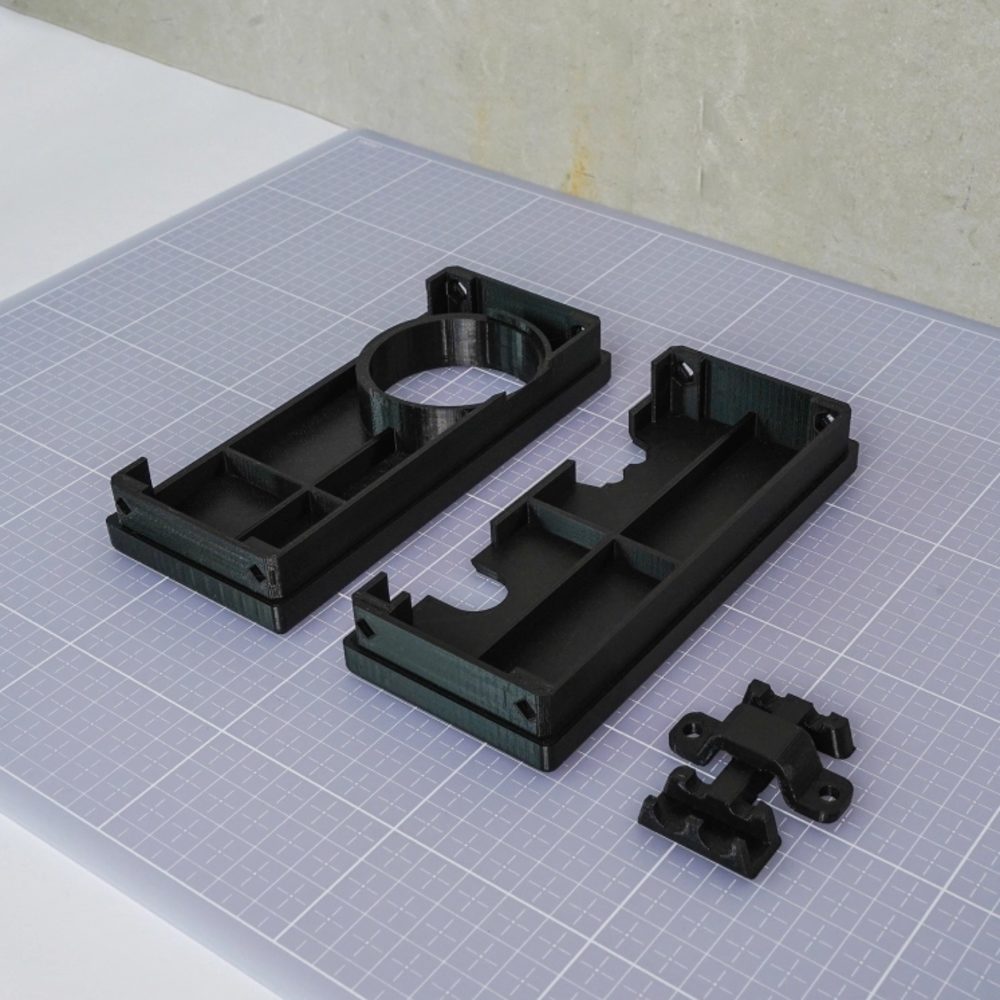

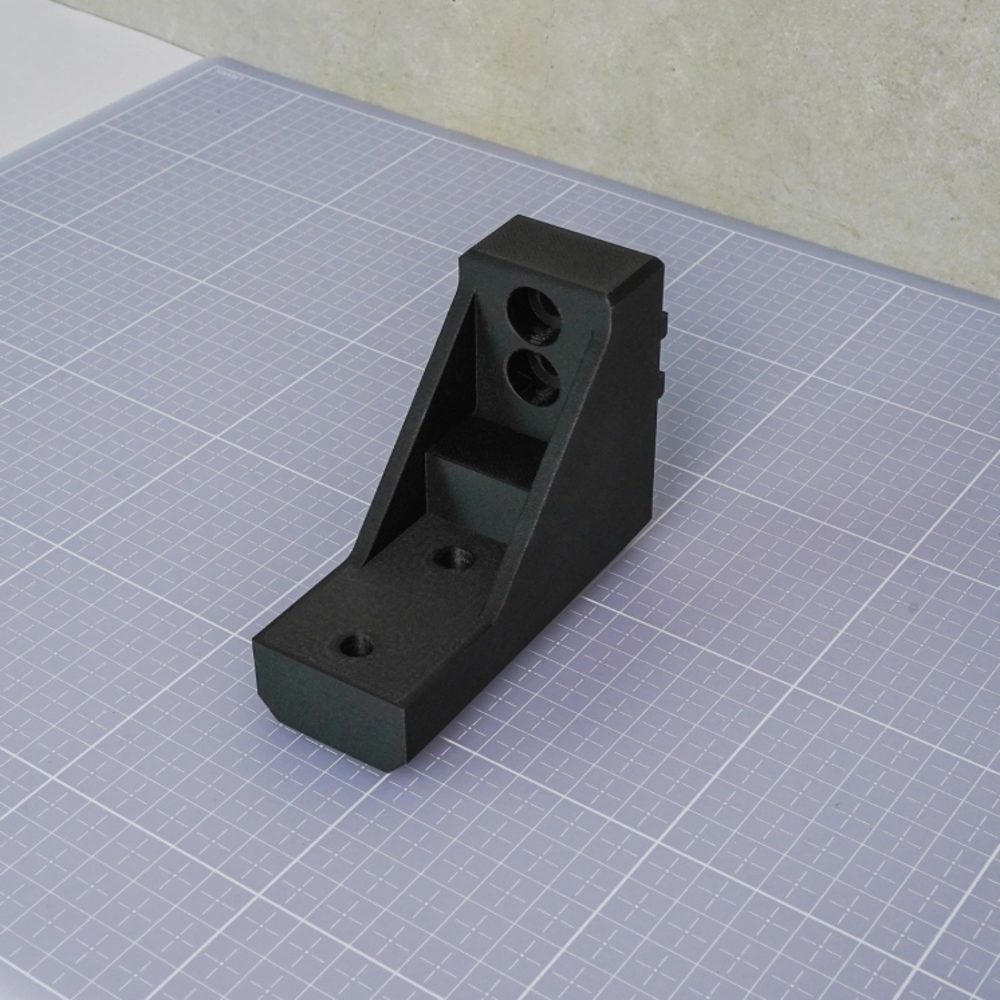

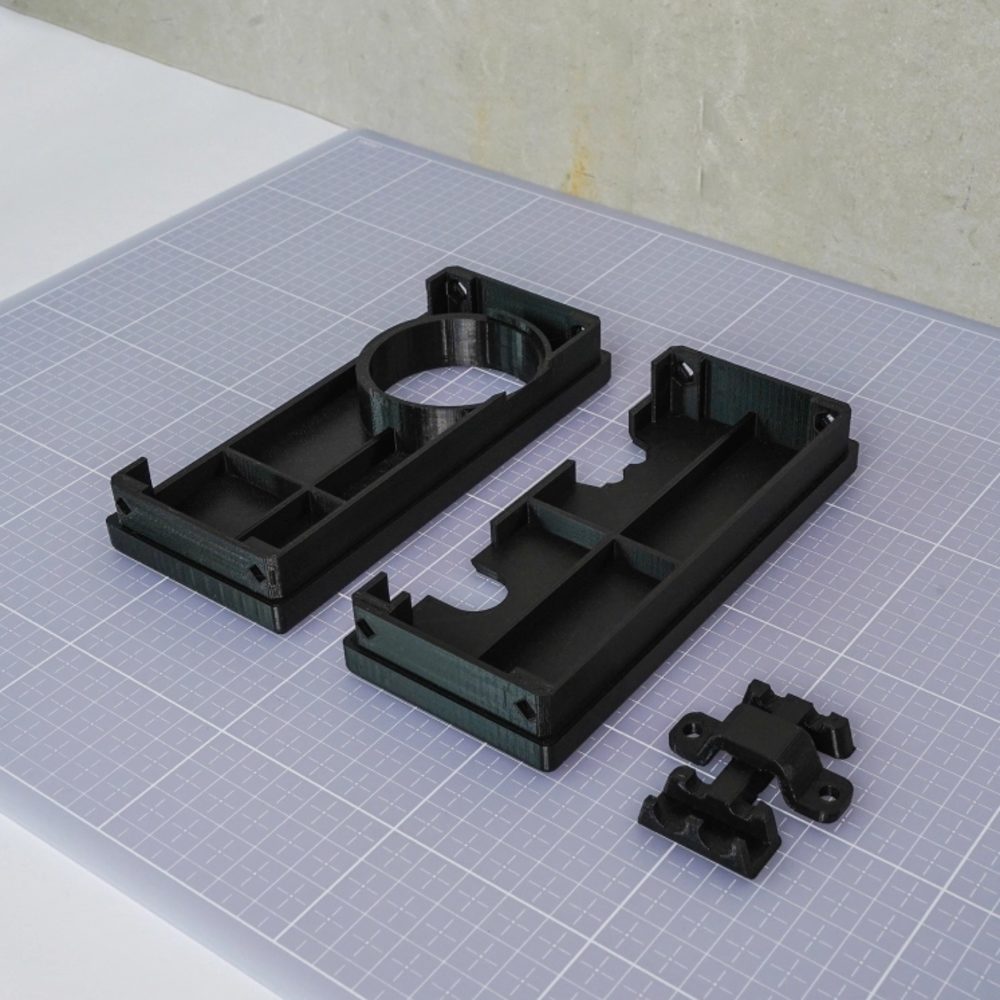

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

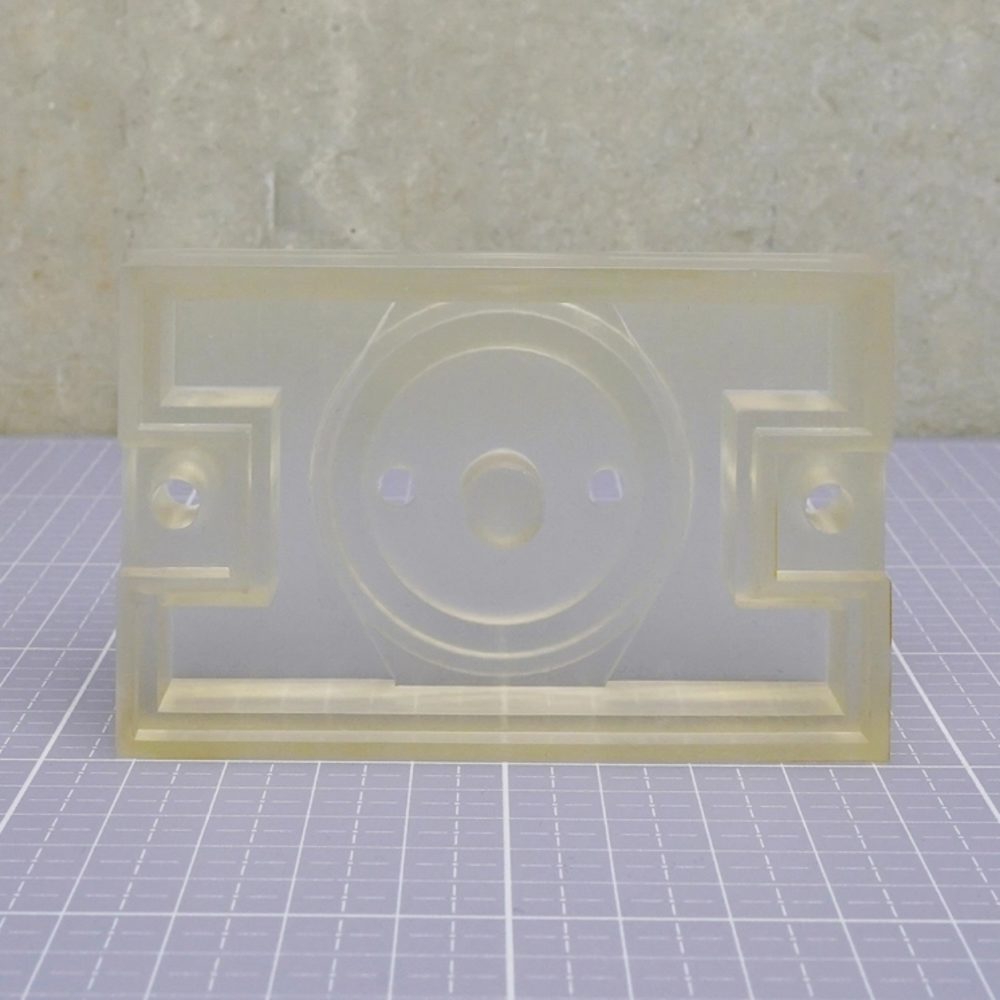

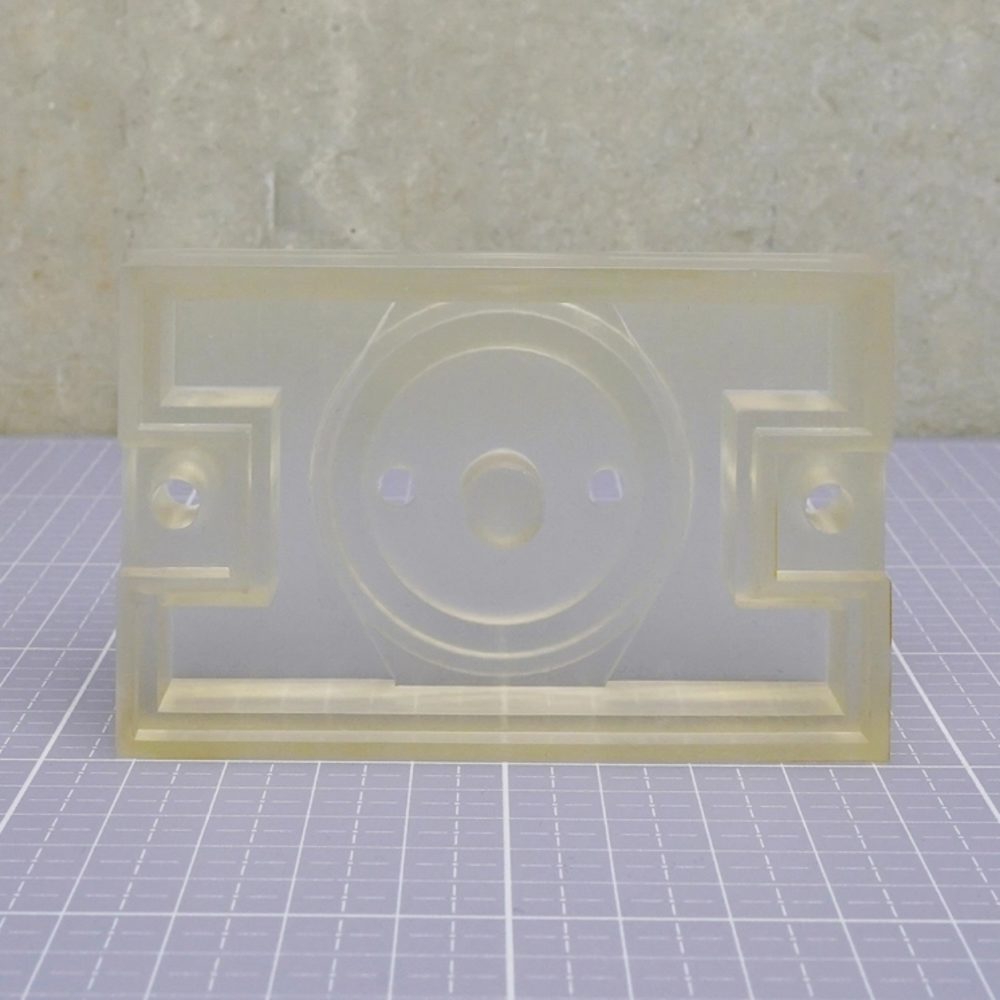

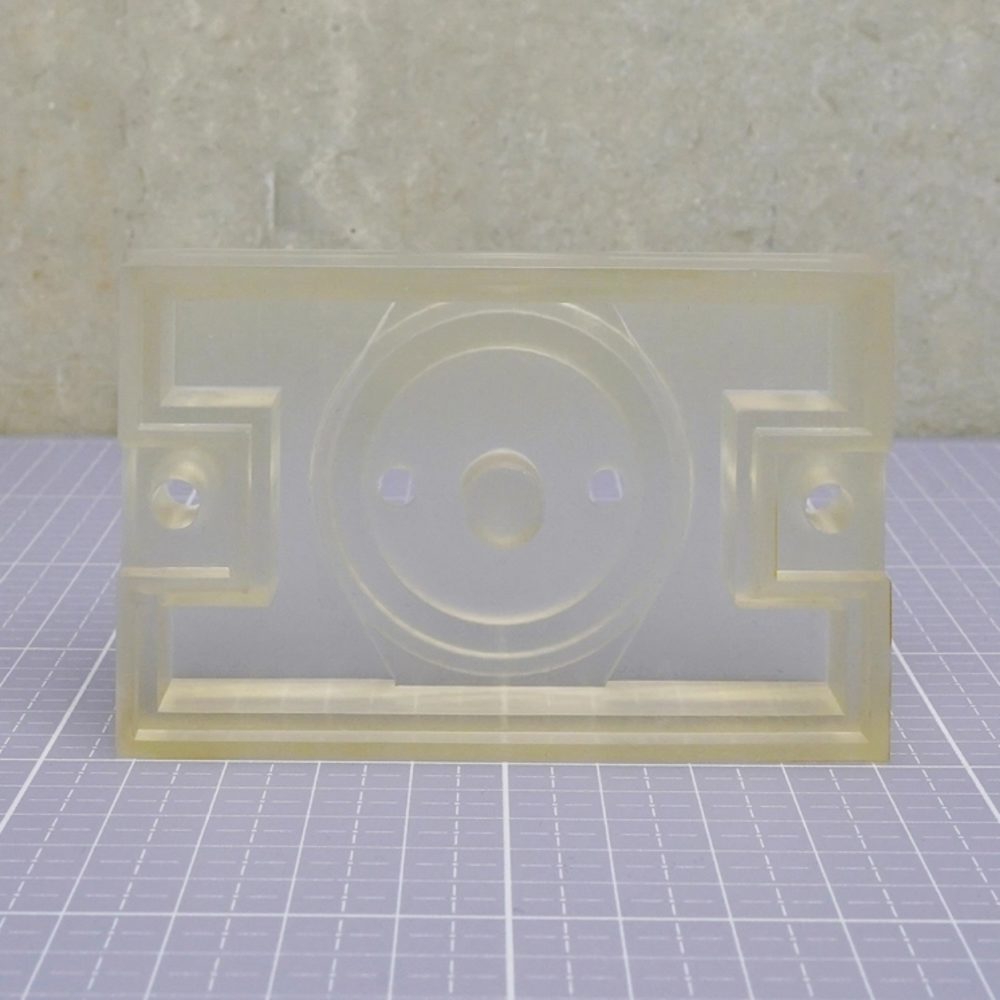

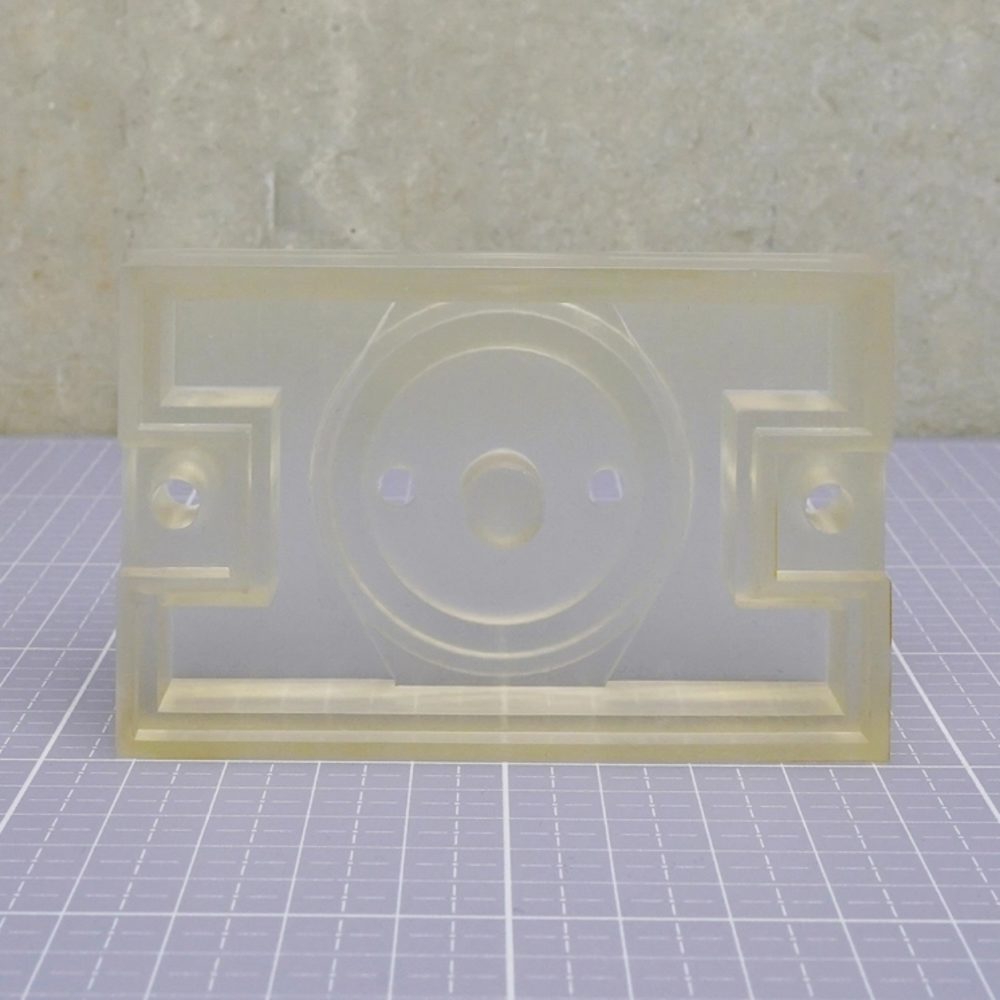

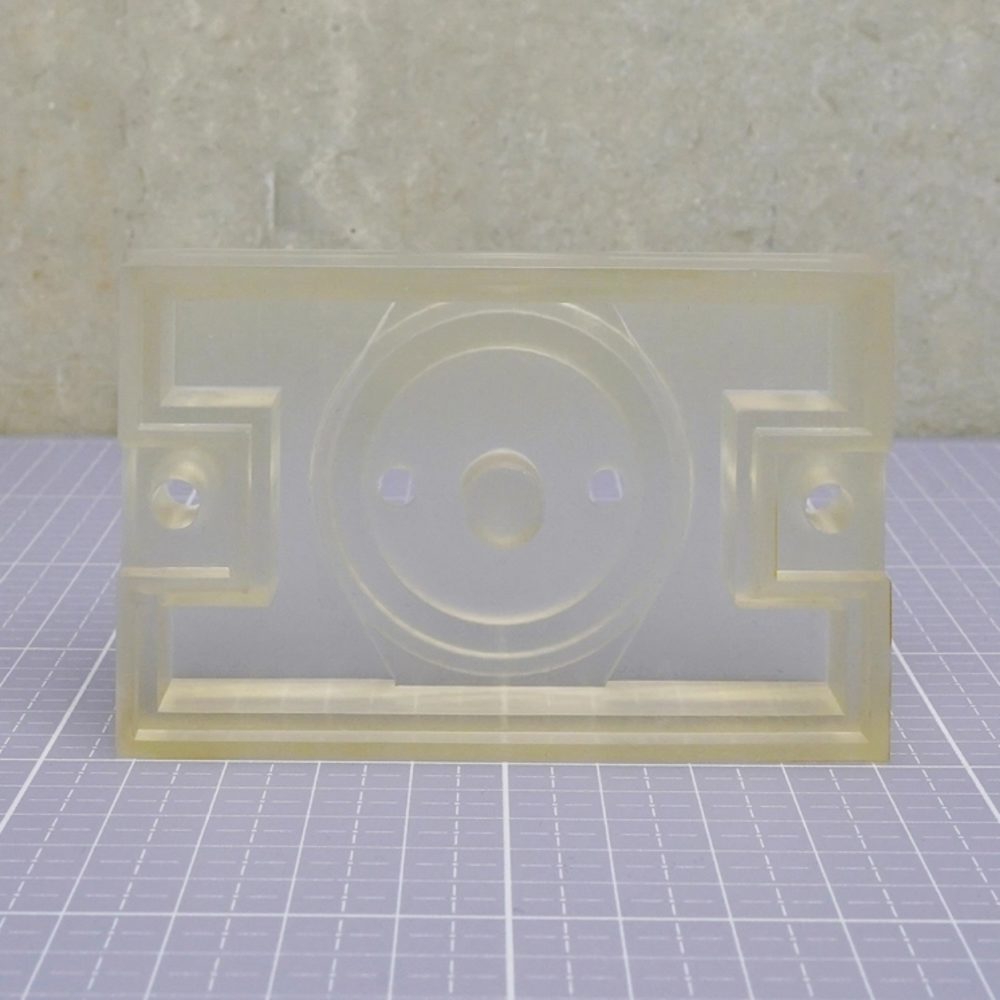

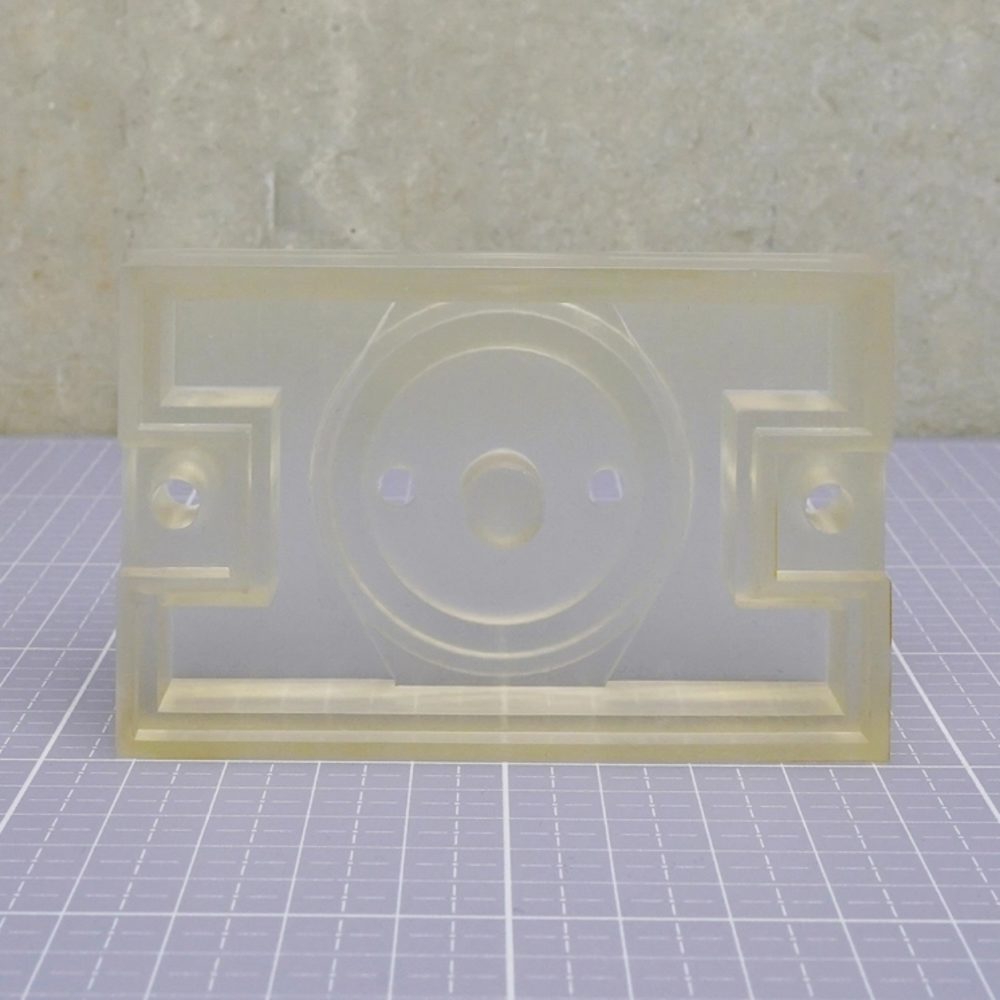

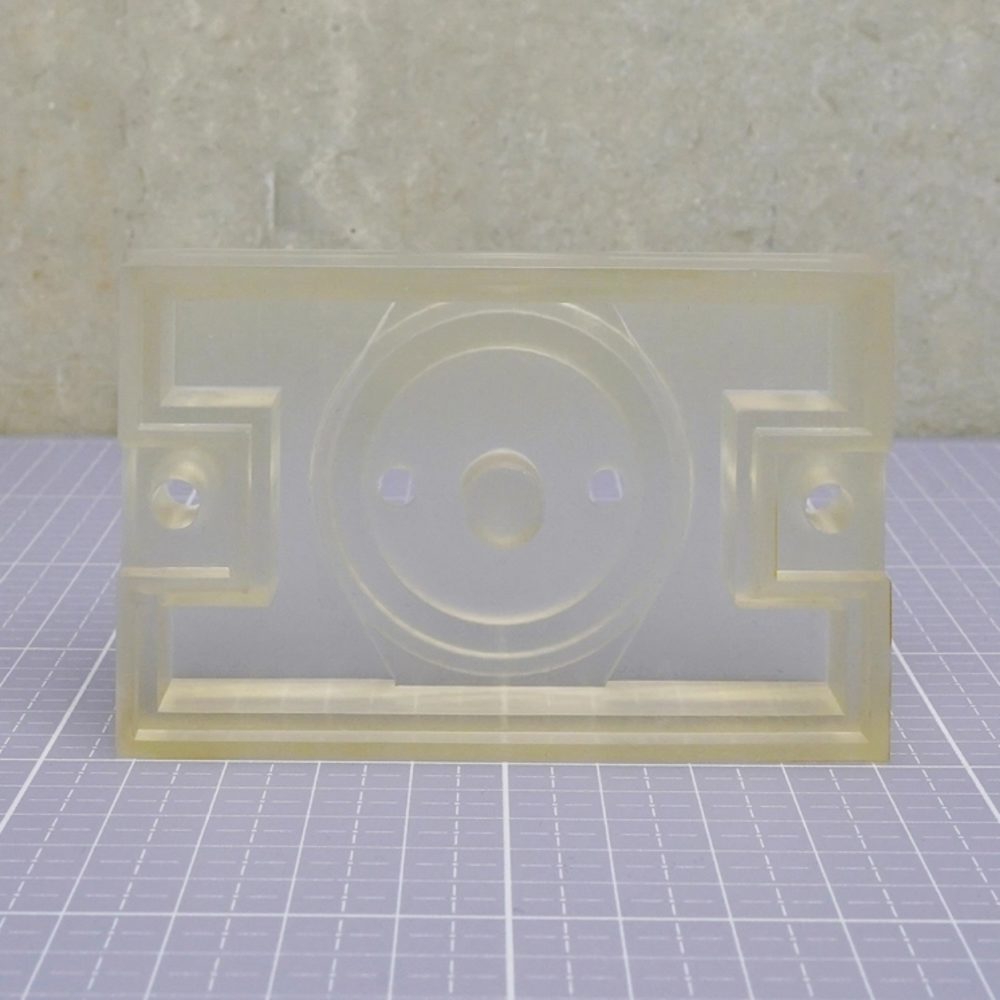

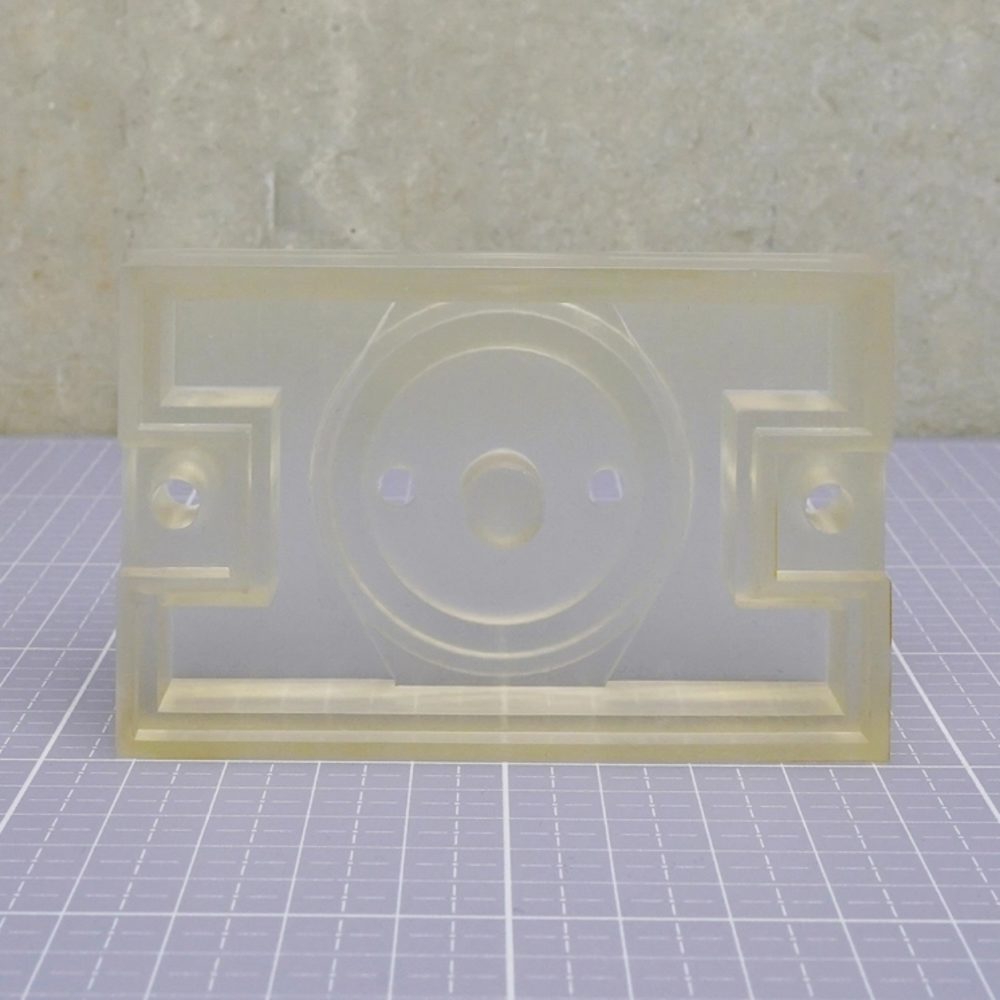

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

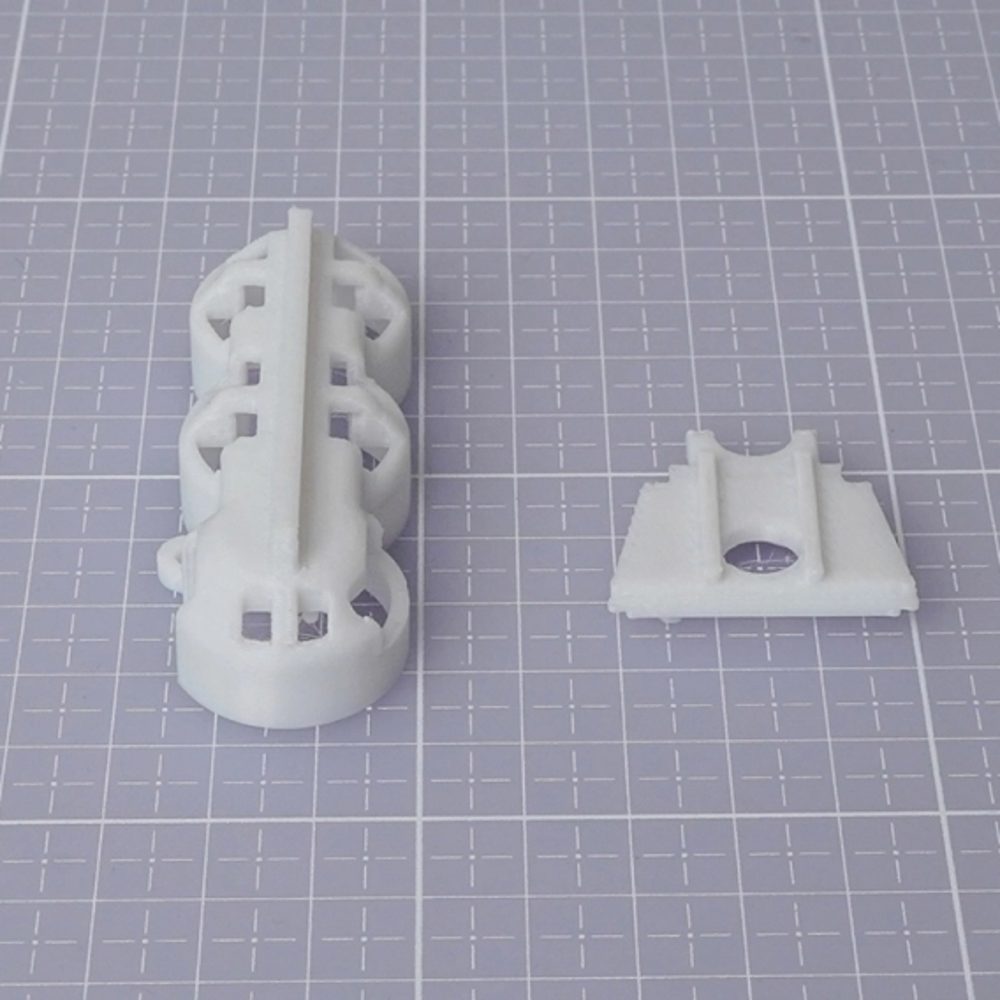

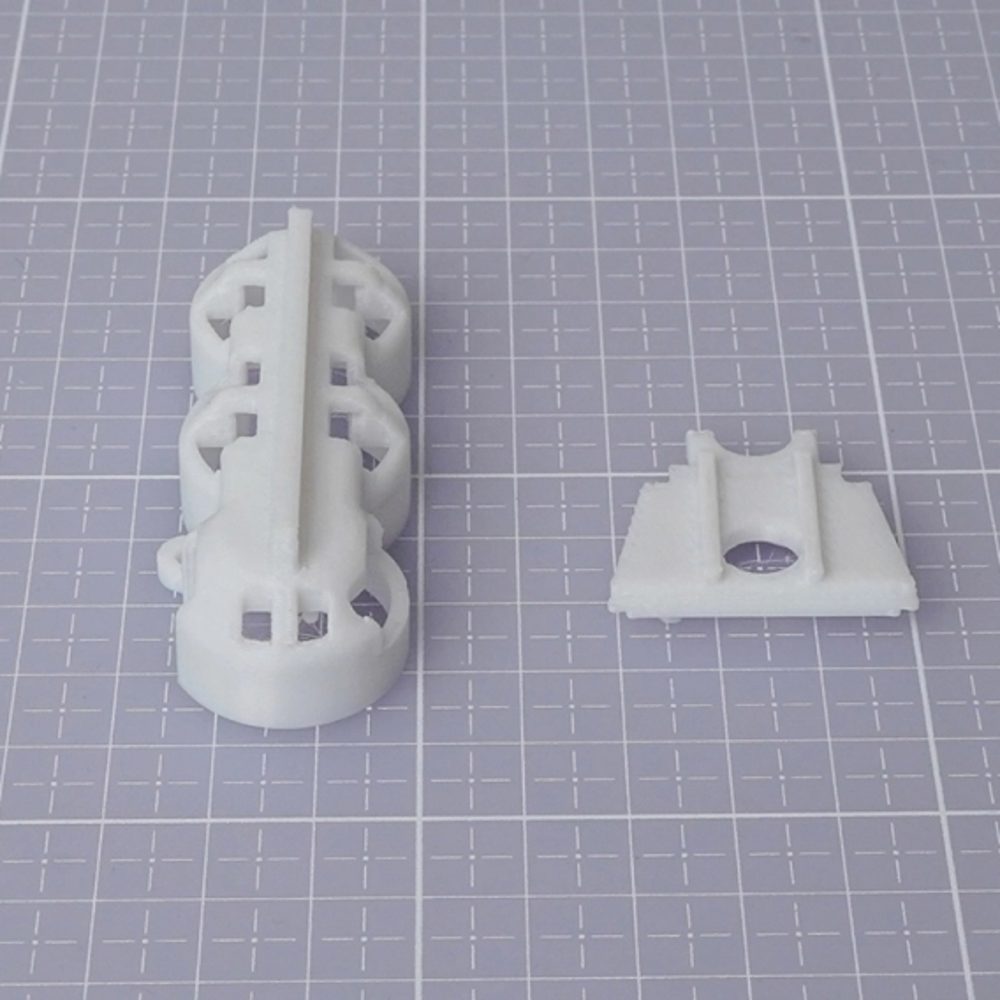

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

Aluminum 6082

| Customer | UPNA's Antenna Group |

| Purpose | A part for academic research |

| Process | CNC machining |

| Material | Aluminum 6082 |

| Surface finish | Smooth machining |

| Unit price | €299.17 |

| Industry | Research |

Aluminum 6061-T6

| Customer | ATV GmbH |

| Purpose | A part for mechanical adapters |

| Process | CNC machining |

| Material | Aluminum 6061-T6 |

| Surface finish | As machined |

| Unit price | €83.50 |

| Industry | Industrial automation |

Aluminum 7075-T6

| Purpose | A part of an enclosure for electronics for a satellite |

| Process | CNC machining |

| Material | Aluminum 7075-T6 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €36.98 |

| Industry | Aerospace |

Aluminum 6063

| Customer | Consolidated Audio |

| Purpose | Enclosure for moving coil step-up transformer |

| Process | CNC machining |

| Material | Aluminum 6063 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €61.15 |

| Industry | Electronics |

Engels machines

| Customer | Engels machines |

| Process | Injection molding |

| Material | PP |

| Surface finish | D2 |

| Industry | Agriculture |

HC Groep

| Customer | HC Groep |

| Process | Injection molding |

| Material | ABS |

| Surface finish | As machined |

| Industry | Indoor climate technology |

LEKTRI.CO

| Customer | LEKTRI.CO |

| Process | Injection molding |

| Material | PC + ABS |

| Surface finish | VDI33 |

| Industry | EV charging |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

Aluminum 6082

| Customer | UPNA's Antenna Group |

| Purpose | A part for academic research |

| Process | CNC machining |

| Material | Aluminum 6082 |

| Surface finish | Smooth machining |

| Unit price | €299.17 |

| Industry | Research |

Aluminum 6061-T6

| Customer | ATV GmbH |

| Purpose | A part for mechanical adapters |

| Process | CNC machining |

| Material | Aluminum 6061-T6 |

| Surface finish | As machined |

| Unit price | €83.50 |

| Industry | Industrial automation |

Aluminum 7075-T6

| Purpose | A part of an enclosure for electronics for a satellite |

| Process | CNC machining |

| Material | Aluminum 7075-T6 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €36.98 |

| Industry | Aerospace |

Aluminum 6063

| Customer | Consolidated Audio |

| Purpose | Enclosure for moving coil step-up transformer |

| Process | CNC machining |

| Material | Aluminum 6063 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €61.15 |

| Industry | Electronics |

Engels machines

| Customer | Engels machines |

| Process | Injection molding |

| Material | PP |

| Surface finish | D2 |

| Industry | Agriculture |

HC Groep

| Customer | HC Groep |

| Process | Injection molding |

| Material | ABS |

| Surface finish | As machined |

| Industry | Indoor climate technology |

LEKTRI.CO

| Customer | LEKTRI.CO |

| Process | Injection molding |

| Material | PC + ABS |

| Surface finish | VDI33 |

| Industry | EV charging |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

Aluminum 6082

| Customer | UPNA's Antenna Group |

| Purpose | A part for academic research |

| Process | CNC machining |

| Material | Aluminum 6082 |

| Surface finish | Smooth machining |

| Unit price | €299.17 |

| Industry | Research |

Aluminum 6061-T6

| Customer | ATV GmbH |

| Purpose | A part for mechanical adapters |

| Process | CNC machining |

| Material | Aluminum 6061-T6 |

| Surface finish | As machined |

| Unit price | €83.50 |

| Industry | Industrial automation |

Aluminum 7075-T6

| Purpose | A part of an enclosure for electronics for a satellite |

| Process | CNC machining |

| Material | Aluminum 7075-T6 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €36.98 |

| Industry | Aerospace |

Aluminum 6063

| Customer | Consolidated Audio |

| Purpose | Enclosure for moving coil step-up transformer |

| Process | CNC machining |

| Material | Aluminum 6063 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €61.15 |

| Industry | Electronics |

Engels machines

| Customer | Engels machines |

| Process | Injection molding |

| Material | PP |

| Surface finish | D2 |

| Industry | Agriculture |

HC Groep

| Customer | HC Groep |

| Process | Injection molding |

| Material | ABS |

| Surface finish | As machined |

| Industry | Indoor climate technology |

LEKTRI.CO

| Customer | LEKTRI.CO |

| Process | Injection molding |

| Material | PC + ABS |

| Surface finish | VDI33 |

| Industry | EV charging |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

Aluminum 6082

| Customer | UPNA's Antenna Group |

| Purpose | A part for academic research |

| Process | CNC machining |

| Material | Aluminum 6082 |

| Surface finish | Smooth machining |

| Unit price | €299.17 |

| Industry | Research |

Aluminum 6061-T6

| Customer | ATV GmbH |

| Purpose | A part for mechanical adapters |

| Process | CNC machining |

| Material | Aluminum 6061-T6 |

| Surface finish | As machined |

| Unit price | €83.50 |

| Industry | Industrial automation |

Aluminum 7075-T6

| Purpose | A part of an enclosure for electronics for a satellite |

| Process | CNC machining |

| Material | Aluminum 7075-T6 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €36.98 |

| Industry | Aerospace |

Aluminum 6063

| Customer | Consolidated Audio |

| Purpose | Enclosure for moving coil step-up transformer |

| Process | CNC machining |

| Material | Aluminum 6063 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €61.15 |

| Industry | Electronics |

Engels machines

| Customer | Engels machines |

| Process | Injection molding |

| Material | PP |

| Surface finish | D2 |

| Industry | Agriculture |

HC Groep

| Customer | HC Groep |

| Process | Injection molding |

| Material | ABS |

| Surface finish | As machined |

| Industry | Indoor climate technology |

LEKTRI.CO

| Customer | LEKTRI.CO |

| Process | Injection molding |

| Material | PC + ABS |

| Surface finish | VDI33 |

| Industry | EV charging |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

Aluminum 6082

| Customer | UPNA's Antenna Group |

| Purpose | A part for academic research |

| Process | CNC machining |

| Material | Aluminum 6082 |

| Surface finish | Smooth machining |

| Unit price | €299.17 |

| Industry | Research |

Aluminum 6061-T6

| Customer | ATV GmbH |

| Purpose | A part for mechanical adapters |

| Process | CNC machining |

| Material | Aluminum 6061-T6 |

| Surface finish | As machined |

| Unit price | €83.50 |

| Industry | Industrial automation |

Aluminum 7075-T6

| Purpose | A part of an enclosure for electronics for a satellite |

| Process | CNC machining |

| Material | Aluminum 7075-T6 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €36.98 |

| Industry | Aerospace |

Aluminum 6063

| Customer | Consolidated Audio |

| Purpose | Enclosure for moving coil step-up transformer |

| Process | CNC machining |

| Material | Aluminum 6063 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €61.15 |

| Industry | Electronics |

Engels machines

| Customer | Engels machines |

| Process | Injection molding |

| Material | PP |

| Surface finish | D2 |

| Industry | Agriculture |

HC Groep

| Customer | HC Groep |

| Process | Injection molding |

| Material | ABS |

| Surface finish | As machined |

| Industry | Indoor climate technology |

LEKTRI.CO

| Customer | LEKTRI.CO |

| Process | Injection molding |

| Material | PC + ABS |

| Surface finish | VDI33 |

| Industry | EV charging |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

Aluminum 6082

| Customer | UPNA's Antenna Group |

| Purpose | A part for academic research |

| Process | CNC machining |

| Material | Aluminum 6082 |

| Surface finish | Smooth machining |

| Unit price | €299.17 |

| Industry | Research |

Aluminum 6061-T6

| Customer | ATV GmbH |

| Purpose | A part for mechanical adapters |

| Process | CNC machining |

| Material | Aluminum 6061-T6 |

| Surface finish | As machined |

| Unit price | €83.50 |

| Industry | Industrial automation |

Aluminum 7075-T6

| Purpose | A part of an enclosure for electronics for a satellite |

| Process | CNC machining |

| Material | Aluminum 7075-T6 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €36.98 |

| Industry | Aerospace |

Aluminum 6063

| Customer | Consolidated Audio |

| Purpose | Enclosure for moving coil step-up transformer |

| Process | CNC machining |

| Material | Aluminum 6063 |

| Surface finish | Bead blasted + Anodized type ll (Matte) |

| Unit price | €61.15 |

| Industry | Electronics |

Engels machines

| Customer | Engels machines |

| Process | Injection molding |

| Material | PP |

| Surface finish | D2 |

| Industry | Agriculture |

HC Groep

| Customer | HC Groep |

| Process | Injection molding |

| Material | ABS |

| Surface finish | As machined |